Synthesis and Application of Water-Soluble Dibasic Ester

A dibasic acid ester, water-soluble technology, applied in the field of organic chemical synthesis, can solve the problems of large environmental pollution, chemical properties can not meet the actual use requirements of metalworking fluids, etc., and achieves low reaction temperature, good lubricity, and low addition amount. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

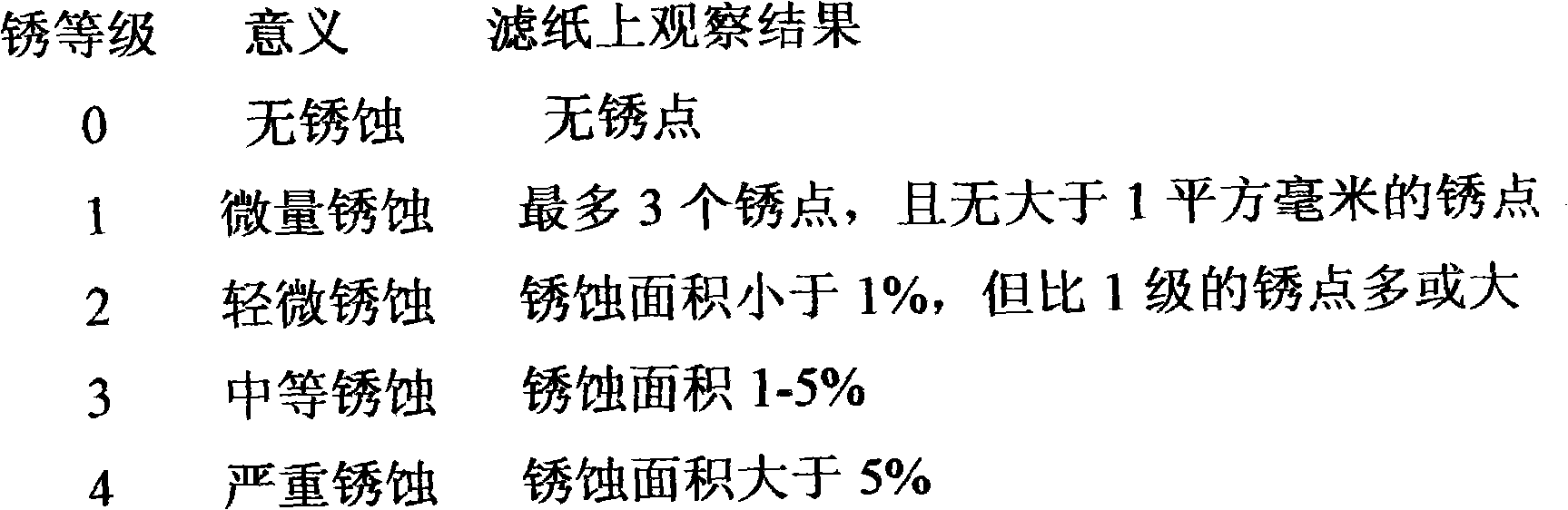

[0031] Weigh 150g of polyethylene glycol 600 and 27g of undecanedibasic acid into a flat-bottomed flask, stir well and add 0.354g of N-alkylpyrrolidone-containing group Acid ionic liquid catalyst, stirring, heating, controlling the temperature at 110°C, and reacting for 4 hours to obtain the final product. The reaction product is an orange-yellow viscous liquid with an acid value of 71.5 mgKOH / g. After adjusting the pH value of the product to 9.0 with diethanolamine, prepare a 5% working solution with tap water, and carry out the rust prevention test of cast iron chips according to the following method, and the rust resistance is 4 grades:

[0032] Antirust test method of cast iron shavings:

[0033] Take the filter paper and put it into a petri dish, weigh 2g±0.1g of cast iron filings, spread it on the filter paper, pipette 2ml of the solution to be tested, wet all the iron filings, cover the petri dish at 18-28 degrees Celsius for 2 hours, remove For cast iron chips, rinse...

Embodiment 2

[0037] Weigh 165g of polyethylene glycol 600 and 27g of undecanedibasic acid into a flat-bottomed flask, stir well and add 0.384g of N-alkylpyrrolidone group Acid ionic liquid catalyst, stirring, heating, controlling the temperature at 120°C, and reacting for 5 hours to obtain the final product. The reaction product is an orange-yellow viscous liquid with an acid value of 68 mgKOH / g. After the pH value of the product was adjusted to 9.0 with diethanolamine, a 5% working solution was prepared with tap water. According to the test method for rust prevention of cast iron chips in Example 1, the rust resistance was grade 4.

Embodiment 3

[0039] Weigh 187.5g of polyethylene glycol 600 and 27g of undecanedibasic acid into a flat-bottomed flask, stir well and add 0.429g of N-alkylpyrrolidone-containing group Acid ionic liquid catalyst, stirring, heating, controlling the temperature at 130°C, and reacting for 6 hours to obtain the final product. The reaction product is an orange-yellow viscous liquid with an acid value of 6.2 mgKOH / g. After adjusting the pH value of the product to 9.0 with diethanolamine, prepare a 5% working solution with tap water, and measure the rust resistance according to the cast iron scrap rust prevention test method of Example 1 to be grade 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com