Cysteine coupled protein grafted regenerated cellulose fiber material and preparation method thereof

A cysteine-coupled protein, regenerated cellulose technology, applied in fiber processing, plant fibers, textiles and papermaking, etc., can solve problems such as destroying cellulose structure and affecting fiber properties, achieving broad application prospects and improving mechanical properties. performance, the effect of improving graft fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

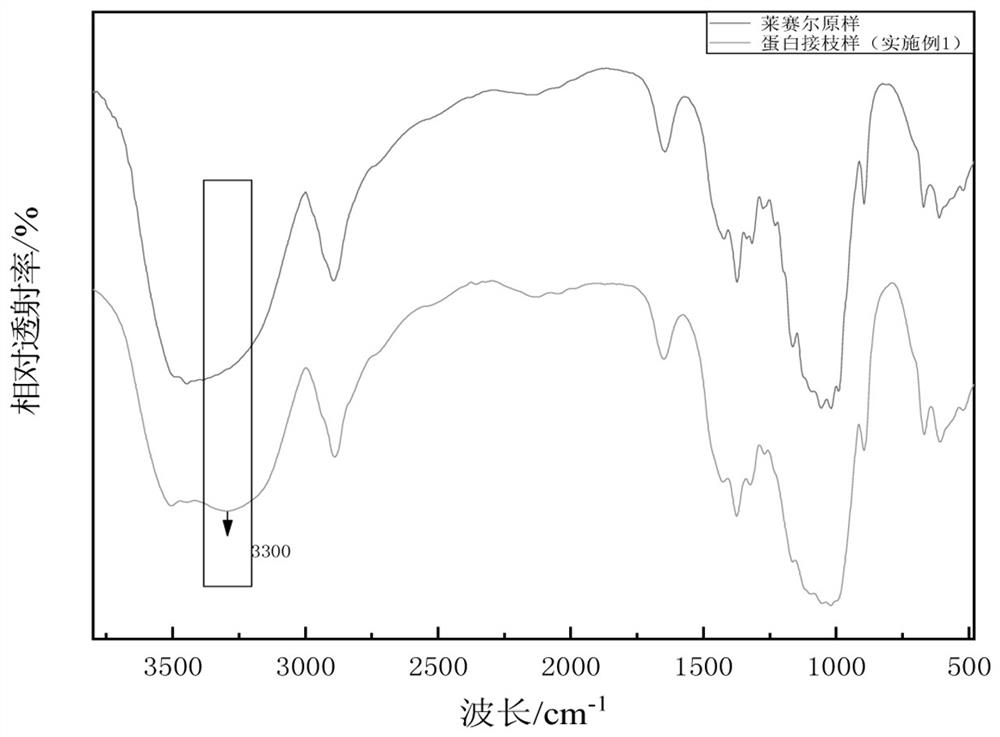

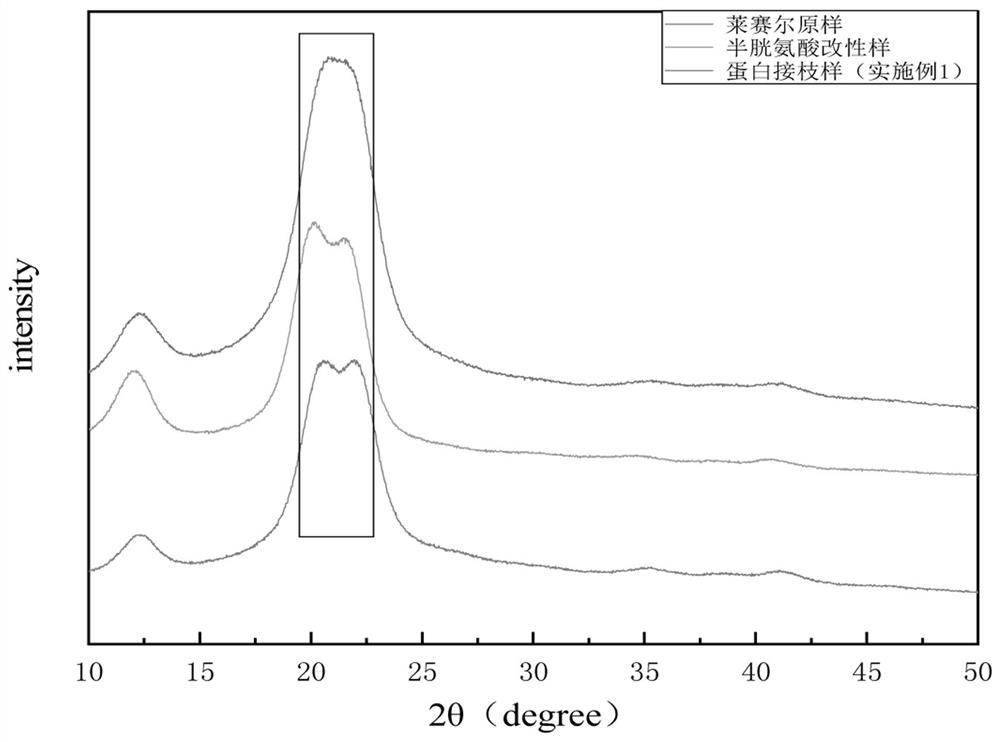

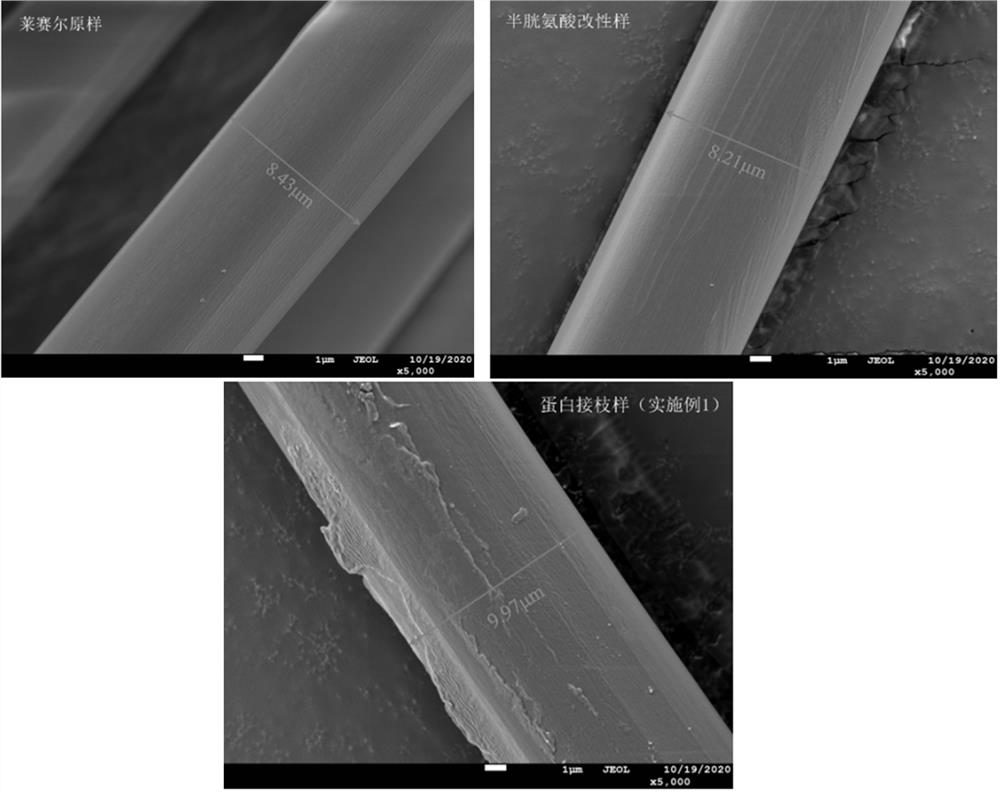

[0035] Taking a representative protein---collagen as an example, take 2g of regenerated cellulose fiber (taking lyocell fiber as an example), wash it three times with deionized water, and prepare 100ml of sodium hydroxide solution with a mass fraction of 2%. , take out the washed fiber, put it into the prepared sodium hydroxide solution, completely impregnate the fiber with a glass rod, put it into a constant temperature water bath at 40°C, stir and wash it with a glass rod for 10 minutes, and take it out Fiber, then put the fiber into 50ml of absolute ethanol solution, completely impregnate the fiber with a glass rod, put it into a constant temperature water bath at 40°C, stir and wash it with a glass rod for 8min, take out the fiber and wait for ethanol Volatile, and then put into the oven to dry to constant weight.

[0036] The preparation mass fraction is 8% H 2 o 2 solution, add impurity-removing regenerated cellulose fibers and stir evenly, react in a constant temperat...

Embodiment 2

[0040] Taking a representative protein---collagen as an example, take 2g of regenerated cellulose fiber (taking lyocell fiber as an example), wash it three times with deionized water, and prepare 100ml of sodium hydroxide solution with a mass fraction of 2%. , take out the washed fiber, put it into the prepared sodium hydroxide solution, completely impregnate the fiber with a glass rod, put it into a constant temperature water bath at 40°C, stir and wash it with a glass rod for 10 minutes, and take it out Fiber, then put the fiber into 50ml of absolute ethanol solution, completely impregnate the fiber with a glass rod, put it into a constant temperature water bath at 40°C, stir and wash it with a glass rod for 8min, take out the fiber and wait for ethanol Volatile, and then put into the oven to dry to constant weight.

[0041] Prepare H with a mass fraction of 10% 2 o 2 solution, add impurity-removing regenerated cellulose fibers and stir evenly, react in a constant temperat...

Embodiment 3

[0045] Taking a representative protein---collagen as an example, take 2g of regenerated cellulose fiber (taking lyocell fiber as an example), wash it three times with deionized water, and prepare 100ml of sodium hydroxide solution with a mass fraction of 2%. , take out the washed fiber, put it into the prepared sodium hydroxide solution, completely impregnate the fiber with a glass rod, put it into a constant temperature water bath at 40°C, stir and wash it with a glass rod for 10 minutes, and take it out Fiber, then put the fiber into 50ml of absolute ethanol solution, completely impregnate the fiber with a glass rod, put it into a constant temperature water bath at 40°C, stir and wash it with a glass rod for 8min, take out the fiber and wait for ethanol Volatile, and then put into the oven to dry to constant weight.

[0046] Prepare 100ml of cysteine solution with a mass fraction of 4%, adjust its pH value to 7.0 with sodium hydroxide, then put the oxidized fiber into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com