A mesoporous coco 3 /g-c 3 no 4 Preparation method of composite material

A composite material, g-c3n4 technology, applied in the field of preparation of mesoporous CoCO3/g-C3N4 composite materials, can solve the problems of insufficient utilization of visible light, high carrier recombination rate, weak light absorption ability, etc. Catalytic hydrogen production performance, simple production process, and improved separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: CoCO 3 / g -C 3 N 4 Preparation of composite materials

[0032] (1) Weigh urea, dry it in an oven at 80 °C for 24 h, grind it evenly, put it into a crucible with a cover, and place it in a muffle furnace at 2.5 °C min -1 Heating rate of , heating from room temperature to 550 ℃, holding for 4 h; in 1 mol L -1 Stir in nitric acid for 12 h, perform suction filtration, wash with deionized water until neutral, and dry in an oven for 24 h; grind evenly and finely, spread it in a square porcelain boat, wrap it in tin foil, and put it in a muffle furnace at 5°C min -1 Heating rate of , heating from room temperature to 500 ℃ for 4 h, to obtain g-C 3 N 4 catalyst of light.

[0033] (2) Weigh 0.5818 g of cobalt nitrate hexahydrate, dissolve it in a mixed solution consisting of 7 ml of glycerol and 23 ml of distilled water and stir thoroughly for 30 min, add 0.5 g of urea and stir for 30 min until the urea is fully dissolved, and put it into the capacity In a 50ml...

Embodiment 2

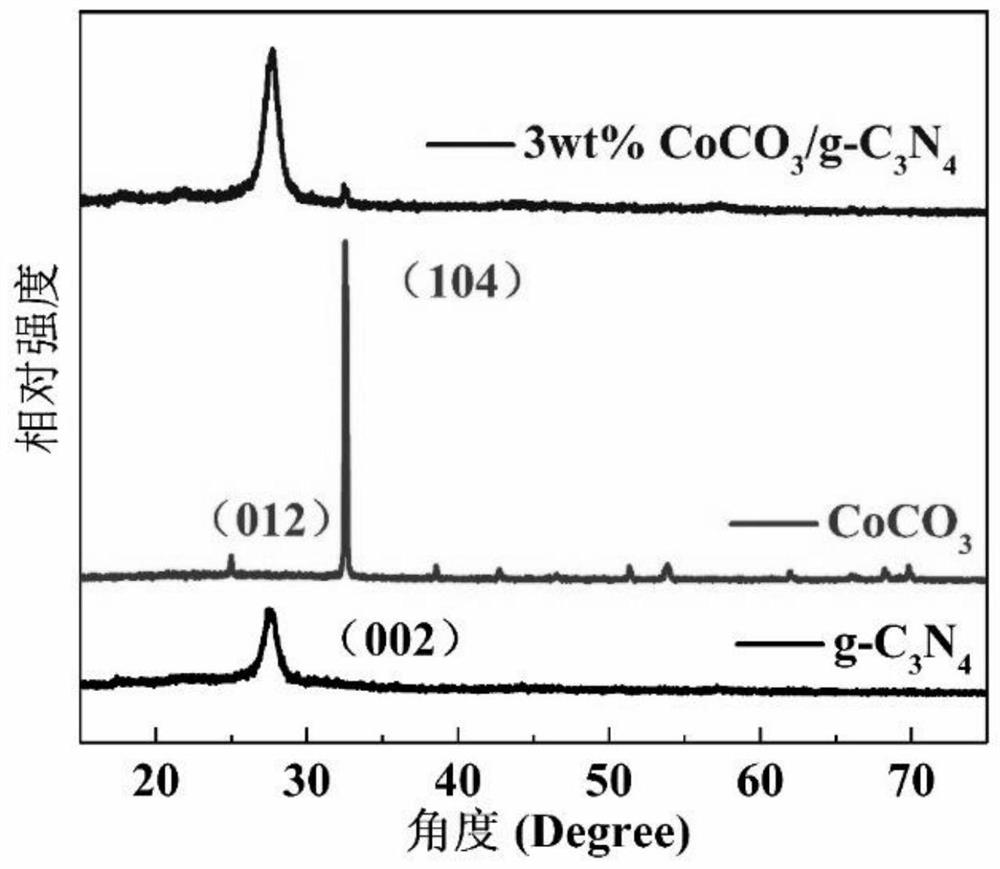

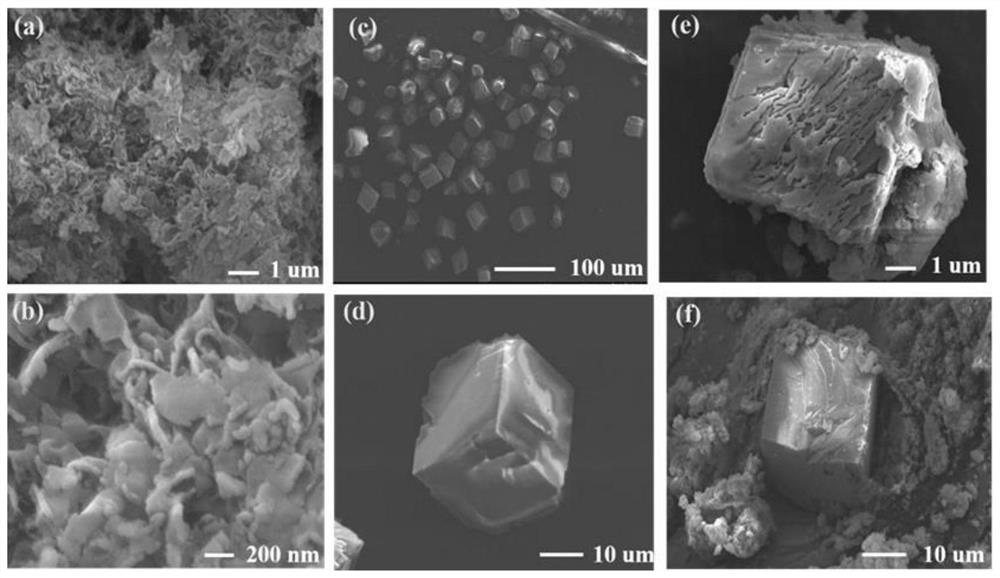

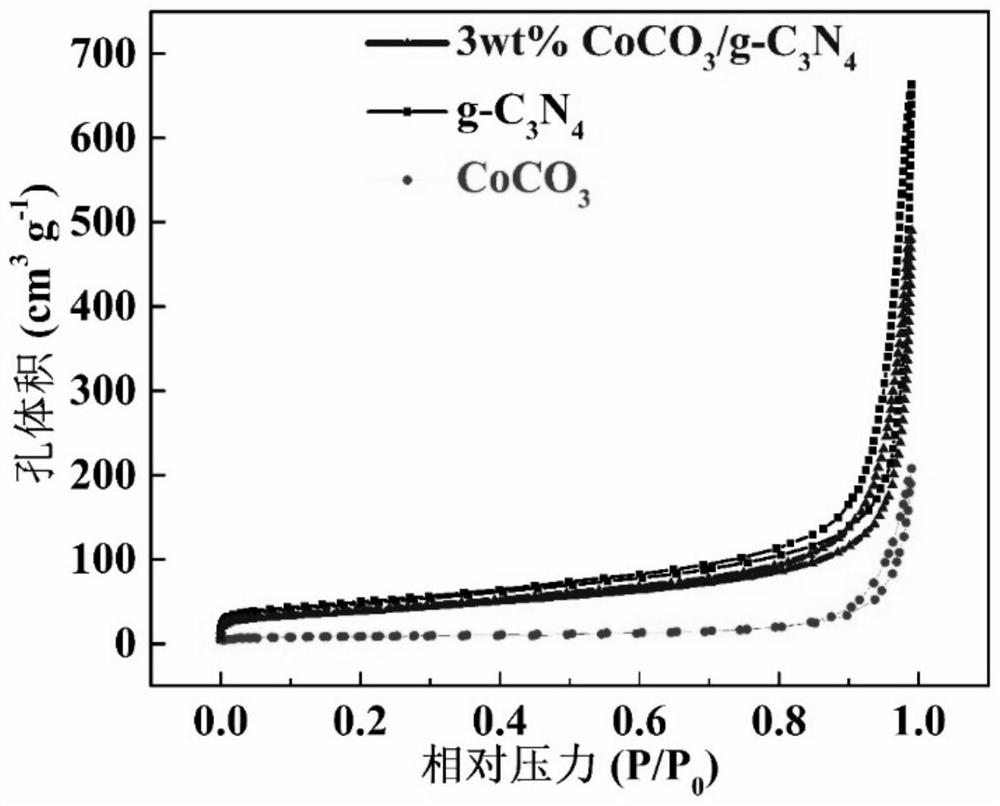

[0036] Example 2: Mesoporous CoCO 3 / g -C 3 N 4 Performance Analysis of Composite Materials

[0037] In this example, X-ray diffraction (XRD), scanning electron microscopy (SEM), N 2 Adsorption-desorption isotherm, BJH pore size distribution, instantaneous photocurrent response (I-t) and other means for the mesoporous CoCO prepared in Example 1 3 / g -C 3 N 4 Composites are tested for performance. g-C 3 N 4 Catalyst and CoCO 3 A single catalyst was used as a reference for comparison. CoCO 3 The preparation method of the monomer catalyst is to use 0.1 g of the CoCO obtained in step (2) of Example 1 3 The precursor was directly dissolved in 30 ml ethanol solution and stirred for 1 h, then dried in an oven at 80 °C for 12 h, and the solid product was spread in a square porcelain boat, wrapped tightly with tin foil, and placed in a muffle furnace for 2 °C min -1 The heating rate was heated from room temperature to 300 °C and kept for 2 h. After cooling to room temperatu...

Embodiment 3

[0044] Example 3: Mesoporous CoCO 3 / g -C 3 N 4 Preparation of composite materials

[0045] Weigh 0.5818 g of cobalt nitrate hexahydrate, dissolve in a mixed solution consisting of 7 ml of glycerol and 23 ml of distilled water and stir thoroughly for 30 min, add 2 g of urea and stir for 30 min until the urea is fully dissolved; put it into the reaction kettle, Hydrothermal reaction at 190 °C for 20 h, after natural cooling to room temperature, washing with deionized water and ethanol three times, respectively, and drying in an oven at 50 °C to obtain CoCO 3 Precursor;

[0046] Weigh 0.3 g of the g-C obtained in step (1) of Example 1 3 N 4 , dissolved in 60 ml ethanol solution and ultrasonically dispersed for 1 h, and added 0.009 g of CoCO obtained in step (2) 3 The precursor was stirred for 1 h and dried in an oven at 70 °C for 14 h. The solid product was spread in a square porcelain boat, wrapped tightly with tin foil, and then placed in a muffle furnace for 2.5 °C min....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com