Preparation method of nano zirconia precursor

A nano-zirconia, precursor technology, applied in the field of materials to achieve the effects of no waste discharge, safe operation and high product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

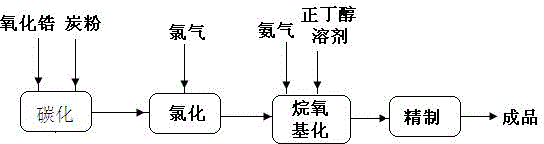

Method used

Image

Examples

Embodiment 1

[0021] 3. Alkoxylation, add zirconium tetrachloride and n-butanol into the reaction kettle according to the stoichiometric amount, add the solvent petroleum ether and stir until the zirconium chloride dissolves, feed ammonia gas until the system is alkaline, and the pH is 8- 10. Filter and wash the filter cake, collect the filtrate and washing liquid, which is tetra-n-butoxy zirconium solution, and the filter cake is ammonium chloride;

[0022] 4. Refining, mix the filtrate with the washing liquid, add solid decolorizing agent activated carbon, stir and heat to 80°C, keep warm for 30 minutes, filter out the decolorizing agent, distill the solution until the content of tetra-n-butoxy zirconium is ≥ 80%, and obtain the finished product after fine filtration .

[0023] Above-mentioned embodiment 1 is with n-butanol as alkoxy group donor, and the product obtained is tetra-n-butoxy zirconium; It can also be raw material that methanol, ethanol or propanol, the product obtained are t...

Embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com