Preparation method of tension-resistant medical conduit material and application thereof

A medical catheter and stretch-resistant technology, applied in the direction of catheters, etc., can solve problems such as insufficient stretch-resistant performance, and achieve the effect of improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

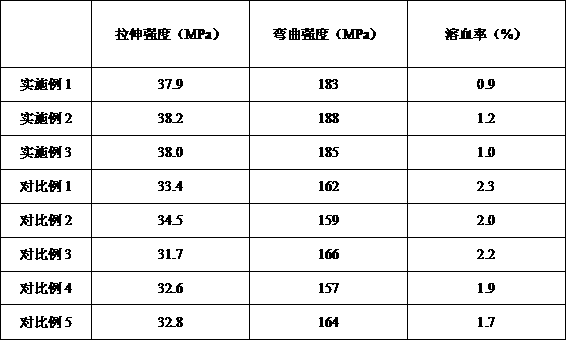

Examples

Embodiment 1

[0024] (1) Put 3 parts of wollastonite powder and 2 parts of calcium hydroxide into the ball mill, and then add 95% ethanol solution of 2 times the mass of the solid mixture to it for wet ball milling. The ball-to-material ratio of the ball mill is 10:1 , the ball milling speed is 500 rpm, the ball milling time is 60 minutes, and then the mixed powder obtained by ball milling is placed in a vacuum drying oven at a temperature of 60° C. for 6 hours to obtain a dry mixed powder;

[0025] (2) Add 35 parts of methacrylate and 30 parts of ethylene glycol dimethacrylate into the vacuum reactor, evacuate to -0.08 MPa, set the temperature in the reactor to 160°C, and set the temperature in the reactor at 150 rpm Perform high-temperature stirring reaction at a stirring rate for 45 minutes, then lower the temperature in the reactor to 120°C, add 8 parts of methyl phenyl silicone oil, stir evenly at a stirring rate of 150 rpm, and then let it stand for heat preservation reaction 30 minut...

Embodiment 2

[0032] (1) Put 4 parts of wollastonite powder and 3 parts of calcium hydroxide into the ball mill, and then add an ethanol solution with a concentration of 2 times the mass of the solid mixture to it for wet ball milling. The ball-to-material ratio of the ball mill is 10:1 , the ball milling speed is 500 rpm, the ball milling time is 75 minutes, and then the mixed powder obtained by ball milling is placed in a vacuum drying oven and dried at a temperature of 65° C. for 7 hours to obtain a dry mixed powder;

[0033](2) Add 40 parts of methacrylate and 35 parts of ethylene glycol dimethacrylate into the vacuum reactor, evacuate to -0.09 MPa, set the temperature in the reactor to 170°C, and set the temperature at 155 rpm Perform high-temperature stirring reaction at a stirring rate for 50 minutes, then lower the temperature in the reactor to 120°C, add 10 parts of methyl phenyl silicone oil, stir evenly at a stirring rate of 155 rpm, and then let it stand for heat preservation rea...

Embodiment 3

[0040] (1) Put 5 parts of wollastonite powder and 4 parts of calcium hydroxide into the ball mill, and then add an ethanol solution with a concentration of 2 times the mass of the solid mixture to it for wet ball milling. The ball-to-material ratio of the ball mill is 10:1 , the ball milling speed is 500 rpm, the ball milling time is 90 minutes, and then the mixed powder obtained by ball milling is placed in a vacuum drying oven and dried at a temperature of 70° C. for 8 hours to obtain a dry mixed powder;

[0041] (2) Add 45 parts of methacrylate and 40 parts of ethylene glycol dimethacrylate into the vacuum reactor, evacuate to -0.1 MPa, set the temperature in the reactor to 180°C, and set the temperature in the reactor at 160 rpm Perform high-temperature stirring reaction at a stirring speed, the reaction time is 55 minutes, then lower the temperature in the reactor to 120°C, add 12 parts of methylphenyl silicone oil, stir evenly at a stirring speed of 160 rpm, and then stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com