Manganese oxide catalyst as well as preparation method and application of manganese oxide catalyst

A manganese oxide and catalyst technology, applied in the field of manganese oxide catalyst and its preparation, can solve problems such as unfavorable large-scale promotion, high price of supported precious metal catalyst, unsatisfactory catalytic efficiency, etc., and achieve excellent CO2 generation selectivity, excellent Catalytic performance, better catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

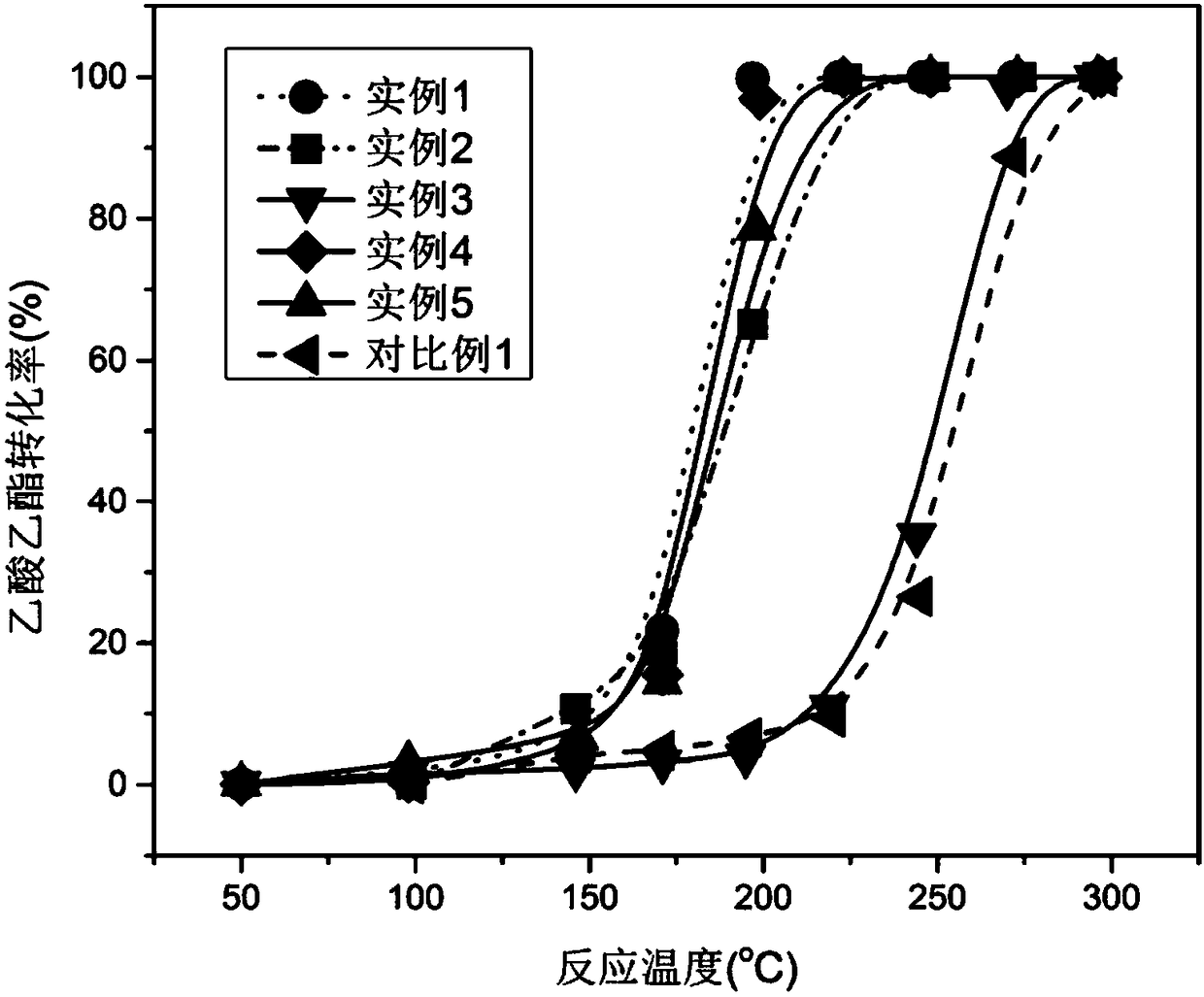

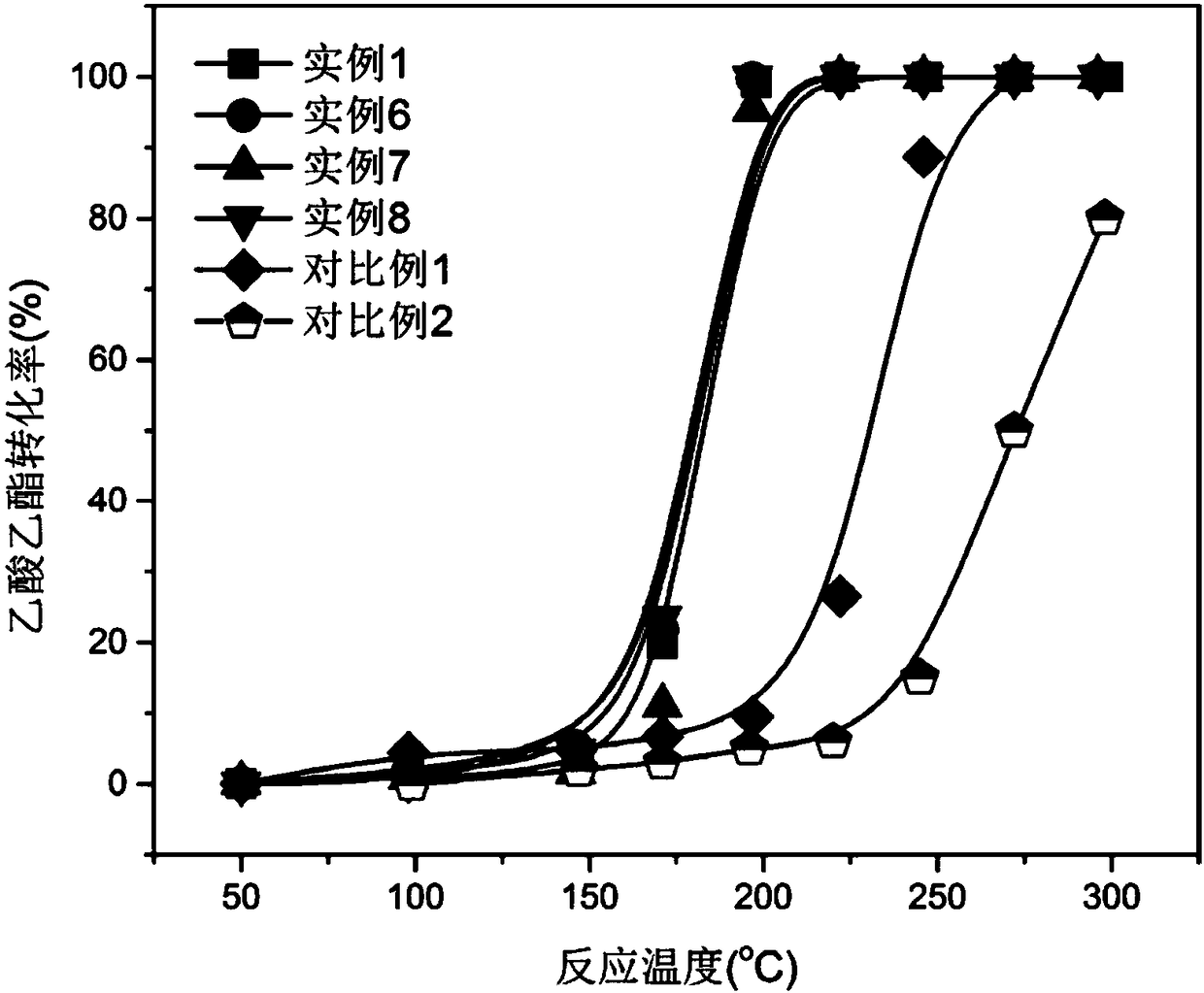

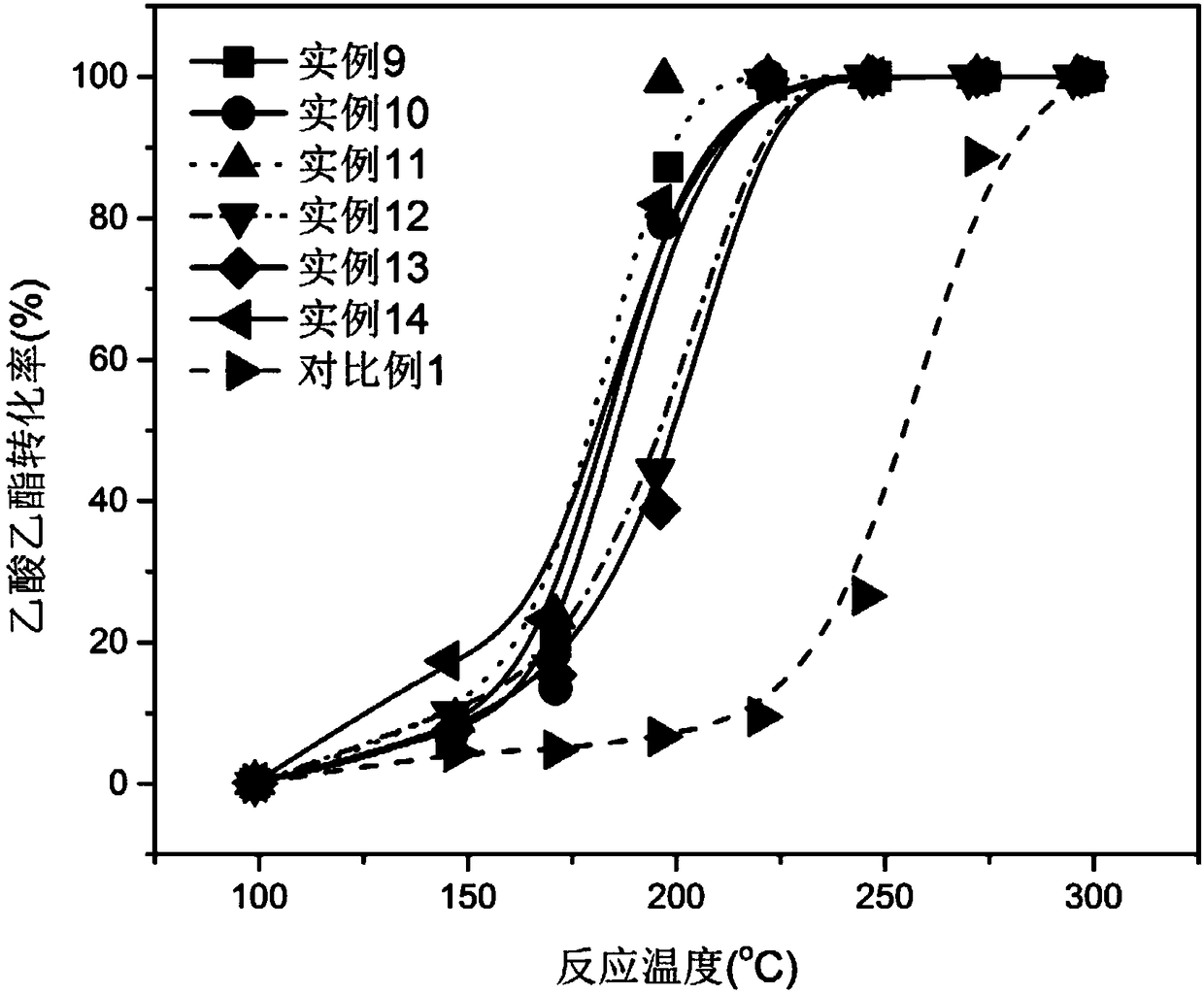

Embodiment 1

[0044] (1) Use potassium permanganate as the source of Mn, add 0.1 mol of Mn to 273 mL of deionized water to make a solution, add 63 g of excess urea as a precipitant, and stir continuously in a water bath at 90°C 24h, then suction filter the precipitate;

[0045] (2) After washing the precipitate obtained in step (1), it is placed in an oven for drying at 100° C. for 12 hours, and then calcined in a muffle furnace at 500° C. for 3 hours under an air atmosphere to obtain a powdered catalyst.

Embodiment 2

[0047] Compared with Example 1, except for replacing the manganese source potassium permanganate with manganese acetate, the other steps and conditions are exactly the same as those of Example 1.

Embodiment 3

[0049] Compared with Example 1, except for replacing the manganese source potassium permanganate with manganese sulfate, the other steps and conditions are exactly the same as those of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com