Emulsion with both resistance reduction and thickening properties in fracturing as well as rapid dissolution and preparation method thereof

An emulsion and performance technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as rapid dissolution, thickening, and drag reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

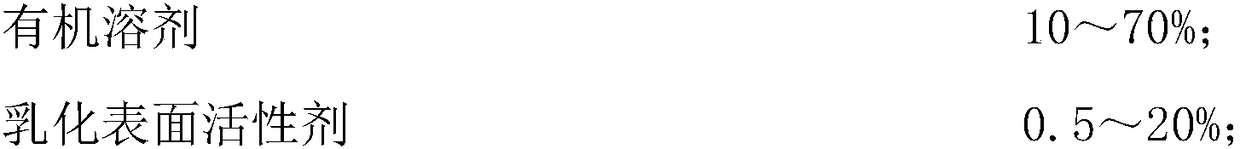

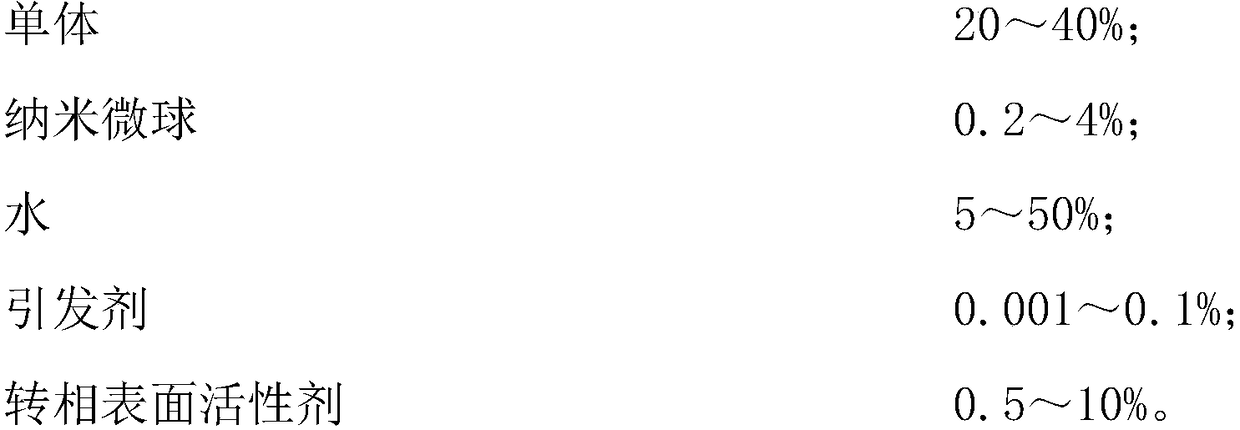

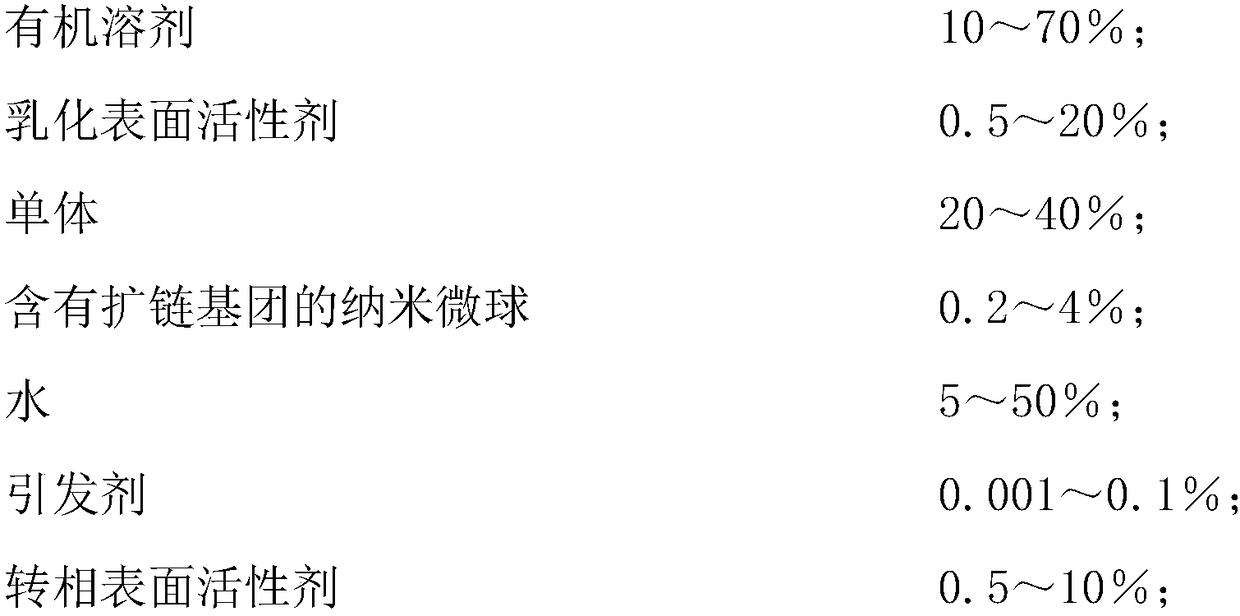

[0020] Specific implementation methods include:

[0021] (1) Preparation of the organic phase: add a certain amount of organic solvent in a polymerization kettle equipped with a stirring device, then continue to add a certain amount of emulsifying surfactant or a mixture of surfactants in the polymerization kettle, stir and mix evenly;

[0022] (2) For the preparation of the water phase, a certain amount of water is added to another liquid mixing kettle equipped with a stirring device, and then a certain amount of nano-polymer microspheres and monomers with chain extending groups are added in order, and the alkali is added. Adjust the pH value of the system, lower the temperature, and add the initiator;

[0023] (3) Mixing emulsification, introducing the prepared water phase into the polymerization tank containing the organic phase, stirring and mixing, and further emulsifying through the emulsification pump at the bottom of the tank to obtain a more stable emulsion;

[0024]...

Embodiment 1

[0028]Add 1000kg No. 7 white oil to a 3-party polymerization kettle equipped with a stirring device, then continue to add 150kg Span80 and 10kg Tween60 to the polymerization kettle, stir and mix evenly; add 1000kg to another 3-party liquid preparation kettle equipped with a stirring device Deionized water, then sequentially add 90kg of nano-polymer microspheres with chain-extending groups, 800kg of acrylamide, 80kg of acrylic acid, 20kg of AMPS, add sodium hydroxide to adjust the pH value of the system to 7.5±0.5, cool down to 15°C, Add 50 g of initiator ammonium persulfate; introduce the prepared water phase into the polymerization tank containing the organic phase through the tank bottom pump to stir and mix, and further emulsify through the emulsification pump at the bottom of the tank to obtain a more stable emulsion; Nitrogen gas was passed into the kettle, and the temperature was lowered to 20°C at the same time to carry out the polymerization reaction, and the temperatur...

Embodiment 2

[0030] Add 1000kg of kerosene to a 3-party polymerization kettle equipped with a stirring device, then continue to add 400kg Span60 and 50kgOP-7 into the polymerization kettle, and stir and mix evenly; Water, and then add 10kg of nano-polymer microspheres with chain-extending groups, 400kg of acrylamide, 200kg of acrylic acid, 100kg of AMPS in sequence, add sodium hydroxide to adjust the pH value of the system to 6.5±0.5, cool down to 15°C, add trigger Add sodium persulfate 100g; introduce the prepared water phase into the polymerization tank containing the organic phase through the bottom pump to stir and mix, and further emulsify through the emulsification pump at the bottom of the tank to obtain a more stable emulsion; Nitrogen was introduced, and the temperature was lowered to 20°C at the same time to carry out the polymerization reaction, and the temperature was controlled so that the final temperature of the system was lower than 100°C. The final polymerization time is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com