Gelling agent for acid fracturing operation and preparation method thereof

An acid fracturing, gelling agent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of reducing the efficiency of acid fracturing, shear instability, long dissolution time, etc. The effect of reducing the liquid preparation time, reducing the labor intensity of acid preparation, and improving the efficiency of acid preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

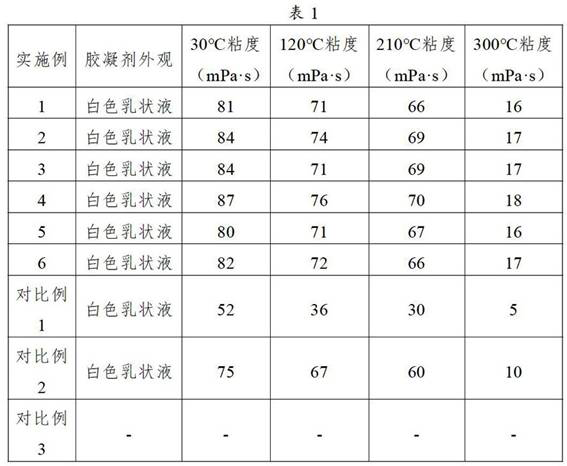

Examples

preparation example Construction

[0043] The invention provides a preparation method of a gelling agent for acidizing and fracturing operations, the preparation method comprising:

[0044] Step (1): carry out esterification reaction with methyl 2-benzyl acrylate and N,N-dimethylethanolamine, and then add chloromethane to carry out quaternization reaction to obtain functional cationic monomer;

[0045] Step (2): mixing the functional cationic monomer, cationic monomer, non-ionic monomer, sulfonic acid-based monomer, ammonium chloride and deionized water to obtain an aqueous reaction solution;

[0046] Step (3): mixing the oily solvent and the emulsifier to obtain an oil-phase reaction solution;

[0047] Step (4): adding the oil phase reaction solution to the water phase reaction solution, then adding an initiator to initiate a polymerization reaction, and adding a phase inversion agent after the reaction is completed to obtain a gelling agent for acid fracturing operations.

[0048] It should be noted that the...

Embodiment 1

[0094] Preparation of functional cationic monomers:

[0095] 1.1 mol of methyl 2-benzyl acrylate and 1 mol of N,N-dimethylethanolamine, as well as metal calcium and polymerization inhibitor (hydroquinone) were added to the reactor, and the temperature was raised to 110-120 °C while stirring and reacted 4h, the esterified product was obtained. The esterification product is naturally cooled to room temperature, and monochloromethane is added in batches under stirring conditions to control the temperature of the reaction process at 20~70 ° C. After the addition of monochloromethane, the temperature of the reactor no longer rises as a reaction. After the reaction is completed, the temperature is kept for 2 hours to obtain a functional cationic monomer; wherein, the molar ratio of the esterification product to chloromethane is 1:1.

[0096] Preparation of gelling agent for acid fracturing operation:

[0097] (1) 170 parts of functional cationic monomer, 10 parts of methacryloylox...

Embodiment 2

[0101] Preparation of functional cationic monomers:

[0102] 1.3 mol of methyl 2-benzyl acrylate and 1 mol of N,N-dimethylethanolamine, as well as metal calcium and polymerization inhibitor (hydroquinone) were added to the reactor, and the temperature was raised to 110-120 ° C while stirring and reacted 5h, the esterified product was obtained. The esterification product is naturally cooled to room temperature, and monochloromethane is added in batches under stirring conditions to control the temperature of the reaction process at 20~70 ° C. After the addition of monochloromethane, the temperature of the reactor no longer rises as a reaction. After the reaction is completed, the temperature is kept for 2 hours to obtain a functional cationic monomer; wherein, the molar ratio of the esterification product to monochloromethane is 1:1.1.

[0103] Preparation of gelling agent for acid fracturing operation:

[0104] (1) 220 parts of functional cationic monomers, 15 parts of acrylo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com