Cellulose antibacterial composite film made from pineapple leaves, and production method and application thereof

A cellulose film and pineapple leaf technology, applied in the field of film manufacturing, can solve the problems of easy deterioration and failure, short storage time of composite film, high preparation cost, and achieve the effects of low cytotoxicity, obvious effect and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

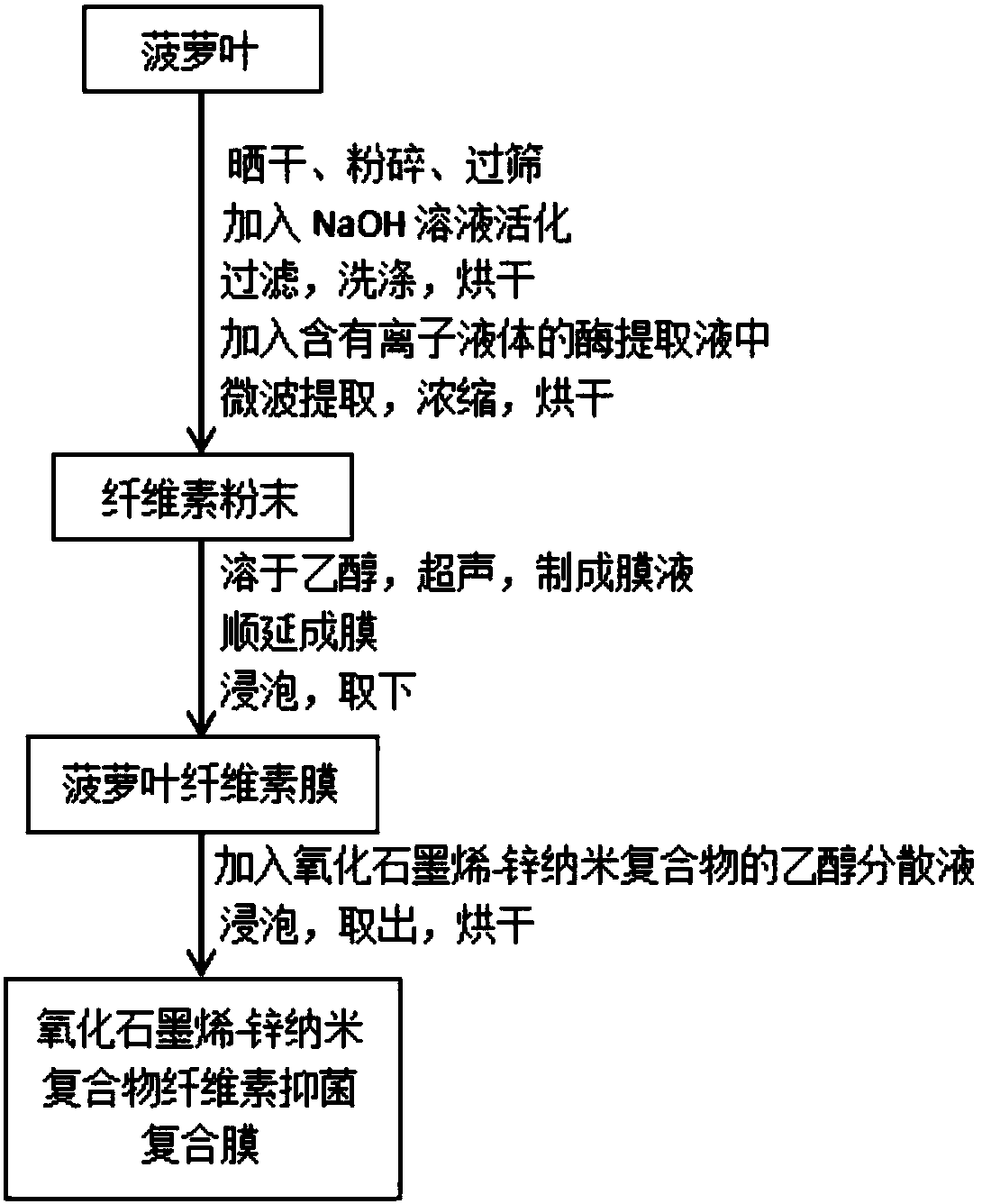

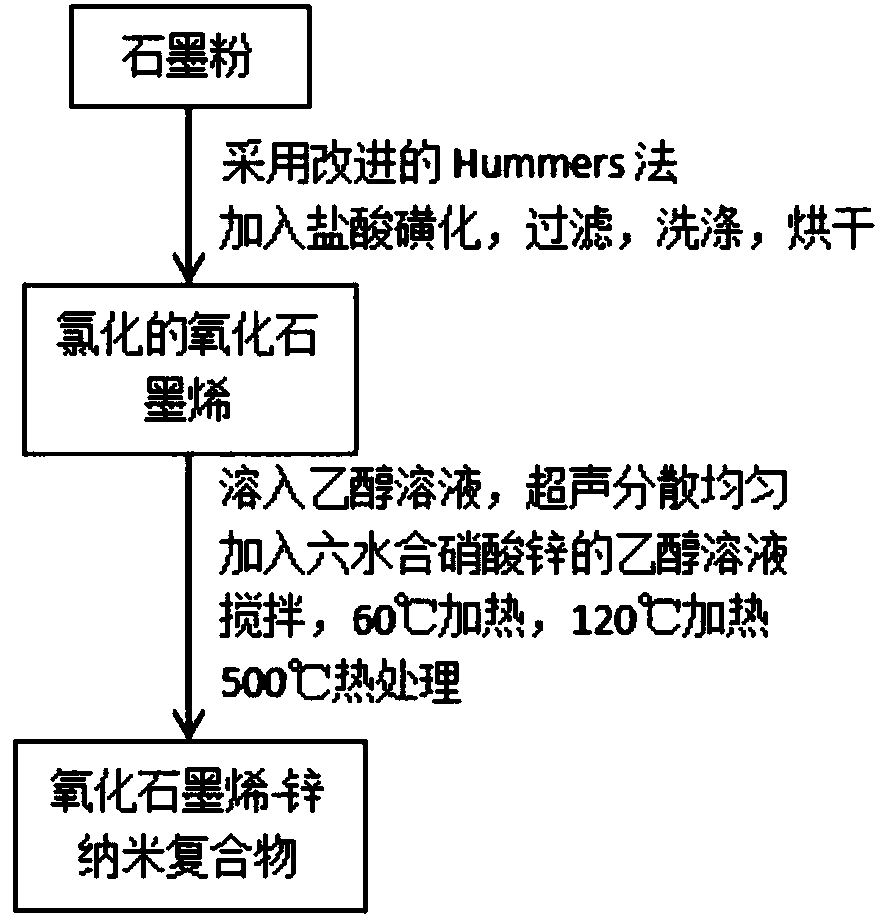

[0032] Embodiment 1 makes the preparation of cellulose antibacterial composite film with pineapple leaf

[0033] Follow the steps below:

[0034] (1) Extract cellulose from pineapple leaves: dry the pineapple leaves, crush them, and pass through a 100-mesh sieve to obtain pineapple leaf powder; add the pineapple leaf powder to 2mol / L NaOH solution, shake and react at 50°C for 3h to activate, filter, and use pure water After washing to neutrality, dry, add the solid to the mixed enzyme solution of 100U / g pectinase and 100U / g amylase containing 0.01mol / L pyridinium salt ionic liquid, microwave frequency is 2500MHz, microwave power is 500W, microwave After extracting for 2 hours, filter, concentrate in a water bath to 1 / 4 volume, and dry to obtain cellulose powder with a yield of 77%;

[0035] (2) Preparation of pineapple leaf cellulose film: Dissolve 100 g of cellulose powder prepared in step (1) in 500 mL of absolute ethanol, ultrasonicate at 700 W for 30 min to form a film li...

Embodiment 2

[0039] Embodiment 2 makes the preparation of cellulose antibacterial composite film with pineapple leaf

[0040] Follow the steps below:

[0041] (1) Extract cellulose from pineapple leaves: dry the pineapple leaves, crush them, and pass through a 100-mesh sieve to obtain pineapple leaf powder; add the pineapple leaf powder to 5mol / L NaOH solution, shake and react at 50°C for 3h to activate, filter, and use pure water After washing to neutrality, dry, add the solid to the mixed enzyme solution of 200U / g pectinase and 150U / g amylase containing 0.01mol / L imidazolium salt ionic liquid, microwave extraction for 2h and filter, microwave frequency 2500MHz, microwave With a power of 700W, concentrate in a water bath to 1 / 4 volume, and dry to obtain cellulose powder with a yield of 91%;

[0042](2) Preparation of pineapple leaf cellulose film: Dissolve 100 g of cellulose powder prepared in step (2) in 500 mL of absolute ethanol, ultrasonicate at 500 W for 30 min to form a film liquid...

Embodiment 3

[0046] Embodiment 3 makes the preparation of cellulose antibacterial composite film with pineapple leaf

[0047] Follow the steps below:

[0048] (4) Extract cellulose from pineapple leaves: dry the pineapple leaves, crush them, and pass through a 100-mesh sieve to obtain pineapple leaf powder; add the pineapple leaf powder to 5mol / L NaOH solution, shake and react at 50°C for 3h to activate, filter, and use pure water After washing to neutrality, dry, add the solid to the mixed enzyme solution of 200U / g pectinase and 150U / g amylase containing 0.01mol / L imidazolium salt ionic liquid, microwave extraction for 2h and then filter, microwave frequency 3000MHz, microwave With a power of 700W, concentrate in a water bath to 1 / 4 volume, and dry to obtain cellulose powder with a yield of 84%;

[0049] (5) Preparation of pineapple leaf cellulose film: Dissolve 100 g of cellulose powder prepared in step (2) in 1500 mL of absolute ethanol, ultrasonicate at 500 W for 30 min to form a film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com