Degradable high polymer material with patterned surface as well as preparation method and application thereof

A patterned surface and polymer material technology, applied in the field of degradable polymer materials and their preparation, can solve the problems of insufficient research on the degradation of biomaterials, and achieve strong controllability, good biocompatibility, and strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

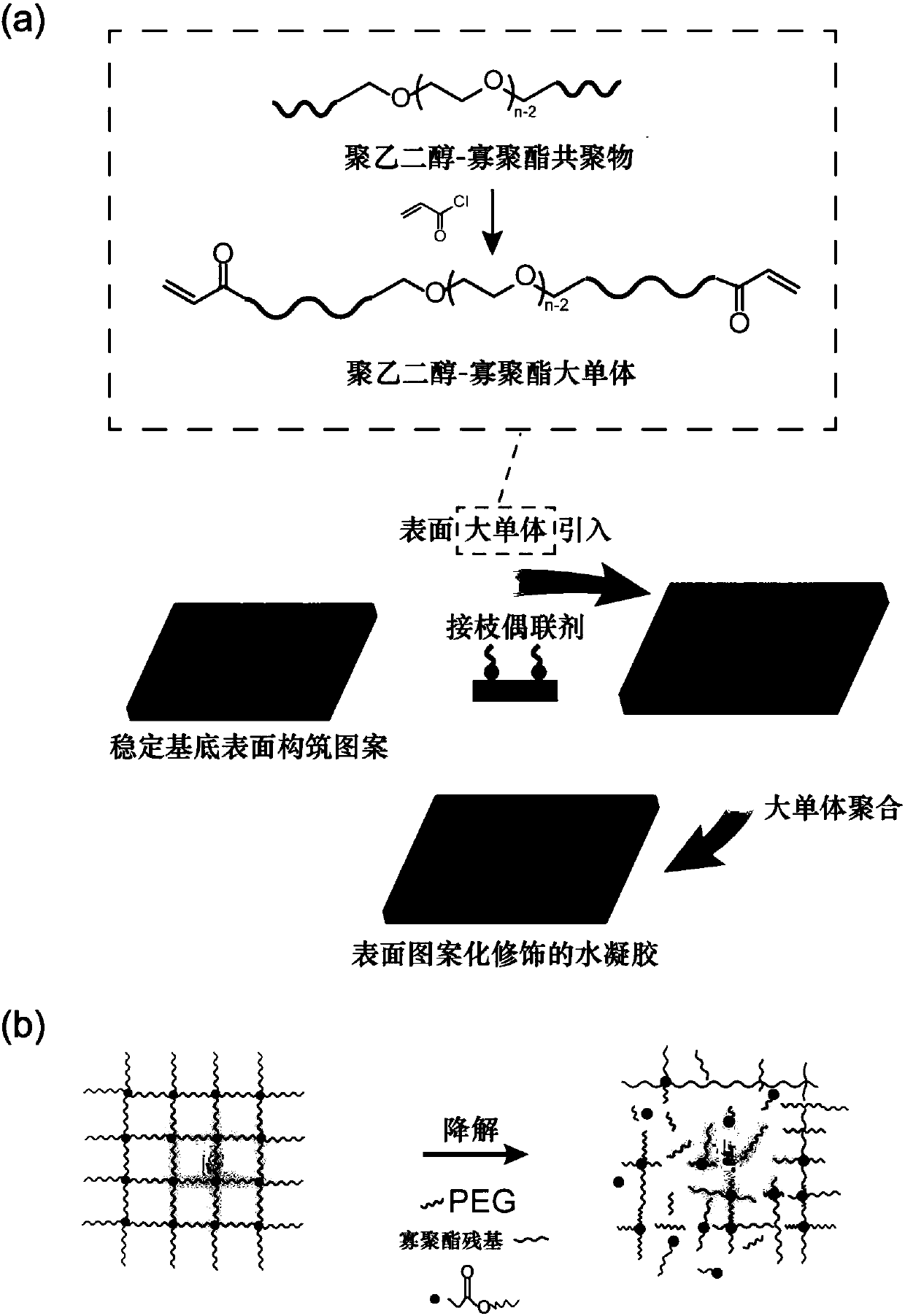

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Natural polymer derivative monomer synthesis

[0041] Take 50 g of hyaluronic acid (HA) with a molecular weight of 50 kDa and dissolve it in Milli-Q to prepare a 1 wt% solution, adjust the pH of the solution to 8 with 1 M sodium hydroxide solution, and add 50% to the solution system in a dropwise manner. equivalent of methacrylic anhydride, the system was reacted in an ice bath for 24 hours. After the reaction, use a dialysis membrane with a molecular weight cut-off of 5-8 kDa for dialysis. During the first 12 hours, the water is changed every hour, and the replacement time of the dialysis solution can be appropriately extended to 2 to 3 hours. The total dialysis time is 48 hours. Hour. After dialysis, the water was removed with a freeze dryer, and white powdery solid MeHA was taken out after 48 hours, and sealed and stored in a -20°C refrigerator.

Embodiment 2

[0043] Weigh the polyethylene glycol with dihydroxy ( M n = 2000) 50g (25 mmol), transferred into a three-necked reaction flask. The system was sealed, protected by argon gas, connected to a water-cooled pump for heat dissipation; the system was heated to 120 °C, and stirring was started at the same time, and vacuumed for 3 h to remove water. After the water removal was completed, the system was cooled to 80 °C, the argon ventilation was increased, and 14.4 g (100 mmol) of racemic lactide (DL-LA) and octanoic acid with a reactant ratio of 0.1 wt% were sequentially added to the three-necked flask. The stannous catalyst was used, and the system was heated to 140°C for the reaction. After 12 h of reaction, the reaction system was lowered to 120 °C, vacuumed for 2-3 h, and then the system was lowered to room temperature. Dilute the reaction product liquid with an appropriate amount of chloroform, and slowly transfer it into 1:10 volume ratio of glacial ether for sedimentation u...

Embodiment 3

[0045] Weigh the polyethylene glycol with dihydroxy ( M n = 2000) 50g (25 mmol), transferred into a three-necked reaction flask. The system was sealed, protected by argon gas, connected to a water-cooled pump for heat dissipation; the system was heated to 120 °C, and stirring was started at the same time, and vacuumed for 3 h to remove water. After the water removal was completed, the temperature of the system was lowered to 80 °C, the argon ventilation was increased, and 20.4 g (200 mmol) of trimethylene carbonate and a stannous octoate catalyst with a reactant ratio of 0.1 wt% were added to the three-necked flask in turn. The temperature of the system was raised to 140°C to carry out the reaction. After 12 h of reaction, the reaction system was lowered to 120 °C, vacuumed for 2-3 h, and then the system was lowered to room temperature. Dilute the reaction product liquid with an appropriate amount of chloroform, and slowly transfer it into 1:10 volume ratio of glacial ether...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com