Fluorescent powder material for light-emitting diode (LED) lighting and preparation method thereof

A technology for LED lighting and phosphors, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of high production cost, harsh reaction conditions, unsatisfactory process repeatability and product performance stability, etc., to reduce the reaction intensity, The effect of promoting sufficiency and preventing agglomeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

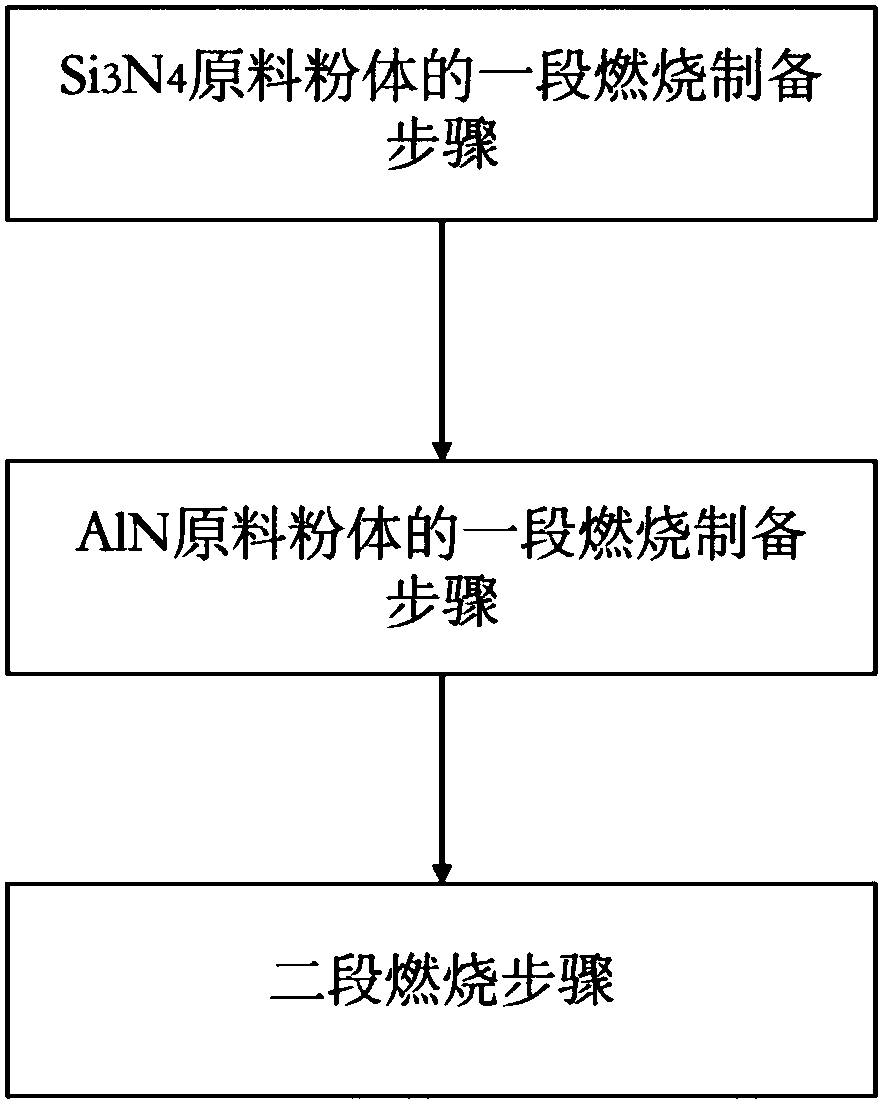

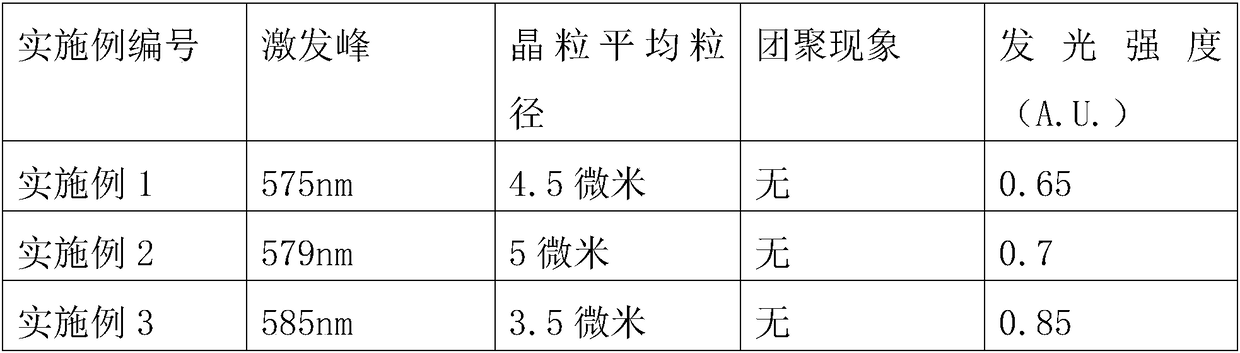

[0029] A preparation method of phosphor material for LED lighting, comprising the following steps:

[0030] (1) Si 3 N 4 One-stage combustion preparation step of raw material powder, taking silicon powder, Si 3 N 4 , NaN 3 Powder is used as raw material, wherein the mass percentage of silicon powder in the raw material is 62.5wt%, Si 3 N 4 The mass percentage of powder in the raw material is 13wt%, NaN 3 The mass percent of powder in raw material is 15.5wt%; Wherein, described silicon powder, NaN 3 、Si 3 N 4 The purity of the powder is greater than or equal to 98%, Si 3 N 4 α-Si3N in powder 4 accounted for all Si 3 N 4 The mass percentage of the powder is greater than or equal to 94.6wt%, and the rest is β-Si 3 N 4 And a small amount of free Si; the above raw materials are fully mixed and added to a vacuum high-pressure burner, and nitrogen with a purity greater than or equal to 99% is introduced after vacuuming, preferably with a nitrogen purity of 99.99%, and ...

Embodiment 2

[0036] A preparation method of phosphor material for LED lighting, comprising the following steps:

[0037] (1) Si 3 N 4 One-stage combustion preparation steps of raw material powder: take silicon powder, Si 3 N 4 , NaN 3 Powder is used as raw material, wherein the mass percentage of silicon powder in the raw material is 68.5wt%, Si 3 N 4 The mass percentage of powder in the raw material is 22wt%, NaN 3 The mass percent of powder in raw material is 9.5wt%; Wherein, described silicon powder, NaN 3 、Si 3 N 4 The purity of the powder is greater than or equal to 98%, Si 3 N 4 α-Si3N in powder 4 accounted for all Si 3 N 4 The mass percentage of the powder is greater than or equal to 94.6wt%; the above-mentioned raw materials are fully mixed and added to a vacuum high-pressure burner, and nitrogen with a purity greater than or equal to 99% is introduced after vacuuming, and the inflation pressure is greater than or equal to 2.0MPa and less than or equal to 2.5MPa. Ti p...

Embodiment 3

[0041] A preparation method of phosphor material for LED lighting, comprising the following steps:

[0042] (1) Si 3 N 4 One-stage combustion preparation steps of raw material powder: take silicon powder, Si 3 N 4 , NaN 3 Powder is used as raw material, wherein the mass percentage of silicon powder in the raw material is 65.5wt%, Si 3 N 4 The mass percentage of powder in the raw material is 17.5wt%, NaN 3 The mass percentage of the powder in the raw material is 17wt%. Among them, the silicon powder, NaN 3 、Si 3 N 4 The purity of the powder is greater than or equal to 98%, Si 3 N 4 α-Si3N in powder 4 accounted for all Si 3 N 4 The mass percentage of the powder is greater than or equal to 94.6wt%; the above-mentioned raw materials are fully mixed and added to a vacuum high-pressure burner, and nitrogen with a purity greater than or equal to 99% is introduced after vacuuming, and the inflation pressure is greater than or equal to 2.0MPa and less than or equal to 2.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com