Green and environment-friendly mine hydraulic support liquid

A hydraulic support, green and environmentally friendly technology, applied in the field of hydraulic support liquid, can solve the problems of non-compliance with freeze-thaw resistance, poor stability of hard water resistance, endangering personal health, etc., and achieve obvious economic and social benefits, freeze-thaw resistance performance Excellent effect with low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of green environment-friendly mine hydraulic support fluid, comprises the following components and the mass parts of each component are: 8 parts of mineral base oils, 4 parts of fatty acids, 5 parts of alkylamines, 2.5 parts of diethylene glycol monobutyl ether, emulsified 4 parts of agent, 0.5 part of benzotriazole, 8 parts of water-based rust inhibitor, 0.5 part of sodium hydroxide, 1 part of fungicide, 0.1 part of defoamer, and the rest of water. Preferably, the recommended concentration is 4-5% V / V.

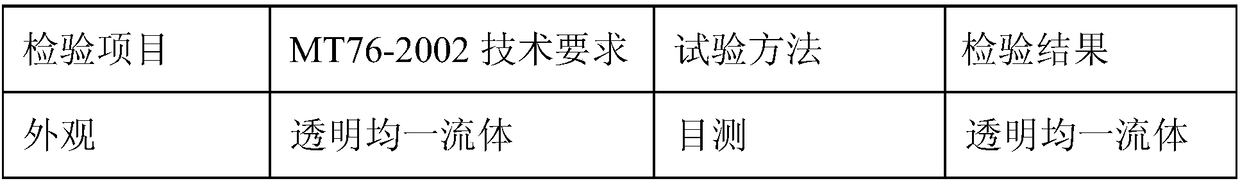

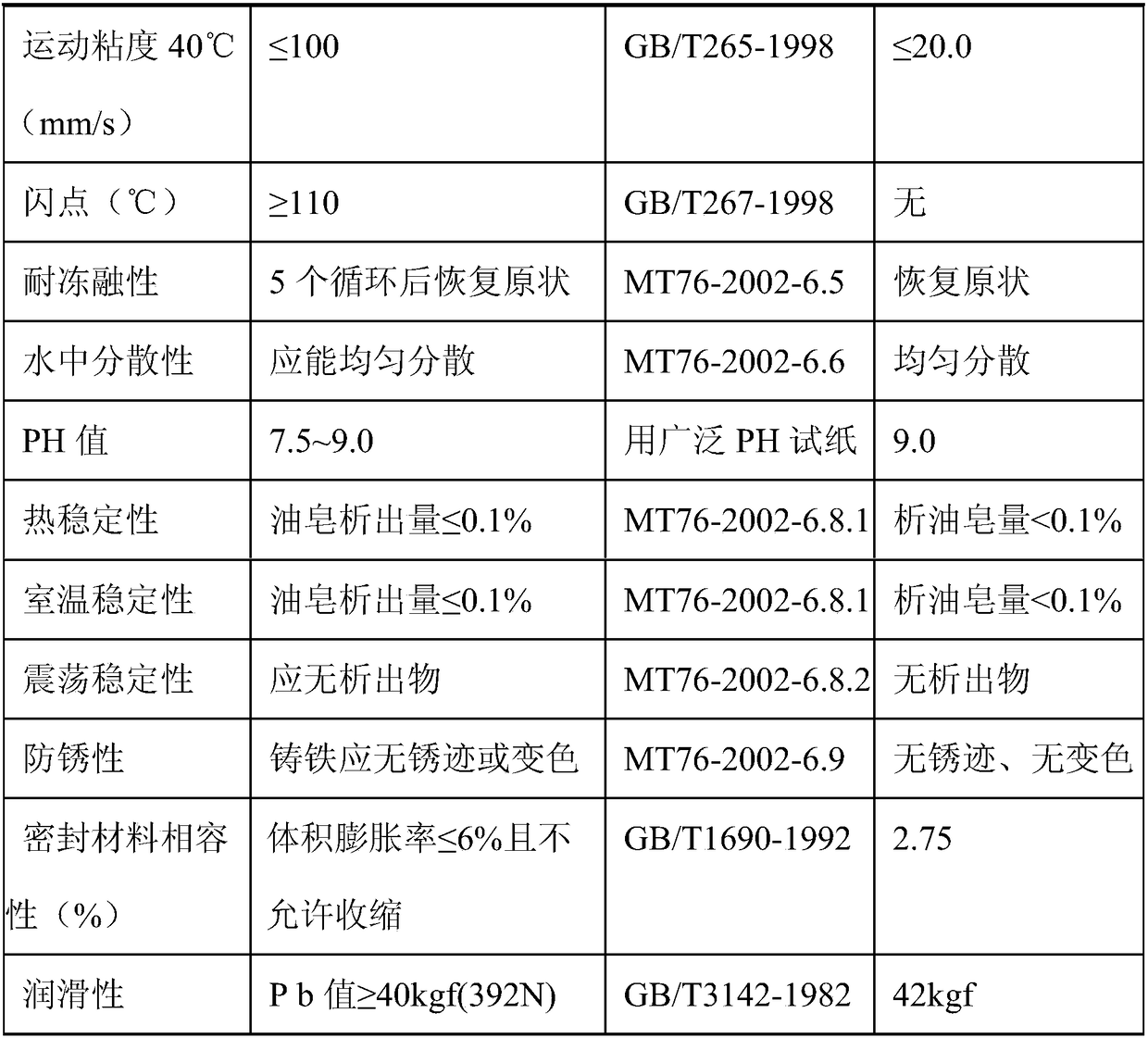

[0020] Table 1 Test results of Example 1 of a green environmental protection mine hydraulic support fluid

[0021]

[0022]

Embodiment 2

[0024] A kind of green environmental protection mine hydraulic support fluid, comprises the following components and the mass parts of each component are: mineral base oil 8 parts, fatty acid 4 parts, alkylamine 2 parts, diethylene glycol monobutyl ether 2.5 parts, emulsified 7 parts of anti-rust agent, 0.5 part of benzotriazole, 2.5 parts of tetrasodium EDTA, 2 parts of alcohol amine, 8 parts of water-based rust inhibitor, 0.5 part of sodium hydroxide, 1 part of fungicide, 0.01 part of defoamer, and the remaining water quantity. Preferably, the recommended concentration is 4-5% V / V.

Embodiment 3

[0026] A kind of green environment-friendly mine hydraulic support liquid, comprises the following components and the mass parts of each component are: 8 parts of mineral base oils, 7 parts of fatty acids, 5 parts of alkylamines, 2.5 parts of diethylene glycol monobutyl ether, emulsified 4 parts of antirust agent, 0.3 part of benzotriazole, 1 part of tetrasodium EDTA, 5 parts of alcohol amine, 8 parts of water-based antirust agent, 0.8 part of sodium hydroxide, 1 part of fungicide, 0.1 part of defoamer, water quantity. Preferably, the recommended concentration is 4-5% V / V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com