Method for synthesizing rebaudioside-A through high-density fermentation

A high-density fermentation and rebaudioside technology, applied in the field of bioengineering, can solve the problems of complex intracellular substances, unfavorable extraction and purification, and limited intracellular accumulation, and achieve high conversion rate, increased efficiency, and small cell damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

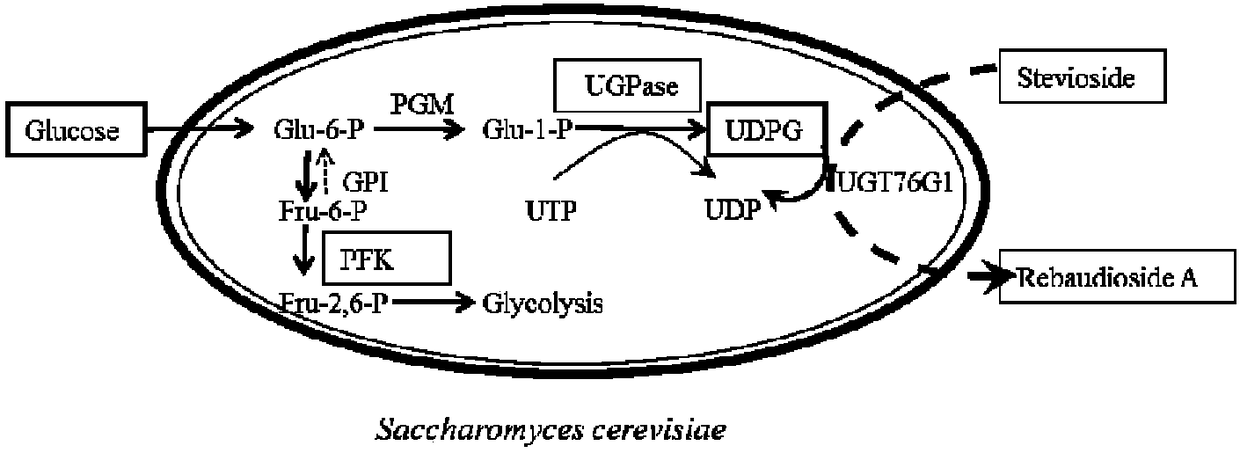

Method used

Image

Examples

Embodiment 1

[0059] Example 1: Knockout of a gene encoding a cell wall synthetase

[0060] Look up the sequences of genes FKS1, GSC2, OCH1, MNN9, DSE2, CHS3, and CRH1 in the NCBI database, and design primers with their gene homology arm sequences to amplify the above genes by PCR. The reaction system is:

[0061] ddH2O: 19 μL

[0062] P3: 2 μL

[0063] P4: 2 μL

[0064] Template: 2 μL

[0065] 2×Phanta Master Mix: 25μL

[0066] Total volume: 50 μL

[0067] Among them, denaturation, retreat temperature and corresponding time are calculated according to the primers.

[0068] Table 1 Primer sequences

[0069]

[0070]

Embodiment 2

[0071] Example 2: Construction of recombinant bacteria YLY01(△fks1), YLY01(△gsc2), YLY01(△och1), YLY01(△mnn9), YLY01(△dse2), YLY01(△chs2), YLY01(△crh1)

[0072] The NEO gene in Example 1 was separated and recovered by agarose gel, and the purified fragment was transformed into Saccharomyces cerevisiae competent YPH499 (Invitrogen) by chemical transformation method. Spread the yeast transformation solution on YPDA (containing a certain concentration of G418 resistance) medium plate (YPDA: yeast extract 10g / L, peptone 20g / L, glucose 20g / L, adenine 0.75g / L), and grow at 30°C Until a single colony grows, the positive clones are verified by colony PCR. The positive clones were named YLY01(△fks1), YLY01(△gsc2), YLY01(△och1), YLY01(△mnn9), YLY01(△dse2), YLY01(△chs2), YLY01(△crh1) and preserved kind.

Embodiment 3

[0073] Example 3 Effects of promoters on the expression levels of genes UGT76G1 and UGPase

[0074] Screen the promoter to increase the transcription level of the target gene. In this example, the following promoters are selected, TEF1, PGK1, HXT7, GPM1, CDC5, FBA1, ENO2, GAL10, and ALA1. The selected promoters were connected to the target gene by homologous recombination, and the enzyme activities of UGT76G1 and UGPase under the regulation of different promoters were compared.

[0075] The successfully constructed engineered bacteria were transferred to 100mL YPDA liquid medium and grown on a shaker at 30°C for 24h. The above-mentioned bacteria sludge was collected by centrifugation, and the bacteria sludge was washed three times with 100 mM, pH 8.0 phosphate buffer. The cells were disrupted with an ultrasonic disruptor for 20 min, the disrupted solution was centrifuged at 12000 rpm for 30 min, and the supernatant enzyme solution was collected.

[0076] The enzyme activity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com