Preparation method of tungsten sulfide doped conductive polythiophene counter electrode used for dye-sensitized solar cell

A technology for solar cells and dye sensitization, which is applied in the field of preparation of conductive polythiophene counter electrodes, can solve the problems of high cost and complicated polymer film process, and achieve the effects of low cost, simple device and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Preparation of photoanode

[0038] The photoanode (the total thickness of the titanium dioxide film is 16 μm, including a 20 nm granular titanium dioxide layer with a thickness of 12 μm, and a 200 nm granular titanium dioxide layer with a thickness of 4 μm) was prepared on the FTO glass by screen printing technology, and the prepared The photoanode was immersed in an ethanol solution of N719 dye at a concentration of 0.3 mM, and placed in the dark for 24 h, so that the dye was sensitized and adsorbed on the titanium dioxide photoanode. After the sensitization treatment is completed, take it out and clean it with absolute ethanol, and let it dry naturally before use.

[0039] Electrolyte

[0040] The electrolyte composition is 0.1 M LiI, 0.05 M I 2 , 0.3 M DMPII (1,2-dimethyl-3-propylimidazolium iodide) and 0.5 M tert-butylpyridine in acetonitrile.

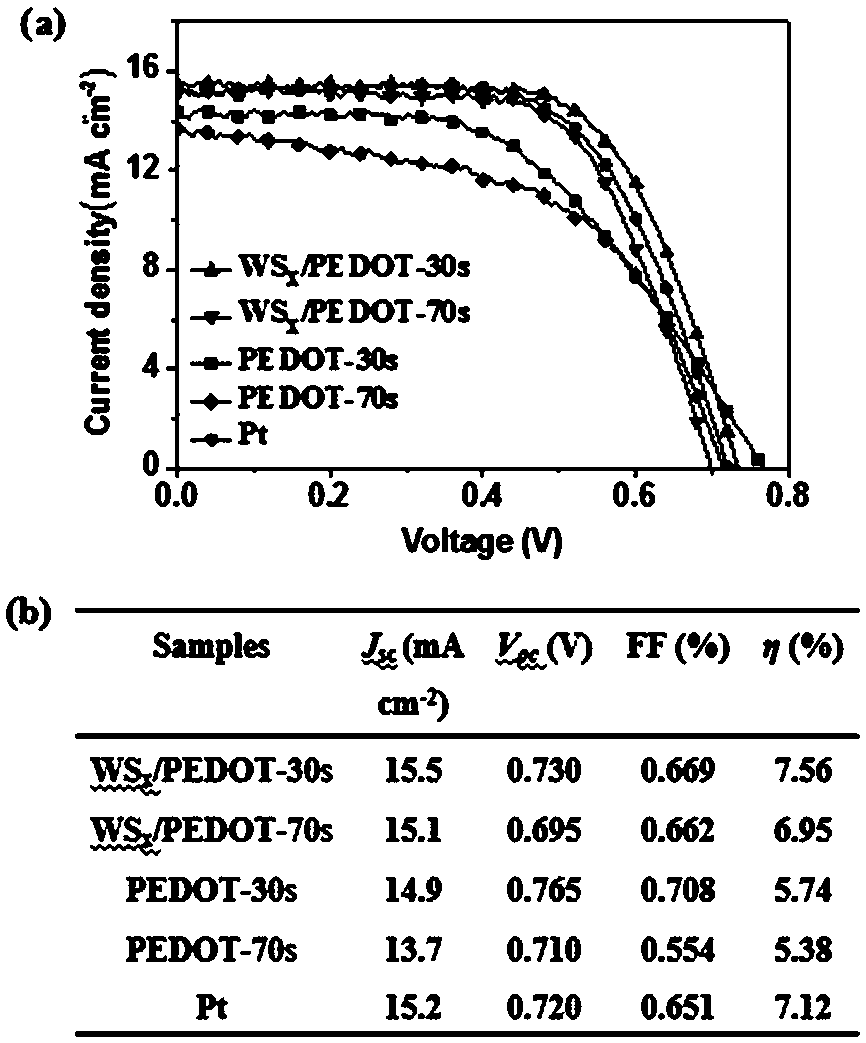

Embodiment 1

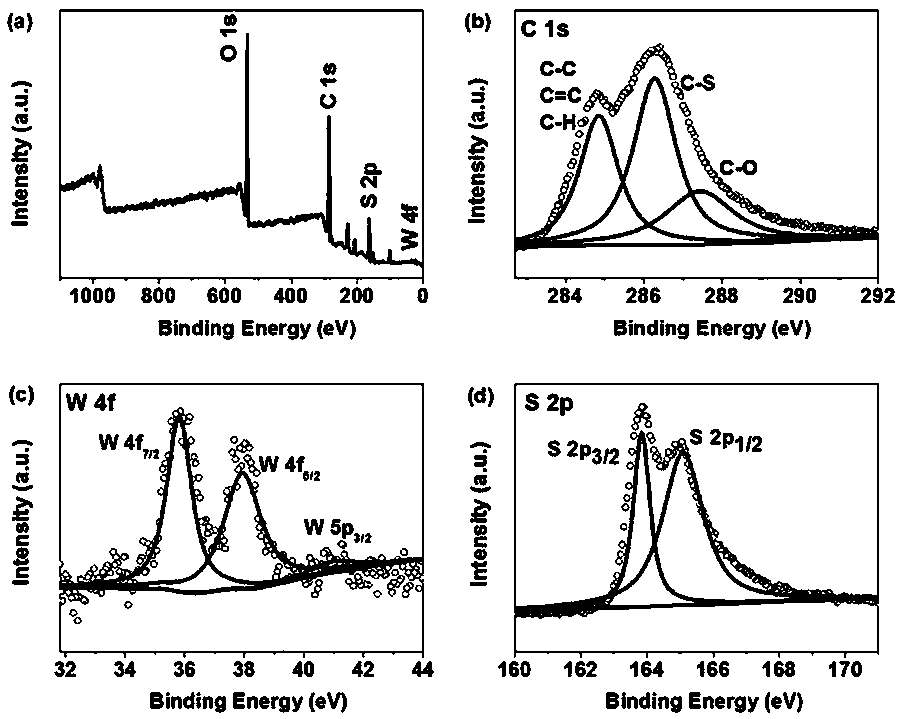

[0042] (1) Install the cleaned FTO conductive glass on the working electrode, and the conductive surface is in close contact with the platinum sheet. Put 20 mL of 0.1 M lithium perchlorate / acetonitrile dissolved in 0.1 mmol ammonium tetrathiotungstate and 0.94 mmol EDOT In the solution, immerse about 2 / 3, insert the platinum auxiliary electrode and the silver-silver chloride reference electrode to form a three-electrode system, connect the circuit, and prepare for deposition.

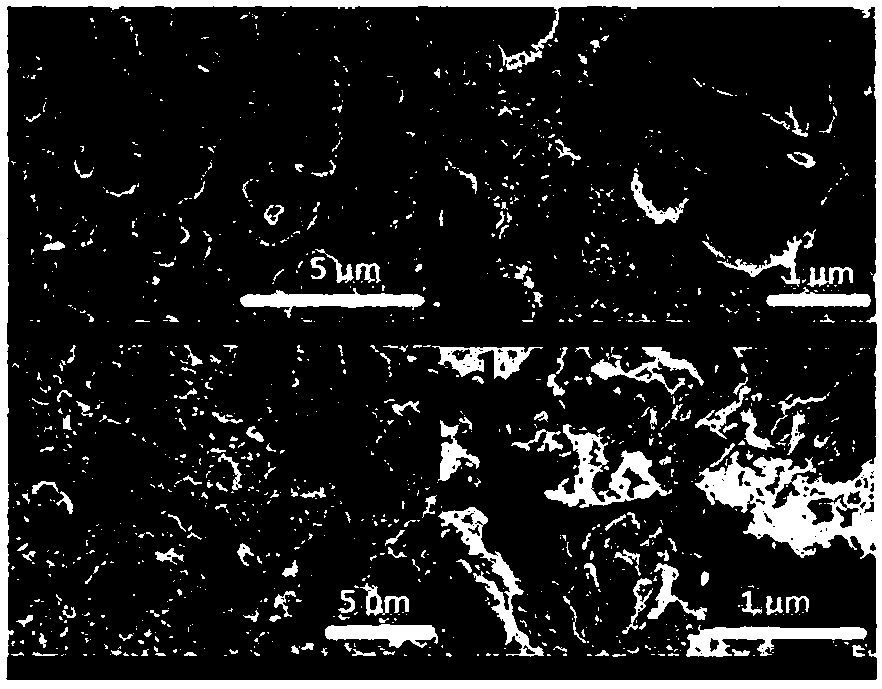

[0043] (2) A conductive polymer film doped with tungsten sulfide was prepared on the conductive surface of FTO glass by electrodeposition.

[0044] (3) The technical parameters set by the deposition method are as follows: use adhesive tape to set the working area of the working electrode to 0.385cm 2 , set the potential applied to the working electrode as 1.5 V, the deposition time as 30 s, and other default values.

[0045] (4) After the deposition, the FTO glass is taken out to obtain a conductive ...

Embodiment 2

[0047] (1) Install the cleaned FTO conductive glass on the working electrode, and the conductive surface is in close contact with the platinum sheet. Put 20 mL of 0.1 M lithium perchlorate / acetonitrile dissolved in 0.1 mmol ammonium tetrathiotungstate and 0.94 mmol EDOT In the solution, immerse about 2 / 3, insert the platinum auxiliary electrode and the silver-silver chloride reference electrode to form a three-electrode system, connect the circuit, and prepare for deposition.

[0048] (2) A conductive polymer film doped with tungsten sulfide was prepared on the conductive surface of FTO glass by electrodeposition.

[0049] (3) The technical parameters set by the deposition method are as follows: use adhesive tape to set the working area of the working electrode to 0.385cm 2 , set the potential applied to the working electrode as 1.5 V, the deposition time as 70 s, and other default values.

[0050] (4) After the deposition, the FTO glass is taken out to obtain a conductive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com