Intelligent processing terminal cooling device

A technology of intelligent processing and cooling device, applied in cooling/ventilation/heating renovation, coating, electrical equipment structural parts, etc., can solve the problems of reduced life, damage, high energy consumption, etc., to achieve good compatibility of base materials, Enhance mechanical strength and increase the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

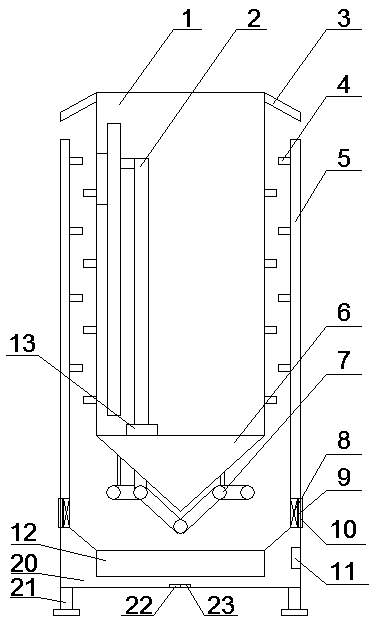

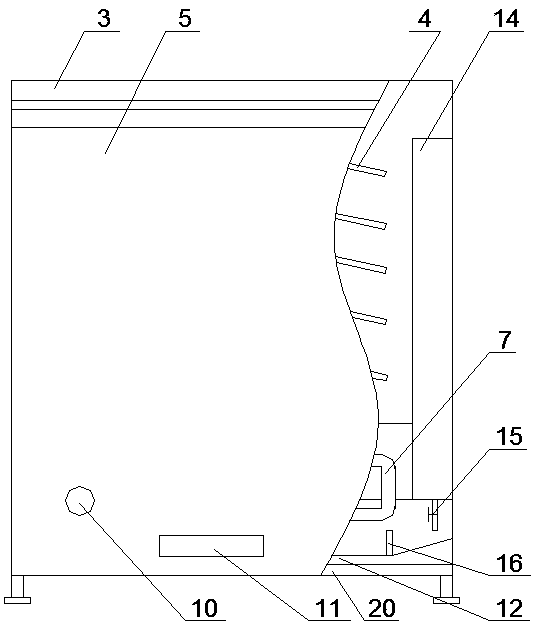

[0045] An intelligent processing terminal cooling device, comprising a box body 1, an internal circulation mechanism arranged inside the box body 1 to cooperate with heating elements, an outer circulation mechanism arranged at the lower part of the box body, and an outer circulation mechanism arranged in the outer circulation mechanism The lower coolant generator, the return mechanism arranged on the side of the box, and the controller 11 arranged on the side wall of the box and matched with the coolant generator and the internal circulation mechanism;

[0046] The internal circulation mechanism includes an internal circulation pipe 7 arranged inside the box and in contact with the heating element for heat conduction, and the internal circulation pipe 7 is provided with a micro oil pump 13 connected to the controller 11;

[0047] The external circulation mechanism includes an external serpentine pipe 7 arranged at the lower part of the box body 1 and provided through a bracket ...

Embodiment 2

[0063] It differs from Embodiment 1 in that:

[0064] The bottom of the box body 1 is a conical bottom surface 6a.

[0065] The condensation plate 4 is a circular arc plate 4a arranged on the return plate 5 or the peripheral wall of the box body 1 .

[0066] The box 1 is a cylinder.

[0067] The bottom of the base 20 is provided with a plurality of telescopic rods 21 for support, and a balance detection module that cooperates with the telescopic rods 21 and is arranged at the center of the bottom of the base 20;

[0068] Described balance detection module comprises MEMS gyroscope 22 and MEMS accelerometer 23;

[0069] The telescopic rod 21 is an electric telescopic rod, and the end of the electric telescopic rod is provided with feet.

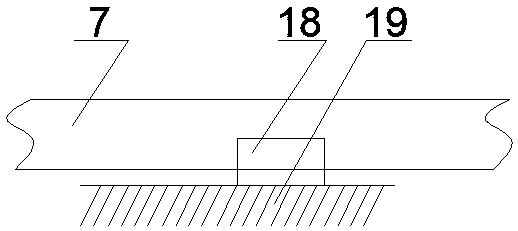

[0070] The surface of the outer serpentine tube 7 is provided with fins for heat dissipation.

[0071] A solenoid valve 15 is provided at the outlet of the lower part of the water tank 1, and the solenoid valve 15 is connected to the water ...

Embodiment 3

[0078] It differs from Embodiment 2 in that the fluorescent paint is mainly made of the following raw materials in parts by weight:

[0079] 34 parts of acrylic emulsion, 26 parts of alkyd resin, 5 parts of fluorescent powder, 3 parts of glass beads, 1.6 parts of glass fiber, 10 parts of titanium dioxide, 7 parts of ultrafine barium sulfate, 9 parts of ethanol, 8 parts of water and 1.4 parts of dispersant share.

[0080] Wherein the preparation method of fluorescent powder comprises the following steps: dissolving strontium chloride and aluminum chloride in a sufficient volume fraction of 60% ethanol solution, then adding silicon nitride and europium trioxide to disperse evenly to form a suspension, and then using Ammonia water adjusts the pH value to 8-9, obtains a precipitate after vacuum filtration, vacuum-dries at 70°C for 3 hours, and calcines at 1050°C for 2 hours under a CO reducing atmosphere to obtain fluorescent powder. The strontium chloride, aluminum chloride, nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com