Hexamethylene diamine synthesis reaction system

A synthesis reaction and hexamethylenediamine technology, applied in the preparation of amino compounds, organic compounds, chemical instruments and methods, etc., can solve the problems of poor material contact, inconvenient maintenance, low reaction efficiency, etc., to achieve full contact Good, rapid response, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

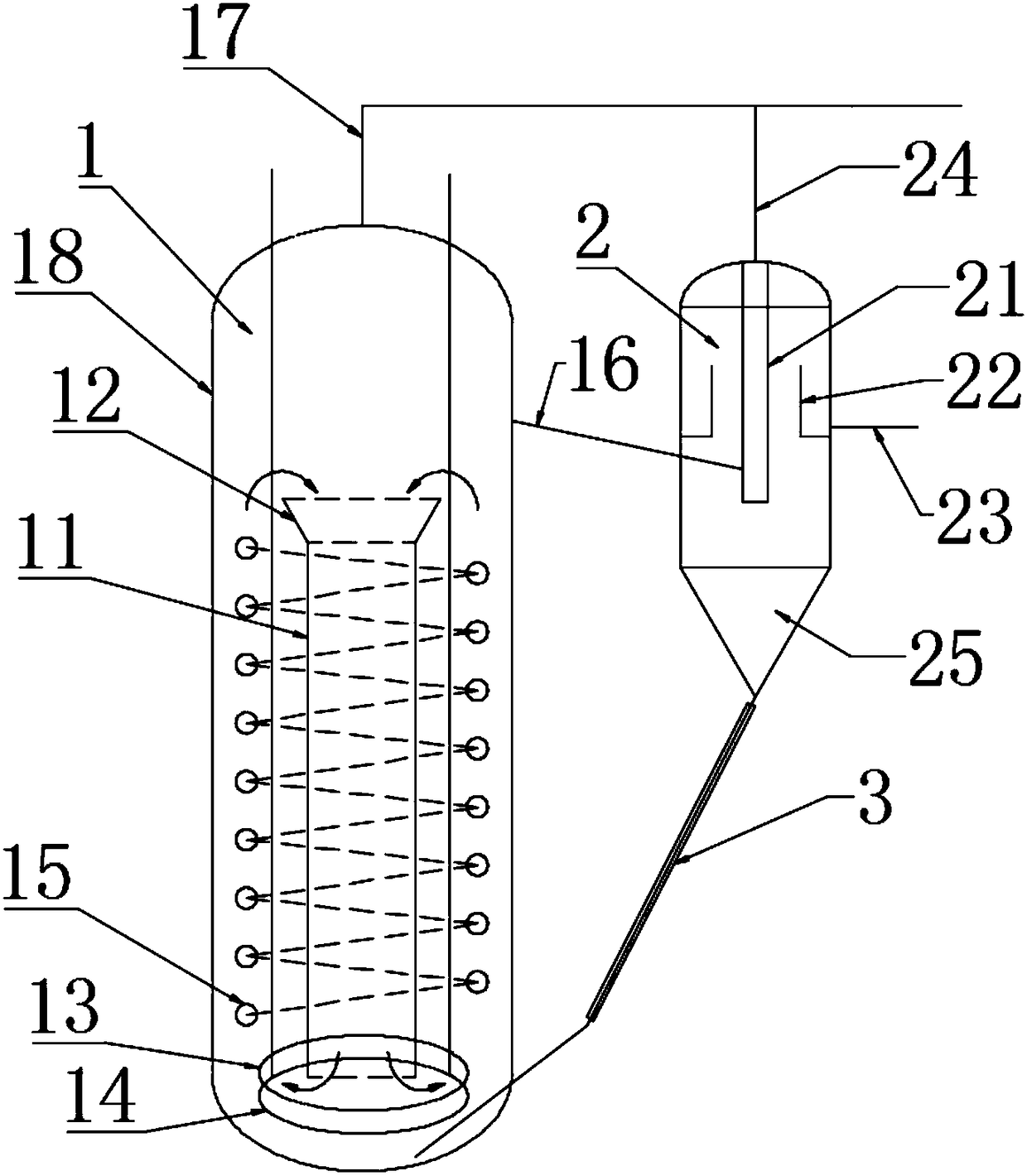

[0036] A kind of hexamethylenediamine synthetic reaction system, such as figure 1 As shown, it consists of a hexamethylenediamine loop reactor 1, a catalyst settling tank 2, and a catalyst circulation pipe 3.

[0037]The hexamethylenediamine loop reactor 1 consists of a reactor tower body 18, a draft tube 11, a bell mouth 12, a hydrogen distributor 13, adiponitrile distributor 14, a heat exchange coil 15, a material outlet 16, and a hydrogen outlet 17. .

[0038] The reactor 1 is in the shape of a tower with an aspect ratio of 5-50, preferably 10-30.

[0039] The guide tube 11 has a tower shape with an aspect ratio of 10-50, preferably 20-40, and its upper part is connected with the bell mouth 12 . One or more can be set. The reactor tower body 18 and part of the area are reaction area and heat transfer area, vapor-liquid separation area, liquid circulation area

[0040] The bell mouth 12 is connected with the guide tube 11, its lower part has the same diameter as the guid...

Embodiment 2

[0054] A kind of hexamethylenediamine synthetic reaction system, such as figure 1 Shown, comprise hexamethylenediamine loop reactor 1, catalyst settling tank 2, catalyst circulation pipe 3, wherein one end of catalyst circulation pipe 3 links to each other with the bottom of catalyst settling tank 2, and the other end links to each other with diamine loop reactor 1; The hexamethylenediamine loop reactor 1 comprises a draft tube 11, a bell mouth 12, a hydrogen distributor 13, an adiponitrile distributor 14, a heat exchange coil 15, a discharge port 16, a hydrogen outlet 17, and a reactor tower body 18 , wherein the guide tube 11 is vertically arranged inside the reactor tower body 18, and the upper end of the guide tube 11 is connected with a bell mouth 12, and the wide mouth of the bell mouth 12 faces upwards, and inside the reactor tower body 18 is also A hydrogen distributor 13 and an adiponitrile distributor 14 are respectively provided with, the hydrogen distributor 13 is ...

Embodiment 3

[0057] A kind of hexamethylenediamine synthetic reaction system, such as figure 1 Shown, comprise hexamethylenediamine loop reactor 1, catalyst settling tank 2, catalyst circulation pipe 3, wherein one end of catalyst circulation pipe 3 links to each other with the bottom of catalyst settling tank 2, and the other end links to each other with diamine loop reactor 1; The hexamethylenediamine loop reactor 1 comprises a draft tube 11, a bell mouth 12, a hydrogen distributor 13, an adiponitrile distributor 14, a heat exchange coil 15, a discharge port 16, a hydrogen outlet 17, and a reactor tower body 18 , wherein the guide tube 11 is vertically arranged inside the reactor tower body 18, and the upper end of the guide tube 11 is connected with a bell mouth 12, and the wide mouth of the bell mouth 12 faces upwards, and inside the reactor tower body 18 is also A hydrogen distributor 13 and an adiponitrile distributor 14 are respectively provided with, the hydrogen distributor 13 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com