Solid phase microextraction head for enriched perfluoro compound and preparation method thereof

A solid-phase microextraction head and perfluorinated compound technology, which is applied in the field of food analysis, can solve the problems of lack of special extraction heads for perfluorinated compounds, and achieve the effects of high mechanical strength, improved extraction efficiency, enhanced stability and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

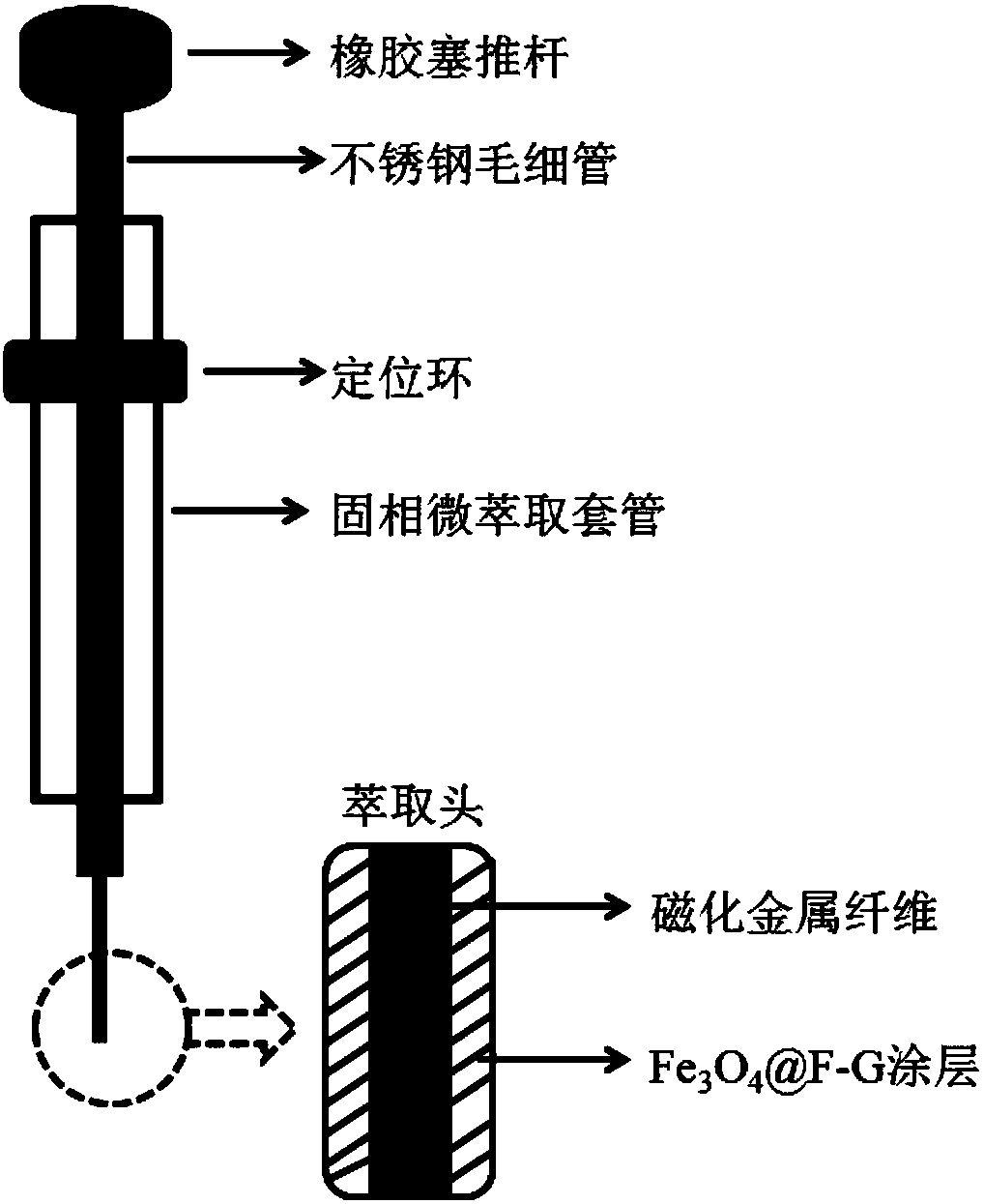

[0031] A solid-phase microextraction head for enriching perfluorinated compounds, the preparation method of which is as follows:

[0032] 1) Take an iron wire with a diameter of 0.3mm, roughen its surface with fine sandpaper, and place it with a permanent magnet for several days until it becomes magnetic, then use 0.1M sodium hydroxide, 0.1M hydrochloric acid, methanol , acetone and ultrapure water for 10 minutes to remove surface oxides and impurities, and then dry in a vacuum oven.

[0033] 2) Preparation of fluorinated graphene (F-G):

[0034] Weigh 100 mg of graphene oxide into a 200 mL beaker, add 100 mL of ultrapure water, and sonicate for 30 minutes to obtain a uniform graphene oxide dispersion. Add the dispersion into a polytetrafluoroethylene-lined hydrothermal kettle, and add 60mL of hydrofluoric acid, tighten the hydrothermal kettle to make it airtight, then place it in an oven and keep it warm at 180°C 24h. After the reaction was completed, it was allowed to coo...

Embodiment 2

[0040] The metal carrier used in the experiment of this example is nickel wire, the diameter of which is 0.4 mm. The surface of the nickel wire is polished with fine sandpaper to roughen it, and then it is placed together with a permanent magnet for several days until it becomes magnetic. Wash with ultrapure water for 10 minutes to remove surface impurities. The cleaned magnetized nickel wire was vertically immersed in the dispersion for 5 minutes, then lifted vertically at a constant speed, and the pulling process was repeated until the coating thickness reached about 20 μm. The metal wire was subjected to aging treatment at 150°C for 1 h in a high-purity nitrogen atmosphere.

[0041] Other steps and preparation conditions are all identical with embodiment 1.

Embodiment 3

[0043]The iron wire of the metal carrier in the experiment of this embodiment, the diameter of the iron wire is 0.2mm, and its surface is roughened with fine sandpaper, and then placed together with a permanent magnet for several days until it is magnetic, and then washed with 0.1M sodium hydroxide , 0.1M hydrochloric acid, methanol, acetone and ultra-pure water for 10 minutes to remove surface oxides and impurities, immerse the cleaned magnetized iron wire vertically in the dispersion for 5 minutes, then lift it vertically at a constant speed, and repeat the pulling process until The coating thickness reaches about 100 μm. The metal wire was subjected to aging treatment at 200°C for 1.5h in a high-purity nitrogen atmosphere.

[0044] Other steps and preparation conditions are all identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com