A kind of desizing agent and preparation method thereof

A desizing agent and formula technology, applied in the field of textile printing and dyeing auxiliaries, can solve the problems of not paying attention to the wool effect, hand feeling and single performance of the fabric.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of desizing agent of embodiment 1

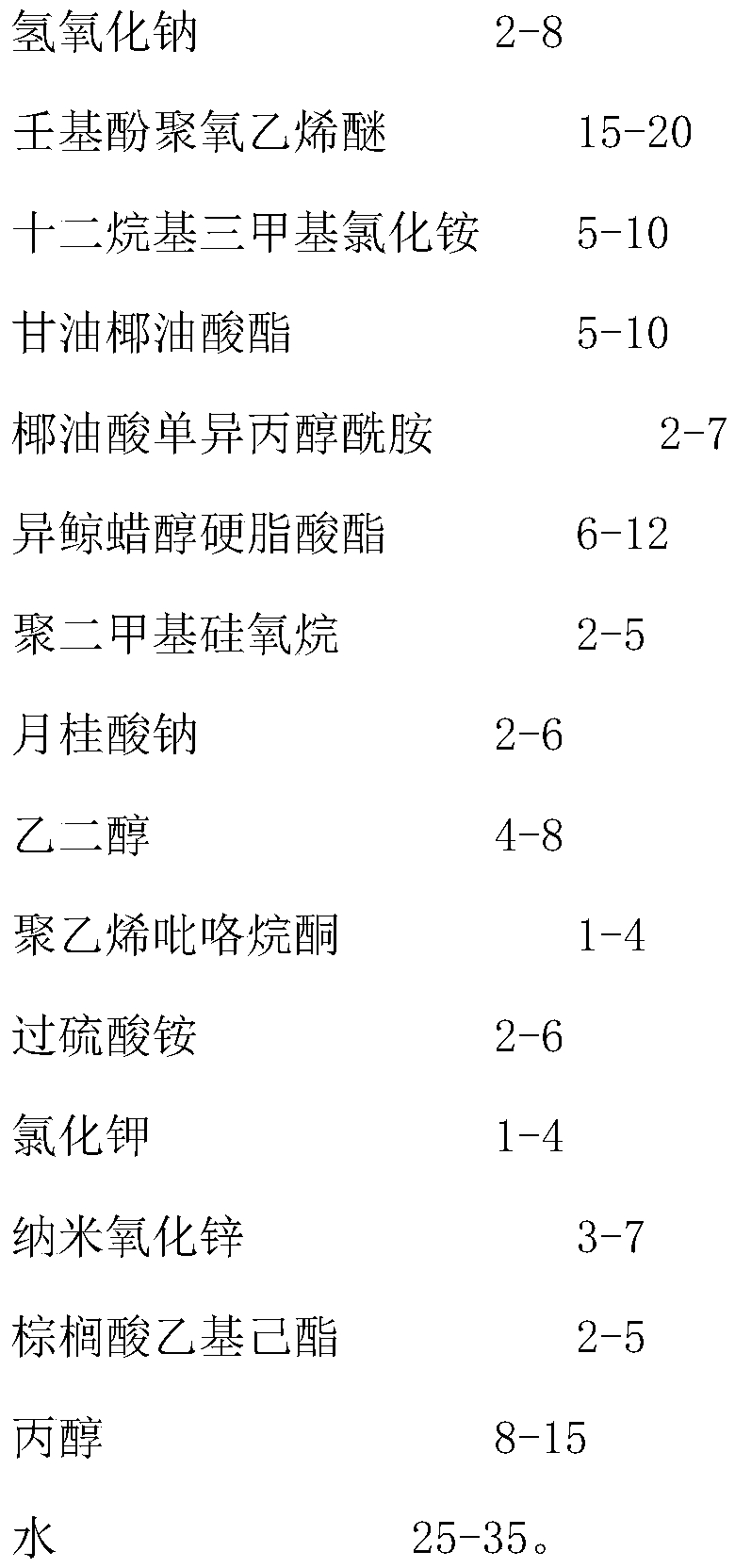

[0034] Formula, comprises by weight:

[0035]

[0036] Wherein the average particle size of the nano-nanometer zinc oxide is 30nm.

[0037] The preparation method specifically comprises the following steps:

[0038] (1) Get 50% water of formula consumption water total amount, add the nonylphenol polyoxyethylene ether of formula consumption, lauryl trimethyl ammonium chloride, glycerin cocoate, coconut oil monoisopropyl After alcohol amide, isocetyl stearate, polydimethylsiloxane, ethylene glycol, polyvinylpyrrolidone, ethylhexyl palmitate, propanol, ultrasonic dispersion, the frequency of ultrasonic dispersion is 50KHZ, time For 30 minutes, solution A was obtained;

[0039] (2) Heat the solution A obtained in step (1) to 70° C. and stir for 1 hour, then cool to 50° C., and the stirring speed is 400 r / min to obtain solution B;

[0040](3) Take the sodium hydroxide, sodium lauricate, ammonium persulfate, potassium chloride...

Embodiment 2

[0042] A kind of desizing agent of embodiment 2

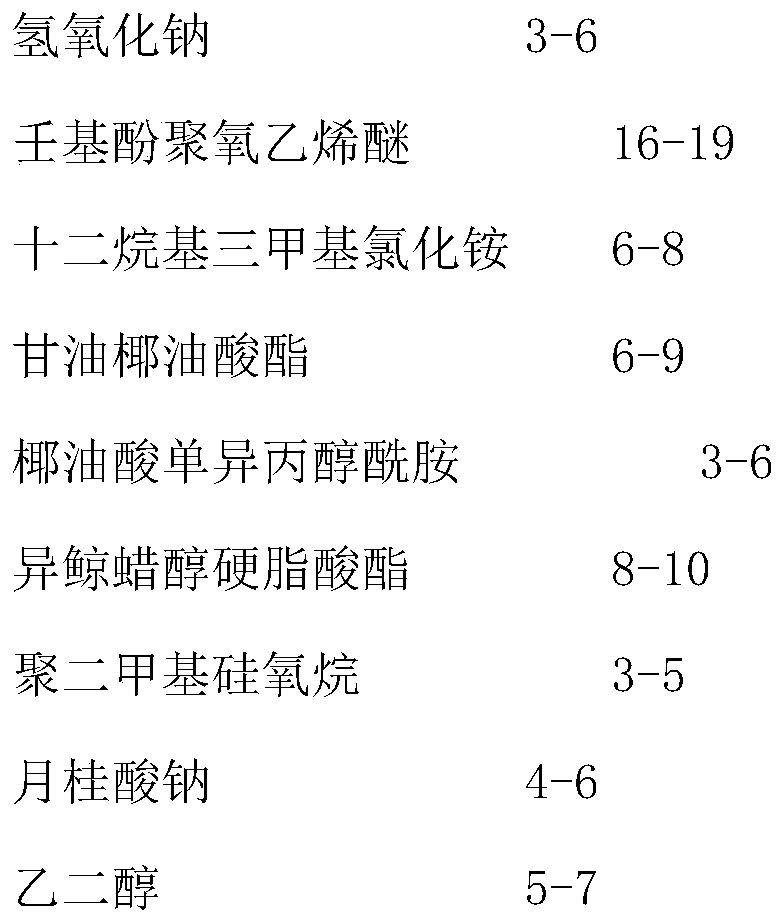

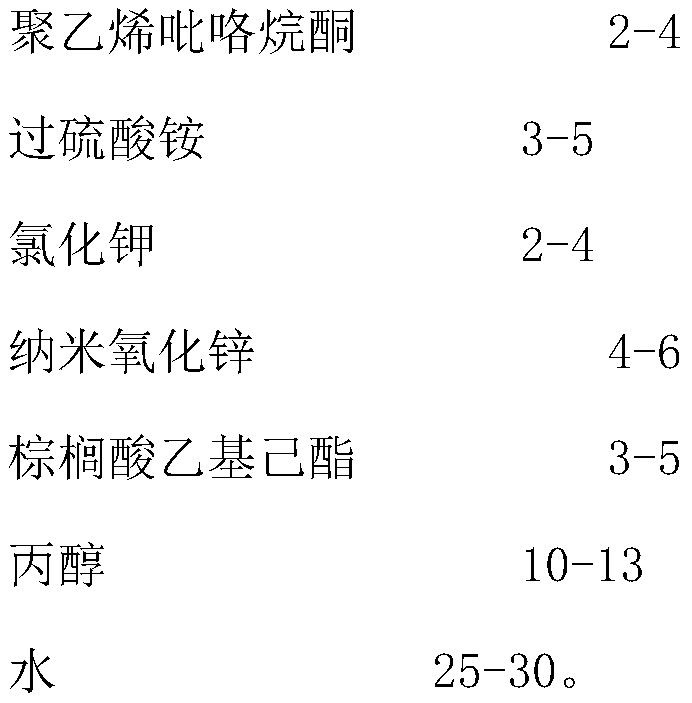

[0043] Formula, comprises by weight:

[0044]

[0045] Wherein the average particle size of nano zinc oxide is 50nm.

[0046] The preparation method specifically comprises the following steps:

[0047] (1) Get the water of 70% of formula consumption water total amount, add the nonylphenol polyoxyethylene ether of formula consumption, lauryl trimethyl ammonium chloride, glycerin cocoate, coconut oil monoisopropyl After alcohol amide, isocetyl stearate, polydimethylsiloxane, ethylene glycol, polyvinylpyrrolidone, ethylhexyl palmitate, propanol, ultrasonic dispersion, the frequency of ultrasonic dispersion is 50KHZ, time For 30 minutes, solution A was obtained;

[0048] (2) Heat the solution A obtained in step (1) to 90° C., stir and react for 1 hour, then cool to 30° C., and the stirring speed is 200 r / min to obtain solution B;

[0049] (3) Take the sodium hydroxide, sodium lauricate, ammonium persulfate, potassium chlorid...

Embodiment 3

[0051] A kind of desizing agent of embodiment 3

[0052] Formula, comprises by weight:

[0053]

[0054] Wherein the average particle size of nano zinc oxide is 35nm.

[0055] The preparation method specifically comprises the following steps:

[0056] (1) Get 65% of the water of formula consumption water total amount, add the nonylphenol polyoxyethylene ether of formula consumption, lauryl trimethyl ammonium chloride, glycerin cocoate, coconut oil monoisopropyl After alcohol amide, isocetyl stearate, polydimethylsiloxane, ethylene glycol, polyvinylpyrrolidone, ethylhexyl palmitate, propanol, ultrasonic dispersion, the frequency of ultrasonic dispersion is 50KHZ, time For 30 minutes, solution A was obtained;

[0057] (2) Heat the solution A obtained in step (1) to 85° C., stir and react for 1 hour, then cool to 45° C., and the stirring speed is 350 r / min to obtain solution B;

[0058] (3) Take the sodium hydroxide, sodium lauricate, ammonium persulfate, potassium chlorid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com