Durable anti-stripping ceramic adhesive

A ceramic adhesive and anti-peeling technology, applied in the field of building materials, can solve problems such as poor mechanical properties, and achieve the effect of improving anti-peeling strength, improving product durability and bonding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

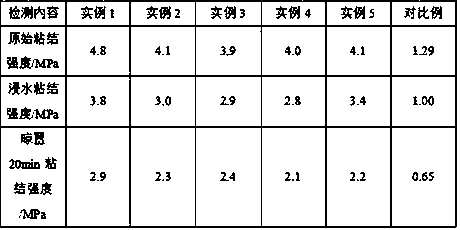

Examples

example 1

[0028] Put the isinglass powder and water in the No. 1 beaker according to the mass ratio of 1:5, stir and mix with a glass rod for 15 minutes, and then let it stand for swelling at room temperature for 8 hours, then place the No. In the container, at a temperature of 85°C and a rotational speed of 400r / min, heat, stir and mix for 50 minutes to obtain the swim bladder glue. In a magnetic stirrer with digital speed measurement and constant temperature, at a temperature of 75°C and a rotation speed of 500r / min, heat and stir for 60 minutes to hydrolyze. Adjust the pH to 10.8 with 10% sodium hydroxide solution to obtain the hydrolyzed solution of isinglass; put chitosan and water in a No. 2 beaker at a mass ratio of 1:40, stir and mix with a glass rod for 15 minutes, and then, at room temperature, After standing still for swelling for 4 hours, place the No. 2 beaker in a magnetic stirrer with digital speed measurement and constant temperature, and heat and stir for 50 minutes at ...

example 2

[0030] Put chitosan and water in the No. 2 beaker at a mass ratio of 1:40, stir and mix with a glass rod for 15 minutes, and then let it stand for swelling for 4 hours at room temperature, then place the No. In the container, at a temperature of 85°C and a rotating speed of 600r / min, heat, stir and mix for 50 minutes to obtain the swim bladder glue; in parts by weight, mix 40 parts of cement, 30 parts of bamboo vinegar, 40 parts of quartz sand, and 20 parts of Put 1 part of chitosan liquid, 8 parts of phospholipid, 8 parts of vegetable essential oil, 8 parts of surfactant, and 40 parts of water in a mixer, and stir and mix for 40 minutes at a speed of 200 r / min to obtain a durable anti-stripping ceramic binder. The cement is Portland cement. The quartz sand has a particle size of 0.3mm. The phospholipid is soybean phospholipid. The plant essential oil is rose essential oil. The surfactant is sodium dodecylbenzenesulfonate.

example 3

[0032] Put the isinglass powder and water in the No. 1 beaker according to the mass ratio of 1:5, stir and mix with a glass rod for 15 minutes, and then let it stand for swelling at room temperature for 8 hours, then place the No. In the container, at a temperature of 85°C and a rotational speed of 400r / min, heat, stir and mix for 50 minutes to obtain the swim bladder glue. In a magnetic stirrer with digital speed measurement and constant temperature, at a temperature of 75°C and a rotation speed of 500r / min, heat and stir for 60 minutes to hydrolyze. Adjust the pH to 10.8 with 10% sodium hydroxide solution to obtain the hydrolyzed solution of isinglass; put chitosan and water in a No. 2 beaker at a mass ratio of 1:40, stir and mix with a glass rod for 15 minutes, and then, at room temperature, After standing still for swelling for 4 hours, place the No. 2 beaker in a magnetic stirrer with digital speed measurement and constant temperature, and heat and stir for 50 minutes at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com