Method for preparing YAG transparent ceramics based on improved Isobam gel system

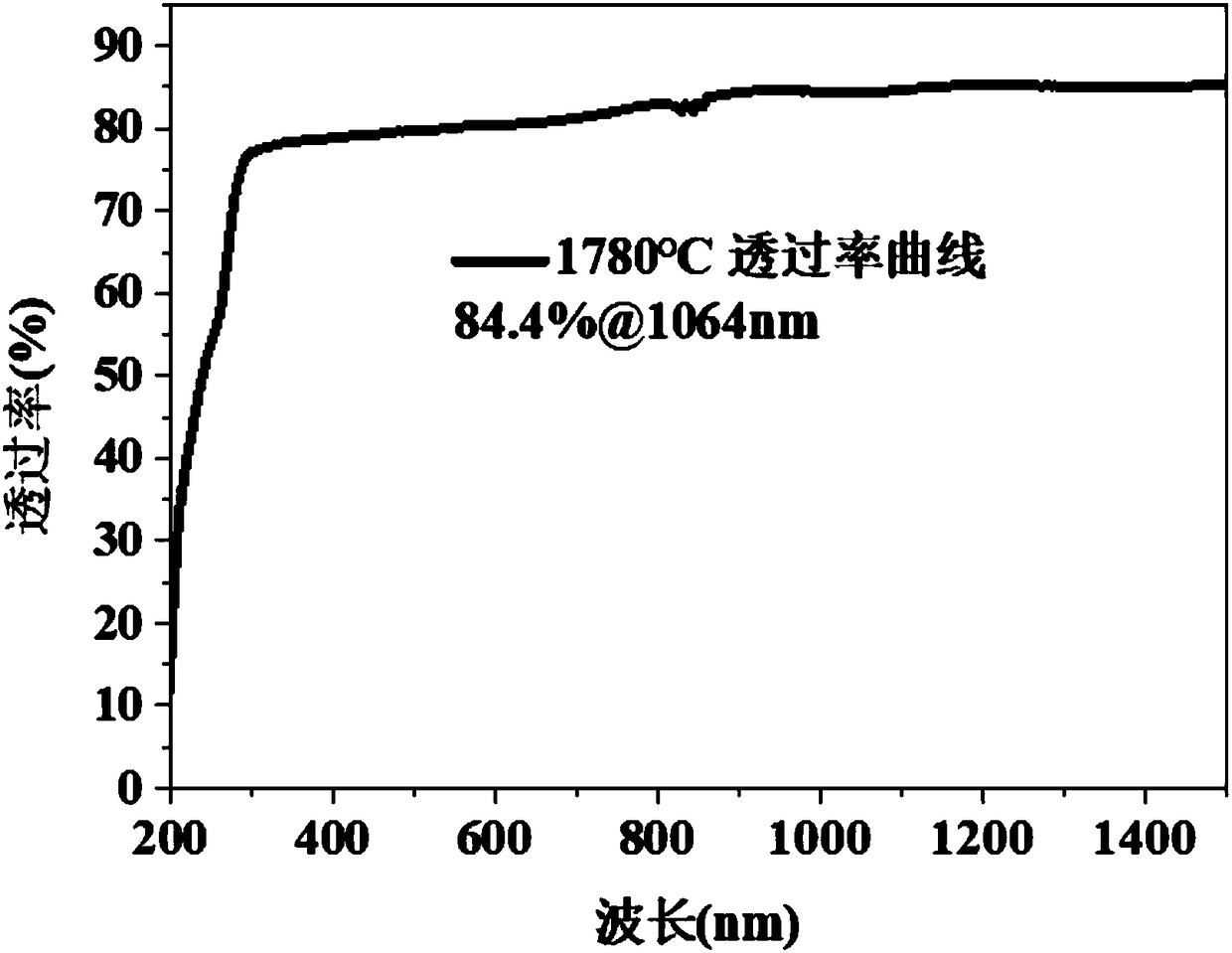

A technology of transparent ceramics and gels, applied in the field of transparent ceramics preparation, can solve the problems of reducing the transmittance of YAG transparent ceramics, insufficient densification of green bodies, affecting the efficiency of preparation, etc. The effect of improving transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for preparing YAG transparent ceramics based on improved Isobam gel system, it comprises the following steps:

[0046] Step 1. Follow Y 3 Al 5 o 12 The stoichiometric ratio of the molecular formula weighs the high-purity nano Y 2 o 3 Powder (average particle size: 500nm) 53.676g, high-purity nano-Al 2 o 3 Powder (average particle size: 200nm) 71.324g;

[0047] Step 2. Put 375g of high-purity alumina grinding balls, 156.25ml of absolute ethanol, 0.5ml of dispersant PEI, and sintering aid SiO 2 0.625g was put into a nylon ball mill jar together with the weighed nano-oxide powder, mixed and ball milled at a speed of 160r / min for 15 hours to obtain a mixed slurry A;

[0048] Step 3: Take out the mixed slurry A and place it in an oven at 60°C for 24 hours, pass through a 150-mesh sieve, place the sieved powder in a muffle furnace for calcination, and raise the temperature from room temperature to 700°C, the heating rate 2°C / min, keep warm for 8 hours, then ...

Embodiment 2

[0059] A method for preparing YAG transparent ceramics based on improved Isobam gel system, it comprises the following steps:

[0060] Step 1. Follow Y 3 Al 5 o 12 The stoichiometric ratio of the molecular formula weighs the high-purity nano Y 2 o 3 Powder (average particle size: 600nm) 34.352g, high-purity nano-Al 2 o 3 Powder (average particle size: 600nm) 45.648g;

[0061] Step 2. Put 80g of high-purity alumina grinding balls, 66.67ml of absolute ethanol, 0.08ml of dispersant PEI, and sintering aid SiO 2 Put 0.04g and MgO 0.04g together with the weighed nano-oxide powder into an alumina ceramic ball mill pot, mix and ball mill at a speed of 120r / min for 24 hours to obtain a mixed slurry A;

[0062] Step 3: Take out the mixed slurry A and place it in an oven at 50°C for 48 hours, pass through a 100-mesh sieve, place the sieved powder in a muffle furnace for calcination, and raise the temperature from room temperature to 800°C, the heating rate 2°C / min, keep warm for...

Embodiment 3

[0070] A method for preparing YAG transparent ceramics based on improved Isobam gel system, it comprises the following steps:

[0071] Step 1. Follow Y 3 Al 5 o 12 The stoichiometric ratio of the molecular formula weighs the high-purity nano Y 2 o 3 Powder (average particle size: 550nm) 214.703g, high-purity nano-Al 2 o 3 Powder (average particle size: 400nm) 285.297g;

[0072] Step 2. Put 1200g of high-purity alumina grinding balls, 604.17ml of absolute ethanol, 4ml of dispersant PEI, and sintering aid SiO 2 1.25 g was put into a polytetrafluoroethylene ball mill jar together with the weighed nano-oxide powder, and mixed and ball milled at a speed of 150 r / min for 20 hours to obtain a mixed slurry A;

[0073] Step 3: Take out the mixed slurry A and place it in an oven at 55°C for 36 hours, pass through a 200-mesh sieve, place the sieved powder in a muffle furnace for calcination, and raise the temperature from room temperature to 900°C. 3°C / min, keep warm for 7 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com