Preparation method and application of boron nitride foams

A technology of boron nitride and foam, applied in chemical instruments and methods, applications, inorganic chemistry, etc., can solve problems such as overcooling and leakage, and achieve the effects of low reaction temperature, low energy consumption, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] (1) a preparation method of boron nitride foam, comprising the steps of:

[0034] 1) Dissolving boron source and nitrogen source in water to obtain a colorless and transparent solution; the boron source is boric acid, phenylboronic acid, sodium borohydride, boramine or borax. The nitrogen source is urea, melamine, biuret, ammonium borate, ammonium chloride, ammonium nitrate or dicyandiamide. In molar ratio, boron source: nitrogen source=1: (1-10).

[0035] 2) Add the template agent to the colorless transparent solution obtained in step 1), pull and soak repeatedly, and dry the obtained product to obtain the precursor. The template agent is melamine sponge, mineral wool or cotton fabric. The drying is vacuum drying, vacuum freeze drying or blast drying.

[0036] 3) Put the precursor obtained in step 2) in a high-temperature furnace, and under the protection of an inert gas, raise the temperature to 800-1900°C at a heating rate of 1-15°C / min, and react at this temperat...

Embodiment 1

[0042] (1) The preparation method is as follows:

[0043] 1) Dissolve 0.1 mol of boric acid and 0.3 mol of urea in 80 mL of 45°C water under magnetic stirring at a molar ratio of 1:3 to obtain a colorless and transparent solution.

[0044] 2) Put the melamine sponge into the colorless transparent solution, pull and soak repeatedly until the melamine sponge is saturated, then place it in a vacuum freeze dryer, and dry it for 48 hours at a temperature of -50°C and a pressure of 26Pa , to obtain a white bulk precursor.

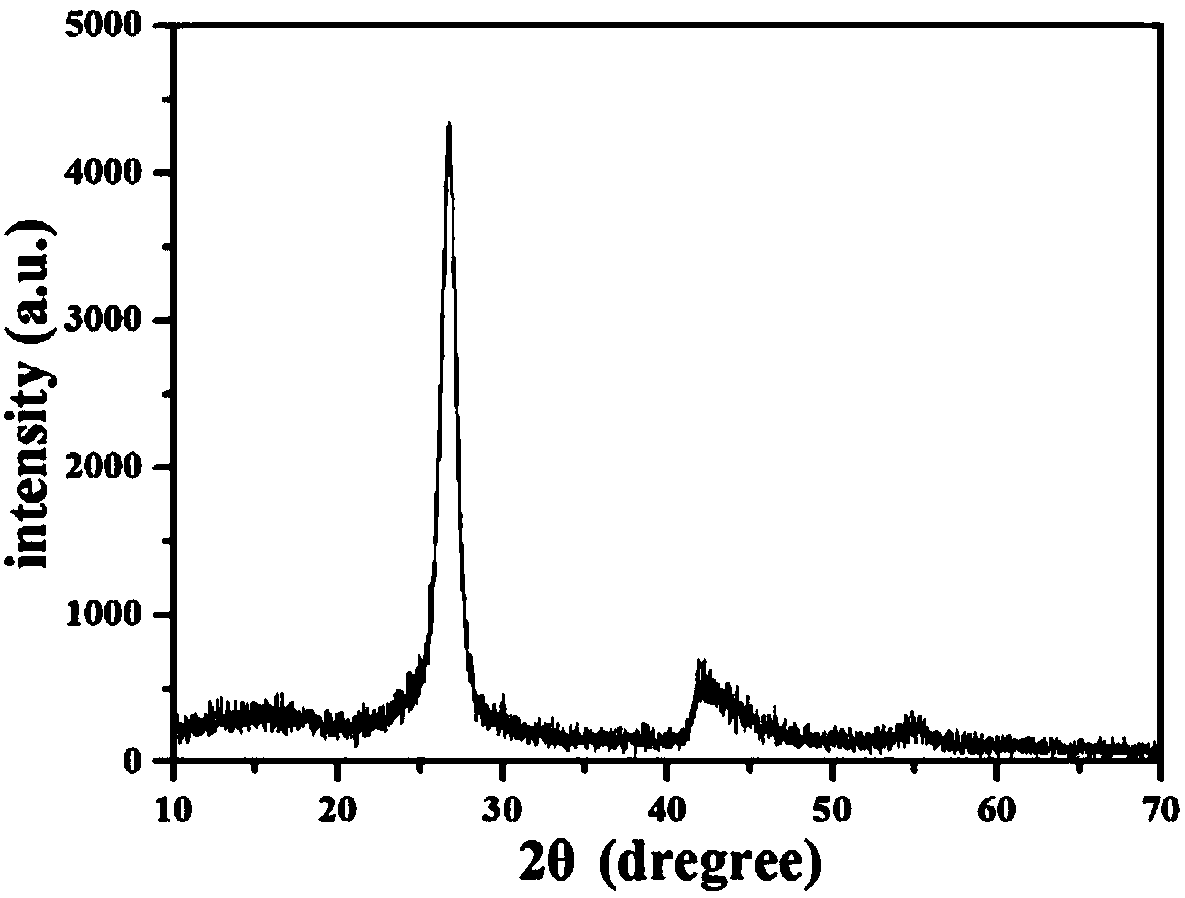

[0045] 3) Put the white bulk precursor in a high-temperature furnace, raise the temperature to 1000°C at a rate of 5°C / min under a nitrogen protective gas, and react at this temperature for 3 hours to obtain a crude product.

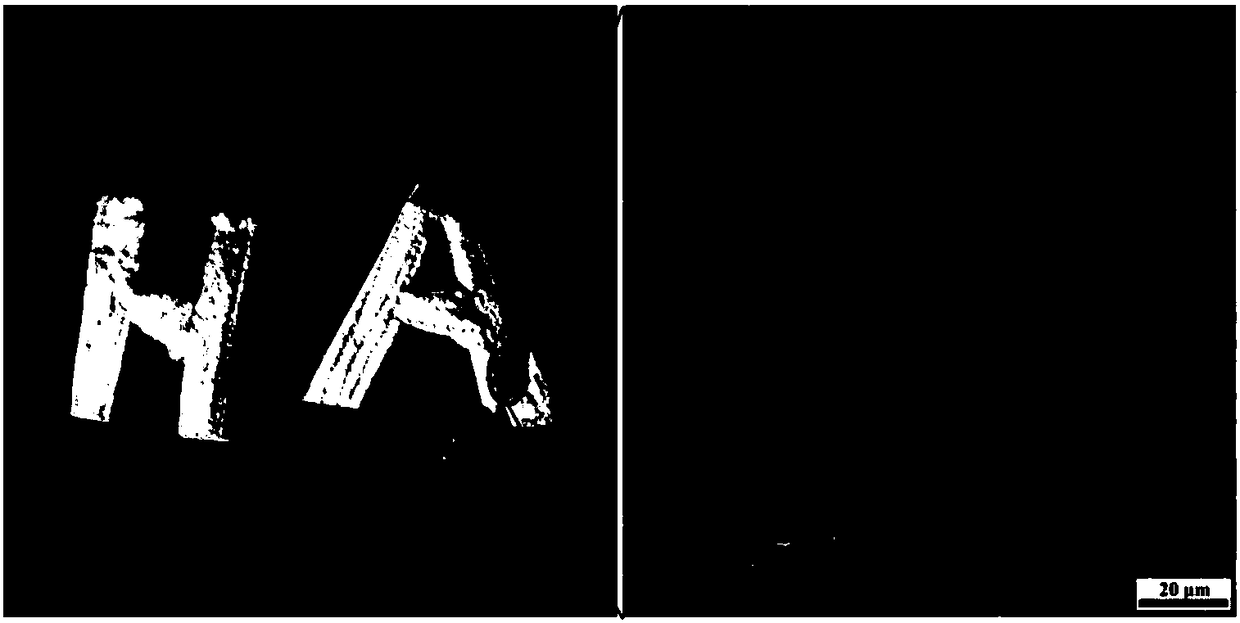

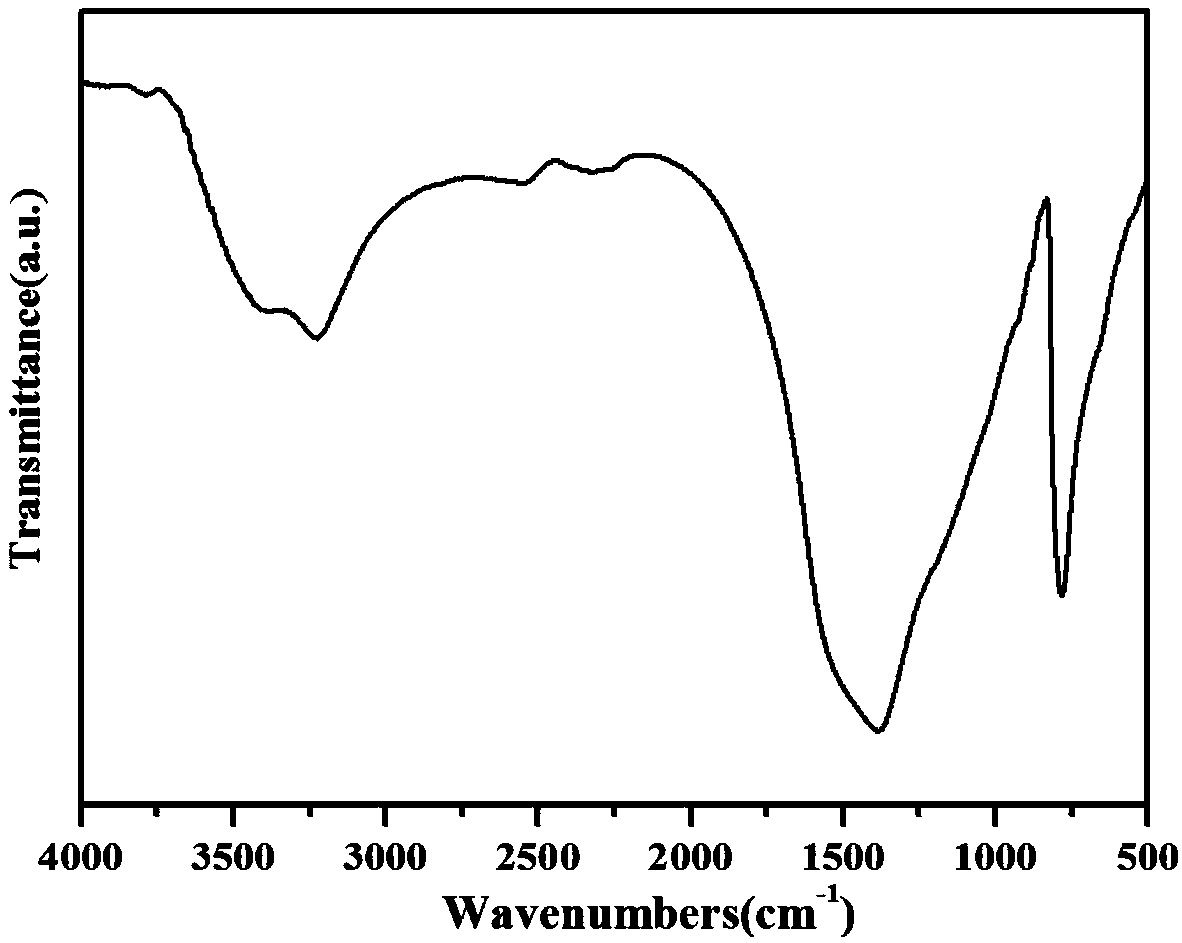

[0046] 4) Place the obtained crude product in ethanol and water for ultrasonication for 5 hours, and then place it in a vacuum drying oven at 110° C. for 12 hours to obtain a boron nitride foam with a yield of 80.1% and a purity of 99.3%, ...

Embodiment 2

[0052] The method is the same as in Example 1, except that the molar ratio of boric acid and urea is changed to 1:1, 1:5, 1:7, and the results are shown in Table 1.

[0053] Table 1

[0054]

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com