Silver nanowire mesh-reduced graphene oxide combined electrode and preparation method thereof

A graphene composite, silver nanowire technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of difficult operation, high cost, and easy transfer of graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing a silver nanowire grid-reduced graphene oxide composite electrode, comprising the following steps:

[0024] Depositing silver nanowires on the surface of the substrate to form a grid of silver nanowires;

[0025] A graphene oxide aqueous solution is coated on the surface of the silver nanowire grid, and a silver nanowire grid-graphene oxide composite film is formed on the surface of the substrate;

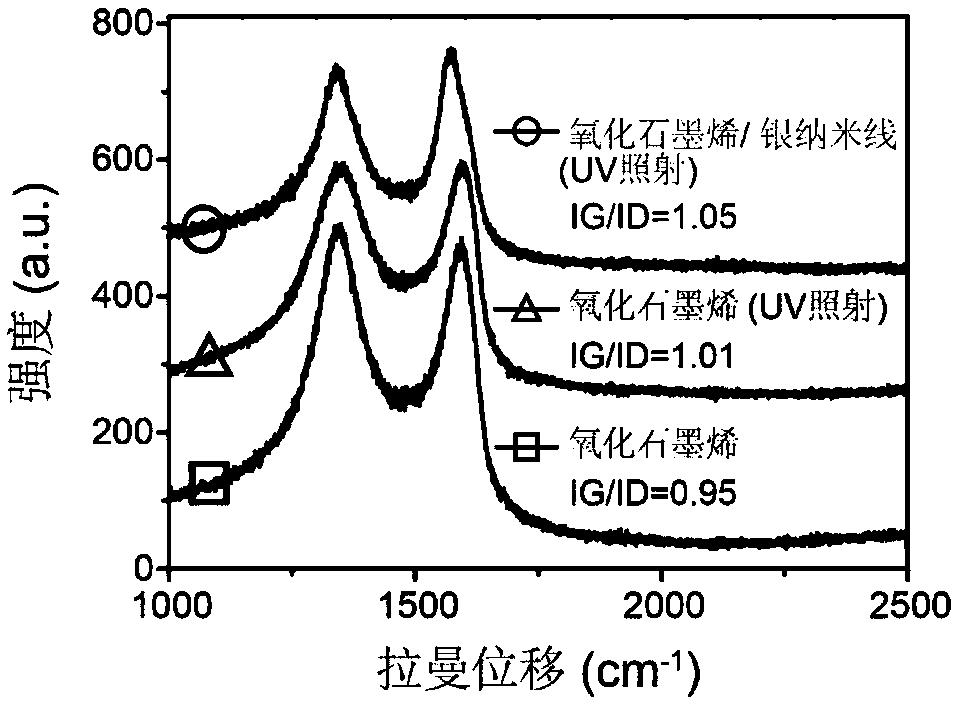

[0026] The silver nanowire grid-graphene oxide composite film is irradiated with ultraviolet rays to obtain a silver nanowire grid-reduced graphene oxide composite electrode.

[0027] The invention deposits silver nanowires on the substrate surface to form silver nanowire grids. In the present invention, the substrate is preferably a flexible substrate, more preferably a polyethylene terephthalate (PET) substrate or a polyimide (PI) substrate; There is no special requirement for the thickness of the substrate, and a substrate w...

Embodiment 1

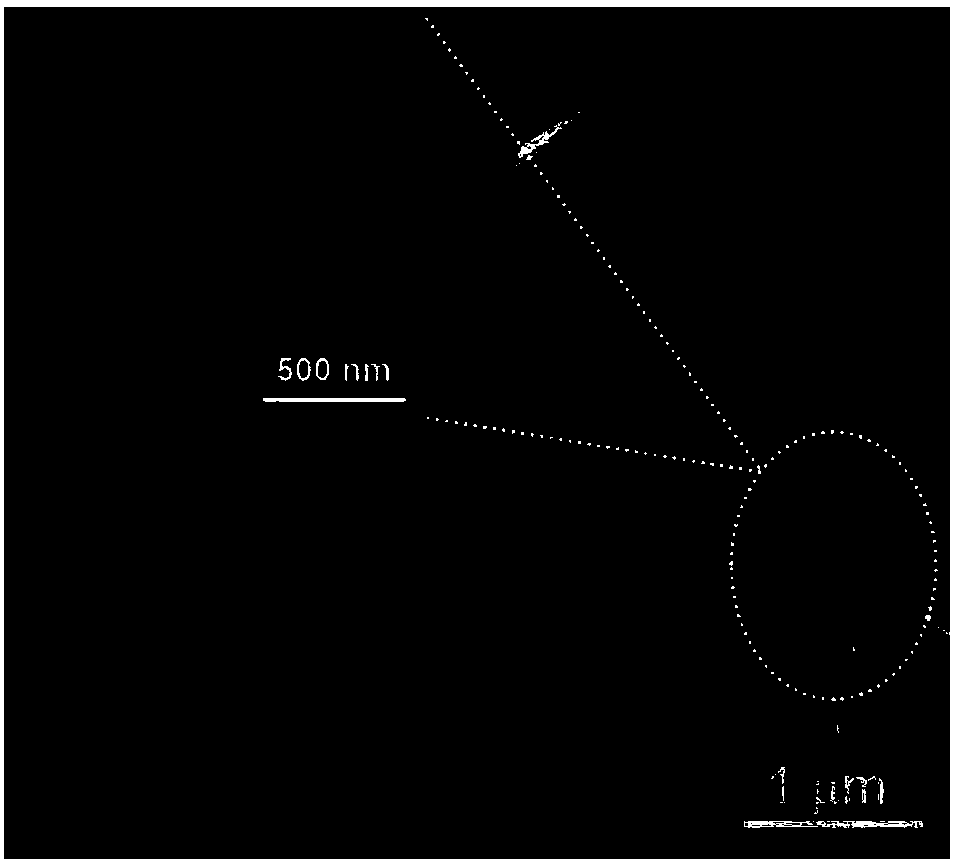

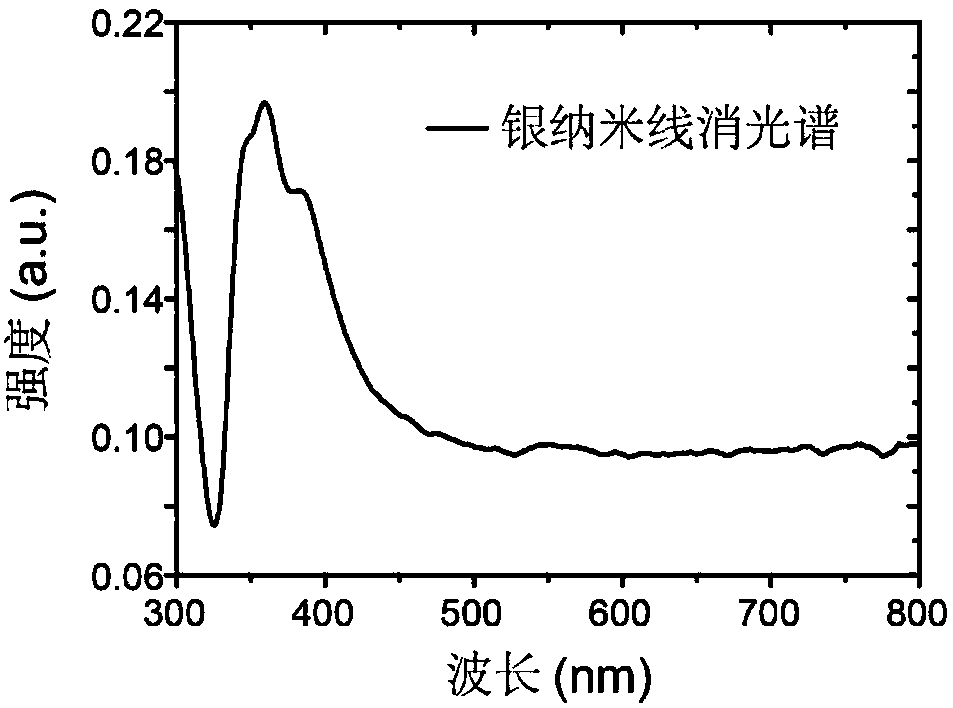

[0042] (1) Drop-coat silver nanowire ethanol solution on a flexible PET substrate with an area of 1 × 1 cm (wherein the concentration of silver nanowire ethanol solution is 0.1 mg / mL, and the single drop-coating amount is 10 μL, and drop-coating 10 times, The average diameter of the silver nanowires is 90nm, and the length is 10 μm). After the drop coating is completed, the ethanol solvent is naturally volatilized to dry, and the silver nanowire grids randomly arranged on the substrate surface are obtained. The silver nanowire grids on the substrate The deposition amount is 100mg / m 2 ;

[0043] (2) 30 μL of graphene oxide aqueous solution (concentration: 0.1 mg / mL) was drip-coated on the surface of the silver nanowire grid. After the drip coating was completed, the surface moisture was evaporated to dryness to form silver nanowires and graphene oxide Composite film;

[0044] (3) Use a UV mercury lamp to irradiate the silver nanowire grid-graphene oxide composite film with ...

Embodiment 2

[0051] (1) Drop-coat silver nanowire ethanol solution on a flexible PI substrate with an area of 1 × 1 cm (the concentration of silver nanowire ethanol solution is 0.1 mg / mL, and the single drop-coating volume is 6 μL, and drop-coating 10 times, The average diameter of the silver nanowires is 80nm, and the length is 10 μm). After the drop coating is completed, the ethanol solvent is naturally volatilized to dry, and a randomly arranged silver nanowire grid is obtained on the substrate surface. The deposition of the silver nanowire grid on the substrate The amount is 60mg / m 2 ;

[0052] (2) 20 μL of graphene oxide aqueous solution (concentration: 0.1 mg / mL) was drip-coated on the surface of the silver nanowire grid. After the drip coating was completed, the surface moisture was evaporated to dryness to form silver nanowires and graphene oxide on the surface Composite film;

[0053] (3) Use a UV mercury lamp to irradiate the silver nanowire grid-graphene oxide composite film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com