High-strength and corrosion-resistant plastic sheet pile and preparation method thereof

A corrosion-resistant, plastic sheet technology, applied in the field of high-strength corrosion-resistant plastic sheet piles and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

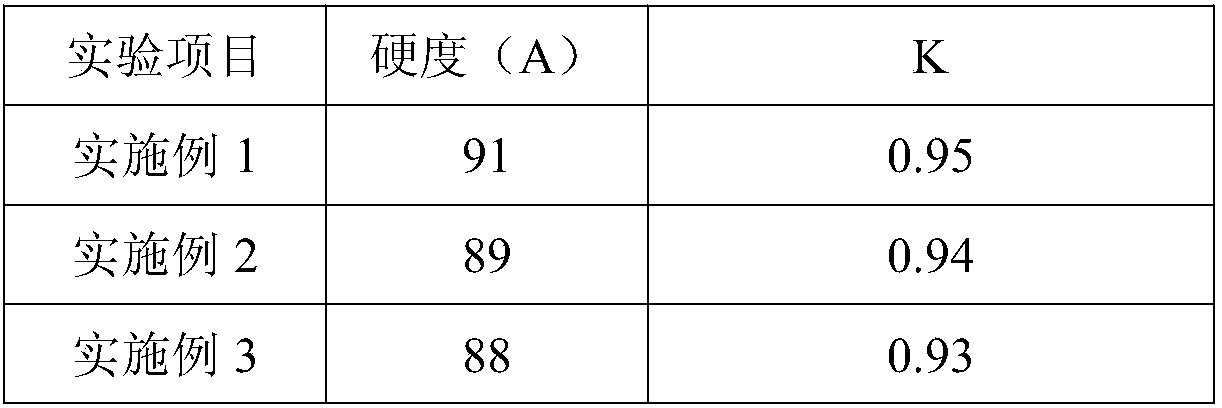

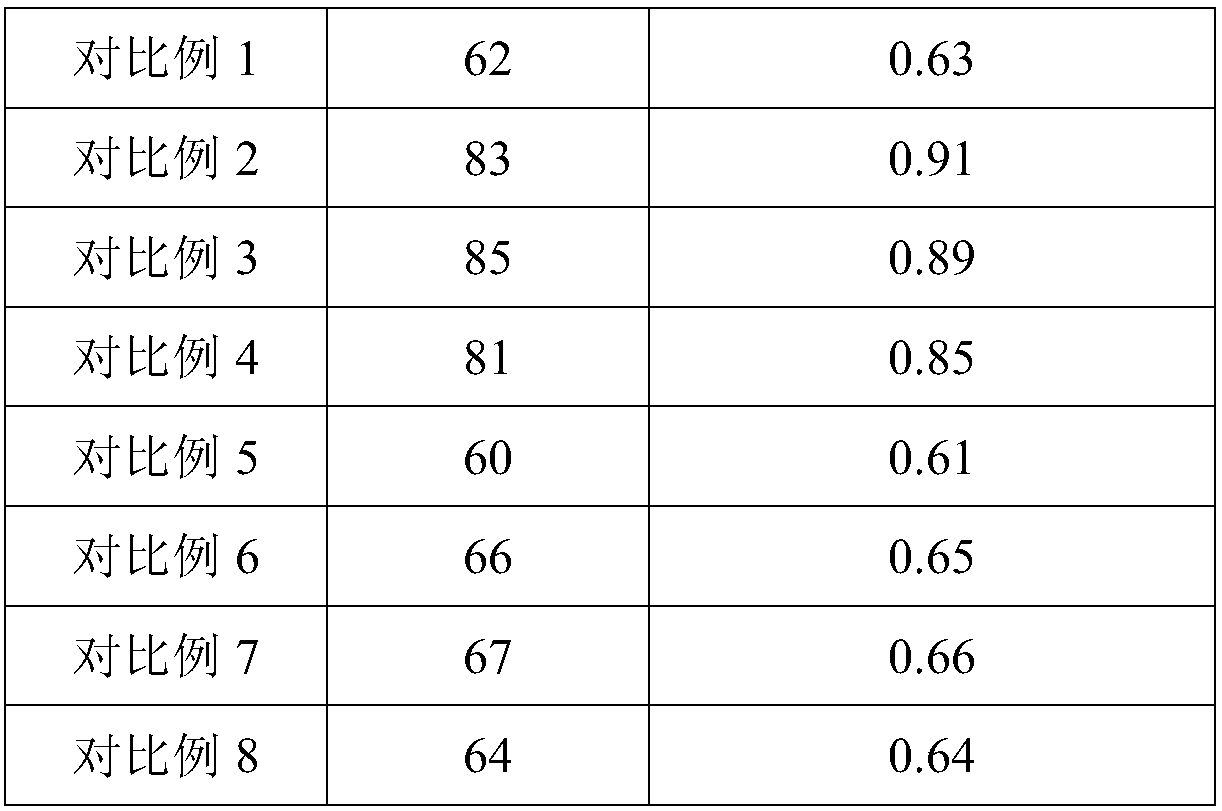

Examples

preparation example Construction

[0032] The preparation method of the high-strength corrosion-resistant plastic sheet pile comprises the following steps:

[0033] (1) Weigh polyvinyl chloride, plasticizer, filler, heat stabilizer, ultraviolet absorber, vinylpyridine, vinylpyrimidine, initiator, zirconia fiber, rosin thermal polymer, all-aromatic Mix the copolyester in a high-speed mixer for 3-5 minutes;

[0034] (2) placing each component mixed in a parallel twin-screw extruder through melt extrusion and granulation;

[0035] (3) Melt the plastic granules obtained in step 2 into a mold in a molding machine.

Embodiment 1

[0037] A high-strength corrosion-resistant plastic sheet pile, comprising the following raw materials: 100 parts of polyvinyl chloride, 20 parts of plasticizer, 12.5 parts of filler, 3 parts of heat stabilizer, 0.5 part of ultraviolet absorber, 20 parts of vinylpyridine, 10 parts of vinylpyrimidine, 0.05 parts of initiator, 7.5 parts of zirconia fiber, 6 parts of rosin thermopolymer, 15 parts of fully aromatic copolyester.

[0038] The plasticizer is a phthalate plasticizer.

[0039] The filler is calcium carbonate.

[0040] The heat stabilizer is a basic lead salt heat stabilizer.

[0041] The initiator is a peroxyester.

[0042] The ultraviolet absorber is a salicylate ultraviolet absorber.

[0043] The preparation method of the high-strength corrosion-resistant plastic sheet pile comprises the following steps:

[0044] (1) Weigh polyvinyl chloride, plasticizer, filler, heat stabilizer, ultraviolet absorber, vinylpyridine, vinylpyrimidine, initiator, zirconia fiber, rosi...

Embodiment 2

[0048] A high-strength corrosion-resistant plastic sheet pile, comprising the following raw materials: 100 parts of polyvinyl chloride, 22 parts of plasticizer, 10 parts of filler, 4 parts of heat stabilizer, 0.1 part of ultraviolet absorber, 16 parts of vinylpyridine, 12 parts of vinyl pyrimidine, 0.01 part of initiator, 10 parts of zirconia fiber, 4 parts of rosin thermal polymer, 20 parts of fully aromatic copolyester.

[0049] The plasticizer is a glutarate plasticizer.

[0050] The filler is talcum powder.

[0051] The heat stabilizer is an organotin heat stabilizer.

[0052] The initiator is peroxycarbonate.

[0053] The ultraviolet absorber is a benzophenone ultraviolet absorber.

[0054] The preparation method of the high-strength corrosion-resistant plastic sheet pile comprises the following steps:

[0055] (1) Weigh polyvinyl chloride, plasticizer, filler, heat stabilizer, ultraviolet absorber, vinylpyridine, vinylpyrimidine, initiator, zirconia fiber, rosin ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com