Method for preparing hexagonal copper sulfide nano-sheets

A nanosheet, copper sulfide technology, applied in copper sulfide, nanotechnology, nanotechnology and other directions, to achieve the effect of low cost, high efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A preparation method for hexagonal copper sulfide nanosheets, comprising the following steps:

[0023] Mix copper salt and long-chain alkylamine, heat and vacuumize to dissolve, so that copper ions and amine groups are complexed to form reaction solution A; the molar concentration of copper salt is 0.10-0.50mol L -1 ;

[0024] Heat and dissolve sulfur powder and long-chain alkylamine to form reaction solution B; the molar concentration of sulfur powder is 0.50-5.0mol L -1 ;

[0025] At a reaction temperature of 80-180°C, add reaction solution B to reaction solution A to form a mixed solution, keep warm and react for 0.5-24 hours; wherein the molar ratio of copper salt and sulfur powder is 1:2-1:4;

[0026] After the reaction is finished, absolute ethanol is added to the mixed solution to precipitate the copper sulfide nanosheets from the solution, and the precipitated material is centrifugally washed and dried with absolute ethanol to obtain copper sulfide nanosheets ...

Embodiment 1

[0034] A preparation method for hexagonal copper sulfide nanosheets, comprising the following steps:

[0035] Add 6 mmol of cuprous chloride and 40 ml of dodecylamine into the reaction vessel, heat to 100°C, vacuumize for 30 minutes, and keep for 4 hours.

[0036] Heat 18mmol of sulfur powder and 20ml of dodecylamine to 95°C to dissolve them, then quickly add the sulfur powder solution into the copper salt solution prepared in ①, and react at 95°C for 9h. After the reaction is over, add enough absolute ethanol to the solution to precipitate the copper sulfide nanosheets from the solution, and the precipitated material is centrifugally washed and dried with absolute ethanol to obtain hexagonal copper sulfide nanosheets with a yield of 87 %.

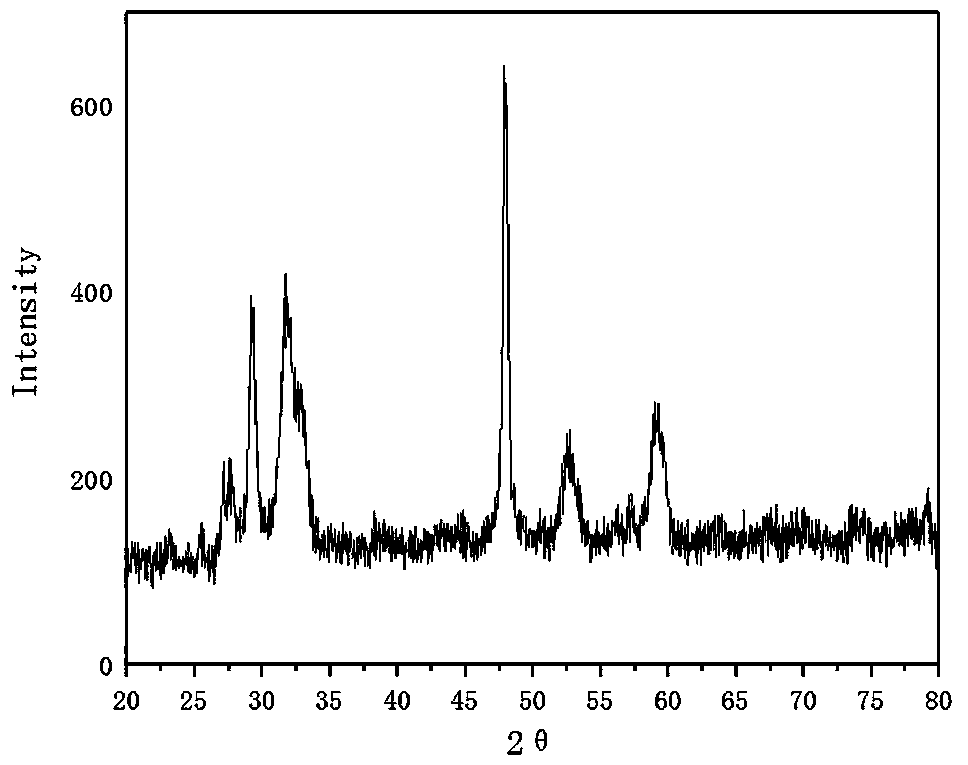

[0037] The X-ray diffraction pattern of the obtained hexagonal copper sulfide nanosheets is as follows figure 1 shown. Depend on figure 1 It can be seen that the prepared material is copper sulfide with a hexagonal indigoxite structure...

Embodiment 2

[0039] Add 6mmol of cuprous chloride and 30ml of octadecylamine into the reaction vessel, heat to 100°C, vacuumize for 30 minutes, and keep for 4h.

[0040] Heat 12mmol of sulfur powder and 10ml of octadecylamine to 95°C to dissolve them, then quickly add the sulfur powder solution to the copper salt solution prepared in ①, and react at 120°C for 6h. After the reaction is over, add enough absolute ethanol to the solution to precipitate the copper sulfide nanosheets from the solution, and the precipitated material is centrifugally washed and dried with absolute ethanol to obtain hexagonal copper sulfide nanosheets with a yield of 86 %.

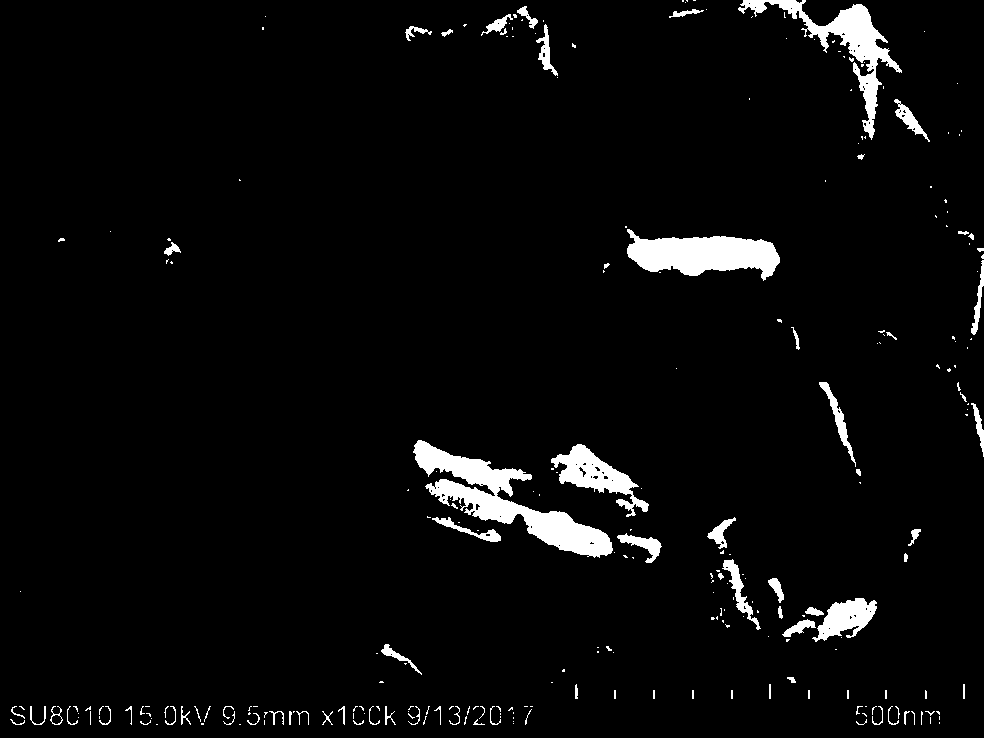

[0041] Figure 4 is a scanning electron micrograph of the obtained hexagonal copper sulfide nanosheets. As can be seen from the figure, the hexagonal copper sulfide nanosheets are similar to the copper sulfide nanosheets obtained in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com