A kind of non-bituminous base waterproof roll material and preparation method thereof

A waterproof membrane, non-bitumen-based technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc. Poor water channeling performance, restricting the scope of application and development, etc., to achieve the effects of shortening the burning time, good flame retardant effect, and preventing spread and diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

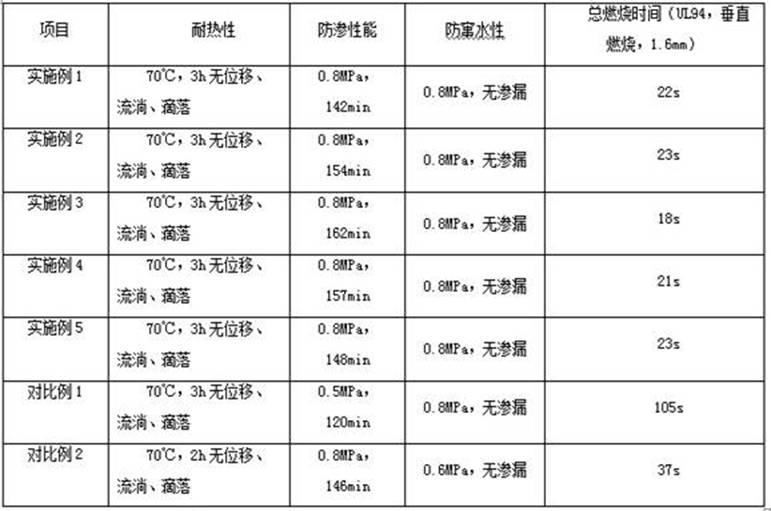

Examples

Embodiment 1

[0024] Embodiment 1 A kind of non-bituminous base waterproof roll material

[0025] A non-bitumen-based waterproof membrane of the present invention is composed of HDPE sheets and rubber layers, wherein the rubber layer includes the following raw materials: epoxy resin, allyl alcohol epoxy group-terminated polyether, ethylene Pyrrolidone-vinyl acetate copolymer, styrene-butadiene rubber, phenylphosphine oxychloride and 4,4'-diaminodiphenylmethane, viscosity reducer, cement compatibilizer and linear low-density polyethylene;

[0026] The raw materials include by weight: 25 parts of epoxy resin, 15 parts of allyl alcohol epoxy-terminated polyether, 15 parts of vinylpyrrolidone-vinyl acetate copolymer, 10 parts of styrene-butadiene rubber, phenyl oxychlorinated 1.5 parts of phosphine, 1.6 parts of 4,4'-diaminodiphenylmethane, 10 parts of viscosity reducer, 10 parts of cement affinity agent and 5 parts of linear low density polyethylene;

[0027] The epoxy resin has an epoxy valu...

Embodiment 2

[0031] Embodiment 2 A kind of non-bituminous base waterproof membrane

[0032] A non-bitumen-based waterproof membrane of the present invention is composed of HDPE sheets and rubber layers, wherein the rubber layer includes the following raw materials: epoxy resin, allyl alcohol epoxy group-terminated polyether, ethylene Pyrrolidone-vinyl acetate copolymer, styrene-butadiene rubber, phenylphosphine oxychloride and 4,4'-diaminodiphenylmethane, viscosity reducer, cement compatibilizer and linear low-density polyethylene;

[0033] The raw materials include by weight: 30 parts of epoxy resin, 18 parts of allyl alcohol epoxy-terminated polyether, 19 parts of vinylpyrrolidone-vinyl acetate copolymer, 12 parts of styrene-butadiene rubber, phenyl oxychlorinated 2.2 parts of phosphine, 2 parts of 4,4'-diaminodiphenylmethane, 14 parts of viscosity reducer, 13 parts of cement affinity agent and 6 parts of linear low density polyethylene;

[0034] The epoxy resin has an epoxy value of 0....

Embodiment 3

[0038] Embodiment 3 A kind of non-bituminous base waterproof roll material

[0039] A kind of non-bitumen-based waterproof membrane of the present invention is formed by compounding HDPE sheet layer and rubber material layer, wherein the rubber material layer, raw materials include by weight: 45 parts of epoxy resin, allyl alcohol epoxy group capping 30 parts of polyether, 32 parts of vinylpyrrolidone-vinyl acetate copolymer, 16 parts of styrene-butadiene rubber, 2.5 parts of phenylphosphine oxychloride, 2.7 parts of 4,4'-diaminodiphenylmethane, 25 parts of viscosity reducer, 15 parts of cement compatibilizer and 8 parts of linear low density polyethylene;

[0040] The epoxy resin has an epoxy value of 0.33-0.35eq / 100g, and an inorganic chlorine content≤55×10 -6 , volatile matter≤8-10%;

[0041] The allyl alcohol epoxy-terminated polyether has an acid value of 0.05 mgKOH / g, a degree of unsaturation of 0.98 mmol / g, a moisture content of 0.12%, and an epoxy value of 0.08 mol / 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com