Polylactic acid scarf polyurethane environment-friendly waterproof coating and preparation process thereof

A waterproof coating and polylactic acid technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of reducing the degree of polymerization and physical strength of polylactic acid, poor mechanical properties, environmental pollution, etc., and achieve improved biodegradability and compatibility Capacitance, strengthen the skeleton strength, improve the effect of hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

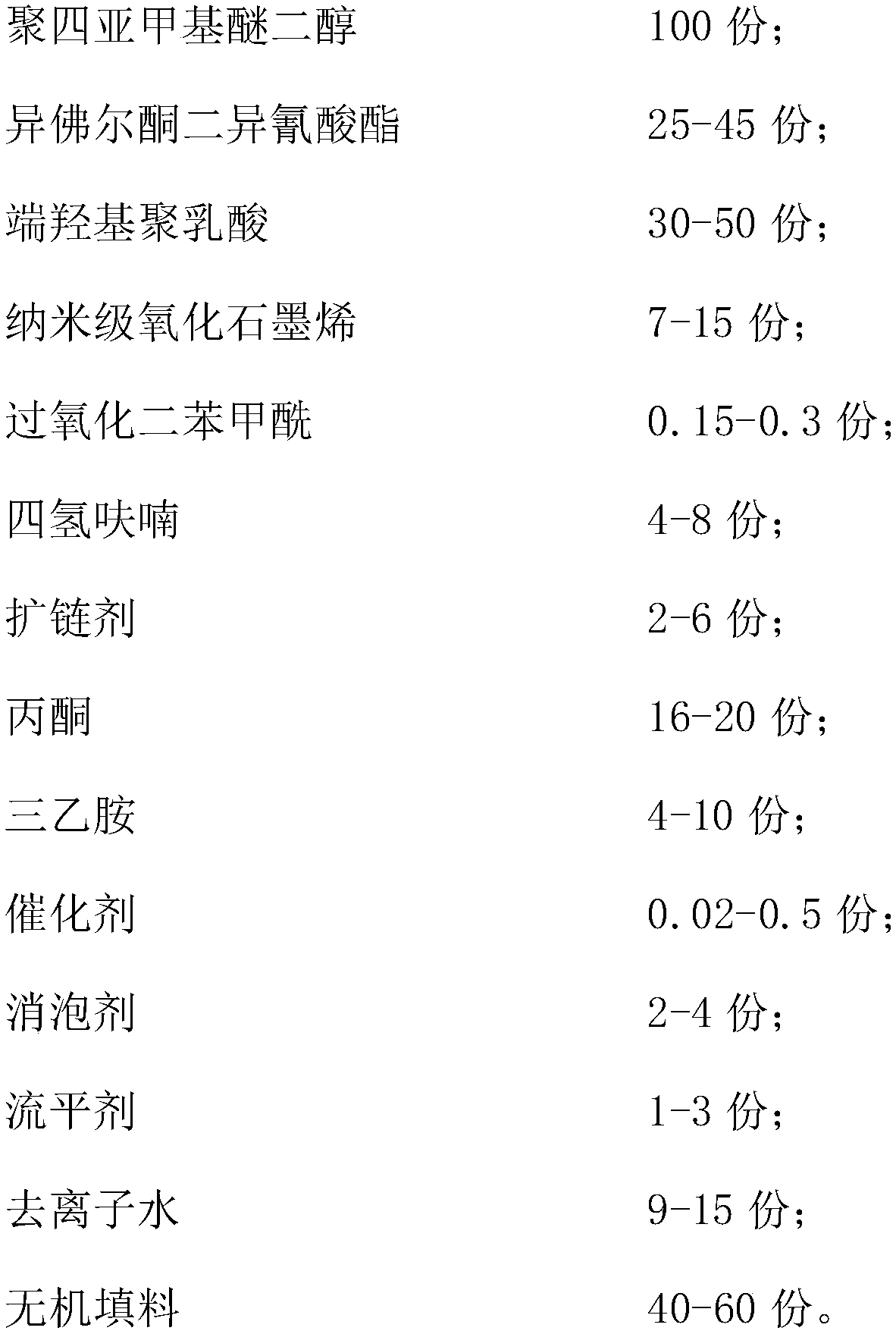

[0022] A polylactic acid embedded polyurethane environment-friendly waterproof coating comprises the following components in parts by weight:

[0023]

[0024]

[0025] The present invention also provides a preparation process of the above-mentioned polylactic acid embedding polyurethane environment-friendly waterproof coating, comprising the following steps:

[0026] S1: Dissolve hydroxyl-terminated polylactic acid with a molecular weight of 500 in tetrahydrofuran, then heat to 100°C, introduce nano-scale graphene oxide and dibenzoyl peroxide, and stir for 30 hours under the protection of an inert gas to obtain a graphene graft. Dendritic polylactic acid;

[0027] S2: In a vacuum environment at 100°C, dehydrate and dry polytetramethylene ether glycol. When the water content drops to 60%, add isophorone diisocyanate and catalyst, and in an inert gas environment at 65°C and 0.1MPa In, carry out nucleophilic addition reaction, obtain polyurethane prepolymer;

[0028] S3:...

Embodiment 2

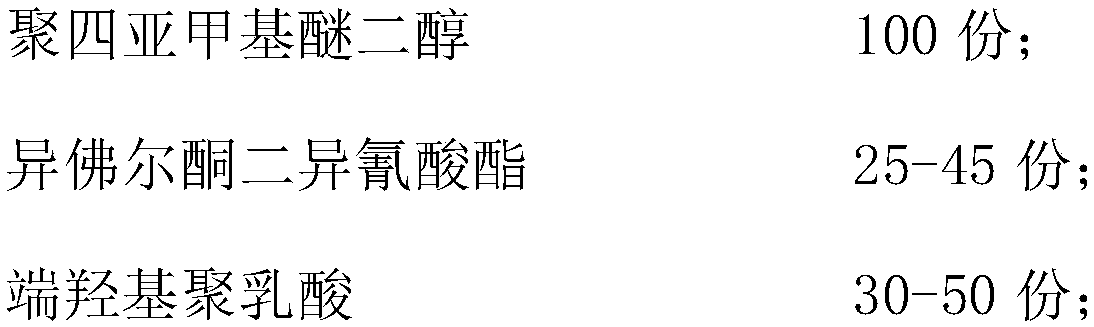

[0031] A polylactic acid embedded polyurethane environment-friendly waterproof coating comprises the following components in parts by weight:

[0032]

[0033]

[0034] The preparation method of above-mentioned waterproof paint is with embodiment 1, difference is:

[0035] S1: The molecular weight of hydroxyl-terminated polylactic acid is 1500, and the stirring reaction temperature and time are 120°C and 45h, respectively;

[0036] S2: The dehydration temperature is 110°C, and the nucleophilic addition reaction temperature is 70°C;

[0037] S3: heat preservation and stirring reaction time is 2h;

[0038] S4: The stirring speed is 4000 rpm.

Embodiment 3

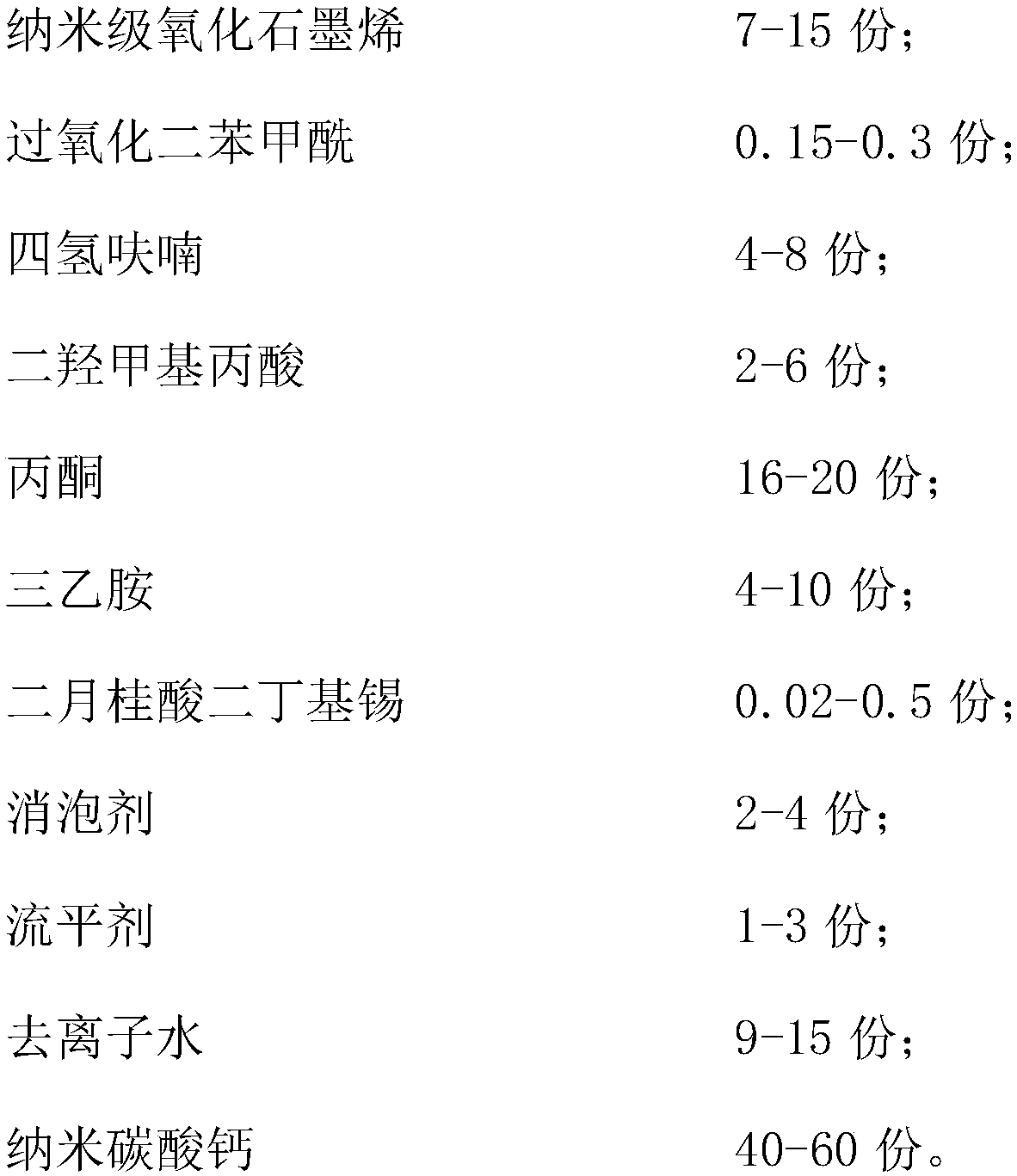

[0040] A polylactic acid embedded polyurethane environment-friendly waterproof coating comprises the following components in parts by weight:

[0041]

[0042]

[0043] The preparation method of above-mentioned waterproof paint is with embodiment 1, difference is:

[0044] S1: The molecular weight of hydroxyl-terminated polylactic acid is 2500, and the stirring reaction temperature and time are 140°C and 60h, respectively;

[0045] S2: The dehydration temperature is 120°C, and the nucleophilic addition reaction temperature is 75°C;

[0046] S3: heat preservation and stirring reaction time is 3h;

[0047] S4: The stirring speed is 5000 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com