High hardness titanium alloy and preparing method thereof

A titanium alloy and high hardness technology, applied in the field of high hardness titanium alloy and its preparation, can solve the problems of not being suitable for industrial production, high manufacturing cost, complicated process, etc., and achieve the effect of good performance, good thermal stability and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Preparation and detection of titanium alloy material (1)

[0041] The composition ratio of the titanium alloy prepared in this embodiment is Ti-6Al-2.5Sn-3Zr-2Mo-0.5V-0.5Cr-1Nb (6Al means Al with a weight percentage content of 6%, and the following similar expressions are the same), titanium alloy aluminum The equivalent is 8.13, and the molybdenum equivalent is 3.49. The raw materials for titanium alloy preparation are Al-Sn50, Al-Mo80, Al-V60, Al-Nb62, electrolytic chromium, aluminum beans, zirconium sponge and grade 0 titanium sponge.

[0042] The specific preparation process is:

[0043] (1) According to the design composition, the raw materials are mixed and then pressed to obtain electrodes, which are smelted in a vacuum consumable electric arc furnace three times to obtain ingots;

[0044] (2) The alloy adopts three-fire forging process, blank forging: 1150°C, deformation amount 50%; second-fire forging: 960°C, deformation amount 50%; third-fire forg...

Embodiment 2

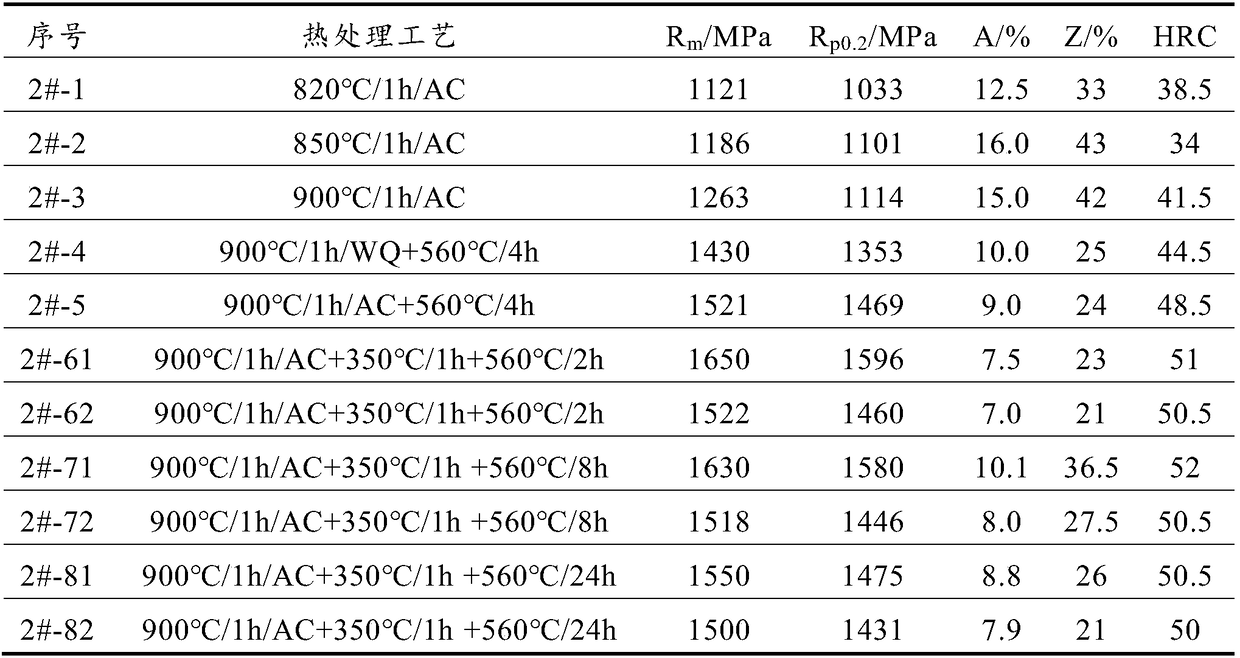

[0048] Embodiment 2: Preparation and detection of titanium alloy material (two)

[0049] The composition ratio of the titanium alloy prepared in this example is Ti-6.5Al-2Sn-2.5Zr-2.5Mo-1.5V-2Cr-2Nb, the aluminum equivalent of the titanium alloy is 8.38, and the molybdenum equivalent is 7.52. The raw materials for titanium alloy preparation are Al-Sn50, Al-Mo80, Al-V60, Al-Nb62, electrolytic chromium, aluminum beans, zirconium sponge and grade 0 titanium sponge.

[0050] The specific preparation process is:

[0051] (1) According to the design composition, the raw materials are mixed and then pressed to obtain electrodes, which are smelted in a vacuum consumable electric arc furnace three times to obtain ingots;

[0052] (2) The alloy adopts three-fire forging process, blank forging: 1100°C, deformation amount 50%; second-fire forging: 920°C, deformation amount 50%; third-fire forging: 900°C, deformation amount 50%;

[0053] (3) Rolling process: the rolling temperature is 91...

Embodiment 3

[0059] Embodiment 3: Preparation and detection of titanium alloy material (three)

[0060] The composition ratio of the titanium alloy prepared in this example is Ti-7Al-2Sn-2Zr-3Mo-2V-2Cr-3Nb, the aluminum equivalent of the titanium alloy is 8.8, and the molybdenum equivalent is 8.67. The raw materials for titanium alloy preparation are Al-Sn50, Al-Mo80, Al-V60, Al-Nb62, electrolytic chromium, aluminum beans, zirconium sponge and grade 0 titanium sponge.

[0061] The specific preparation process is:

[0062] (1) According to the design composition, the raw materials are mixed and then pressed to obtain electrodes, which are smelted in a vacuum consumable electric arc furnace three times to obtain ingots;

[0063] (2) The alloy adopts three-fire forging process, blank forging: 1150°C, deformation amount 50%; second-fire forging: 940°C, deformation amount 50%; third-fire forging: 920°C, deformation amount 50%;

[0064] (3) Rolling process: the rolling temperature is 930° C., ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Room temperature tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com