Three-dimensional multi-layered structure cobalt-nickel-aluminum ternary metal electrocatalyst for oxygen evolution reaction as well as preparation and application methods thereof

A technology of oxygen evolution reaction and electrocatalyst, which is applied in the direction of electrodes, electrolytic components, electrolysis process, etc., can solve the problems of limited exposure of oxygen evolution active components and easy aggregation of nanoparticles, so as to increase the electrochemical active area and reduce the potential barrier , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

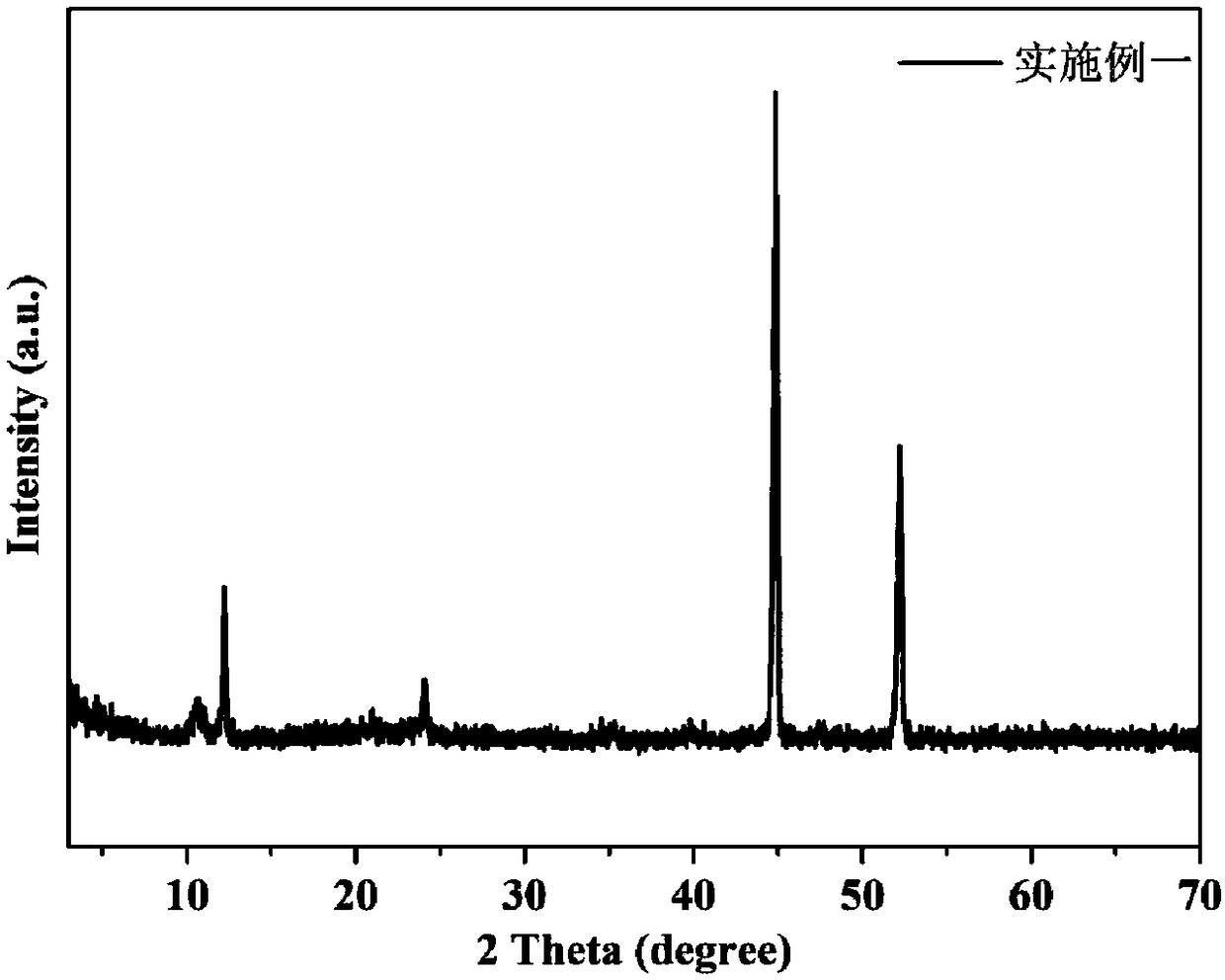

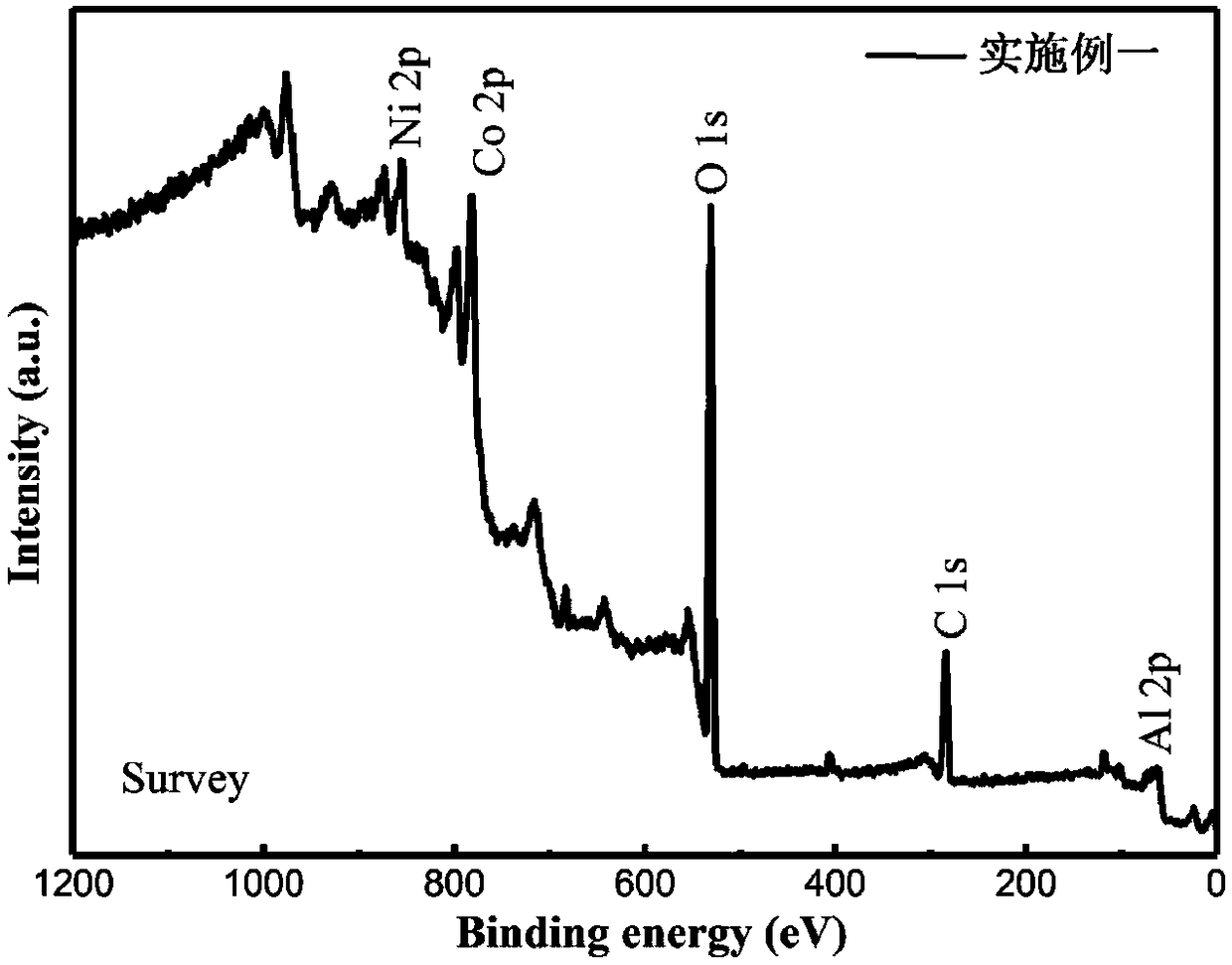

Embodiment 1

[0030] The nickel foam substrate was ultrasonically cleaned in acetone solution for 15 minutes, then transferred to 2 mol / L hydrochloric acid for ultrasonic cleaning for 5 minutes, and then transferred to ethanol solution for ultrasonic cleaning for 5 minutes, and finally the foamed nickel substrate was rinsed thoroughly with deionized water. Then put it in an oven at 80°C for drying; dissolve 0.3492g cobalt nitrate, 0.15g aluminum nitrate, 0.6006g urea and 0.296g ammonium fluoride in 80mL water, transfer to a polytetrafluoroethylene liner, and put it into a high-pressure reaction Tighten the kettle, take it out after hydrothermal reaction at 150°C for 10 hours, cool it naturally, and dry overnight at 70°C. During the entire reaction process, a cobalt-nickel-aluminum hydrotalcite nanosheet array is grown vertically on the surface of the foamed nickel substrate. Prepare 40mL methanol solution containing 0.291g cobalt nitrate methanol solution, 0.324g 2-methylimidazole methanol so...

Embodiment 2

[0034] The foamed nickel substrate was ultrasonically cleaned in acetone solution for 5 minutes, then transferred to 3 mol / L hydrochloric acid for ultrasonic cleaning for 20 minutes, and then transferred to ethanol solution for ultrasonic cleaning for 20 minutes, and finally the foamed nickel substrate was thoroughly rinsed with deionized water. Then put it in an oven at 80°C for drying; dissolve 0.1746g cobalt nitrate, 0.075g aluminum nitrate, 0.3003g urea and 0.148g ammonium fluoride in 80mL water, transfer it to a polytetrafluoroethylene liner, and load it into a high-pressure reaction Tighten the kettle, heat it in water at 180°C for 6 hours, take it out, cool it naturally, and dry overnight at 70°C. During the entire reaction process, an array of cobalt-nickel-aluminum hydrotalcite nanosheets grows vertically on the surface of the foamed nickel substrate. Prepare 40mL methanol solution containing 2.328g cobalt nitrate methanol solution, 2.592g 2-methylimidazole methanol sol...

Embodiment 3

[0037] The nickel foam substrate was ultrasonically cleaned in acetone solution for 20 minutes, then transferred to 1 mol / L hydrochloric acid for ultrasonic cleaning for 5 minutes, and then transferred to ethanol solution for ultrasonic cleaning for 20 minutes, and finally the foamed nickel substrate was rinsed thoroughly with deionized water. Then put it in an oven at 50°C for drying; dissolve 0.2328g cobalt nitrate, 0.1g aluminum nitrate, 0.4004g urea and 0.192g ammonium fluoride in 80mL water, transfer to a polytetrafluoroethylene liner, and put it into a high-pressure reaction Tighten the kettle, take it out after hydrothermal heating at 80°C for 2h, cool it naturally, and dry overnight at 70°C. During the entire reaction process, an array of cobalt-nickel-aluminum hydrotalcite nanosheets grows vertically on the surface of the foamed nickel substrate. Prepare 40mL methanol solution containing 0.582g cobalt nitrate methanol solution, 0.648g 2-methylimidazole methanol solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com