Method for comprehensive recovery treatment of zinc-containing metallurgical dust and sludge

A technology for metallurgical dust and sludge recovery and treatment, which is applied in chemical instruments and methods, improvement of process efficiency, photography process, etc., can solve the problems of slow dissolution rate of electric furnace dust, long process processing time, difficult leaching or reduction, etc. Conducive to the recovery of iron resources, the realization of green metallurgy, the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

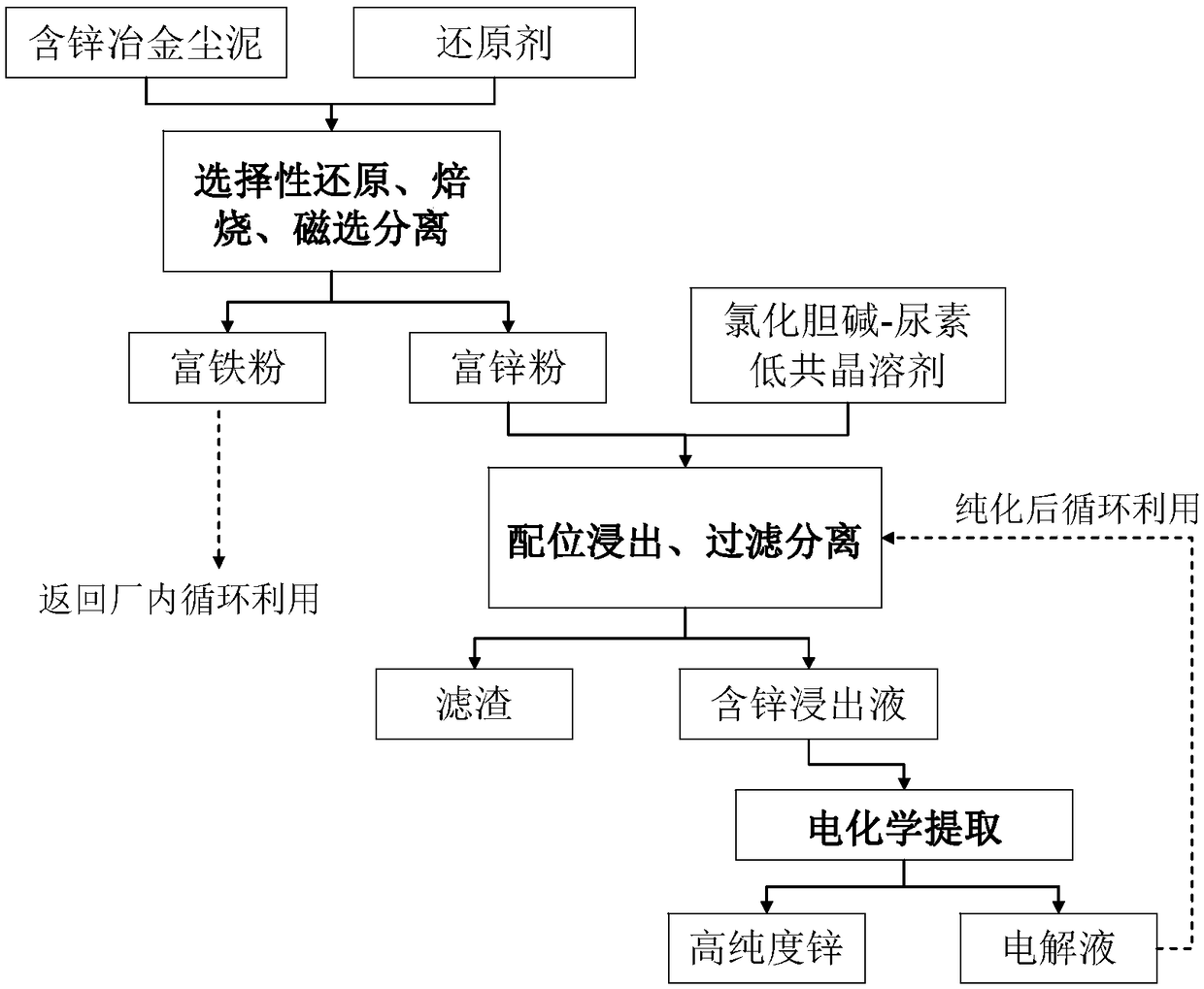

[0024] A method for comprehensive recovery and treatment of zinc-containing metallurgical dust, the process of which is as follows figure 1 Shown, including the following processes and steps:

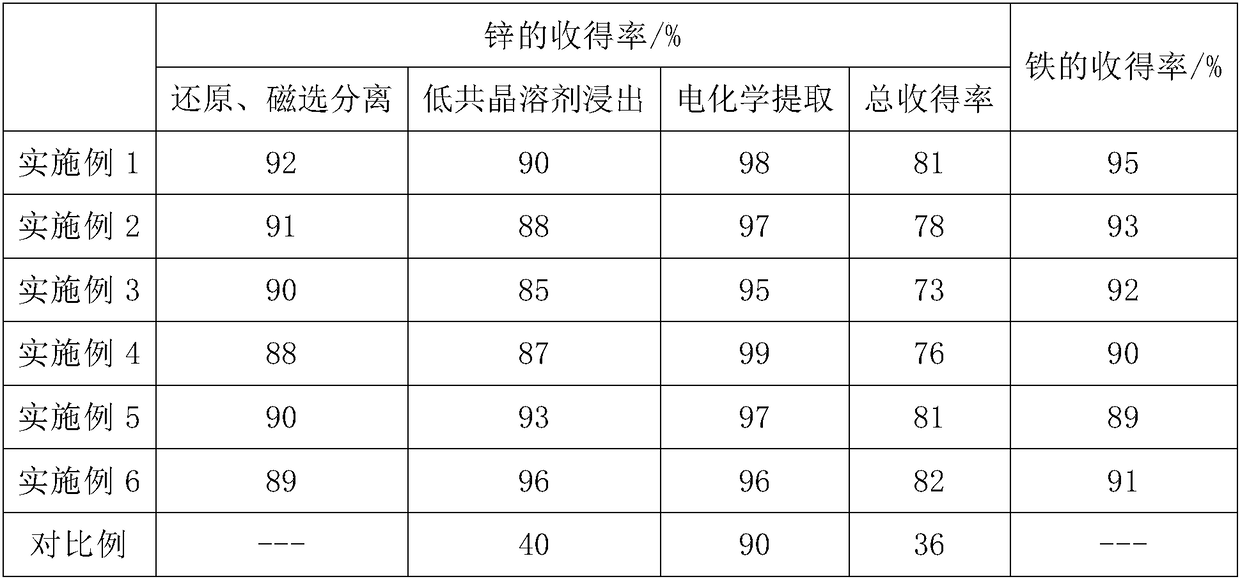

[0025] The composition of zinc-containing metallurgical dust in the present embodiment is as follows: Fe 2 o 3 (converted content of total iron) ≤ 80wt%, ZnO ≤ 15wt%, others ≤ 5wt%. Grind zinc-containing metallurgical dust to less than 75 μm, dry it, add solid reducing agent coal powder for thorough mixing, and then reduce and roast in a closed high-temperature furnace at 850°C for 1 hour. The reduced powder is cooled, crushed, ground, and magnetically separated to obtain an iron-rich powder with a TFe grade of 89.5% and a zinc-rich powder with a Zn grade of 34.2wt%. The yield of iron is 95%, and the yield of zinc The yield was 92%. The iron-rich powder is returned to the factory for direct recycling; the zinc-rich powder is added to the choline chloride-urea (molar ratio 1:2) low-e...

Embodiment 2

[0027] The composition of zinc-containing metallurgical dust in the present embodiment is as follows: Fe 2 o 3 (Content in total iron conversion) ≤ 60wt%, ZnO ≤ 25wt%, others ≤ 15wt%. Grind zinc-containing metallurgical dust to less than 75 μm, dry it, add solid reductant carbon powder for thorough mixing, and then reduce and roast in a closed high-temperature furnace at 750°C for 1.5 hours. After the reduction, the powder is cooled, crushed, ground, and magnetically separated to obtain an iron-rich powder with a TFe grade of 85.6wt% and a zinc-rich powder with a Zn grade of 45.2wt%. The yield of iron is 93%, and the yield of zinc The yield was 91%. The iron-rich powder is returned to the factory for direct recycling; the zinc-rich powder is added to the choline chloride-urea (molar ratio 1:2) low-eutectic solvent, stirred and leached at 65°C for 10 hours, and then separated by suction filtration to obtain Leachate and filter residue, the yield of zinc in the leachate is 88...

Embodiment 3

[0029] The composition of zinc-containing metallurgical dust in the present embodiment is as follows: Fe 2 o 3(converted content of total iron) ≤ 75wt%, ZnO ≤ 15wt%, others ≤ 10wt%. Grind the zinc-containing metallurgical dust to less than 75μm, dry it, and then put it into a closed high-temperature furnace. The CO gas with a gas volume of 30% was used for reduction roasting at 800° C. for 2 hours. After the reduction, the powder is cooled, crushed, ground, and magnetically separated to obtain an iron-rich powder with a TFe grade of 82.6wt% and a zinc-rich powder with a Zn grade of 29.2wt%. The yield of iron is 92%, and the yield of zinc The yield was 90%. The iron-rich powder is returned to the factory for direct recycling; the zinc-rich powder is added to choline chloride-urea (molar ratio 1:2) low-eutectic solvent, stirred and leached at 75°C for 30 hours, and then separated by suction filtration to obtain Leachate and filter residue, the yield of zinc in the leachate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com