A kind of preparation method and application of nickel matrix/nickel hydroxide composite electrode

A composite electrode and substrate technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of complex process, low degradation efficiency, high energy consumption, etc., and achieve strong application prospects, The effect of low energy consumption and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a preparation method and application of a nickel matrix / nickel hydroxide composite electrode. The specific steps of the preparation method are as follows:

[0022] (1) Measure a nickel substrate of a certain quality, ultrasonically clean it with acetone, ethanol, and high-purity water in sequence, place it in an oven for drying, and put it into a polytetrafluoroethylene reactor; the temperature of the oven is 60°C.

[0023] (2) Measure excessive hydrogen peroxide solution, add hydrogen peroxide solution in step (1) reactor, the reactor is placed in the oven to keep warm, take out the reactor, cool to room temperature, take out the solid product in the reactor; The temperature of the oven is 100° C. to 180° C., and the holding time is 1 to 8 hours.

[0024] (3) The solid product obtained in step (2) is ultrasonically cleaned in high-purity water, and then dried in an oven to obtain a nickel matrix / nickel hydroxide composite electrode material; the ...

Embodiment 1

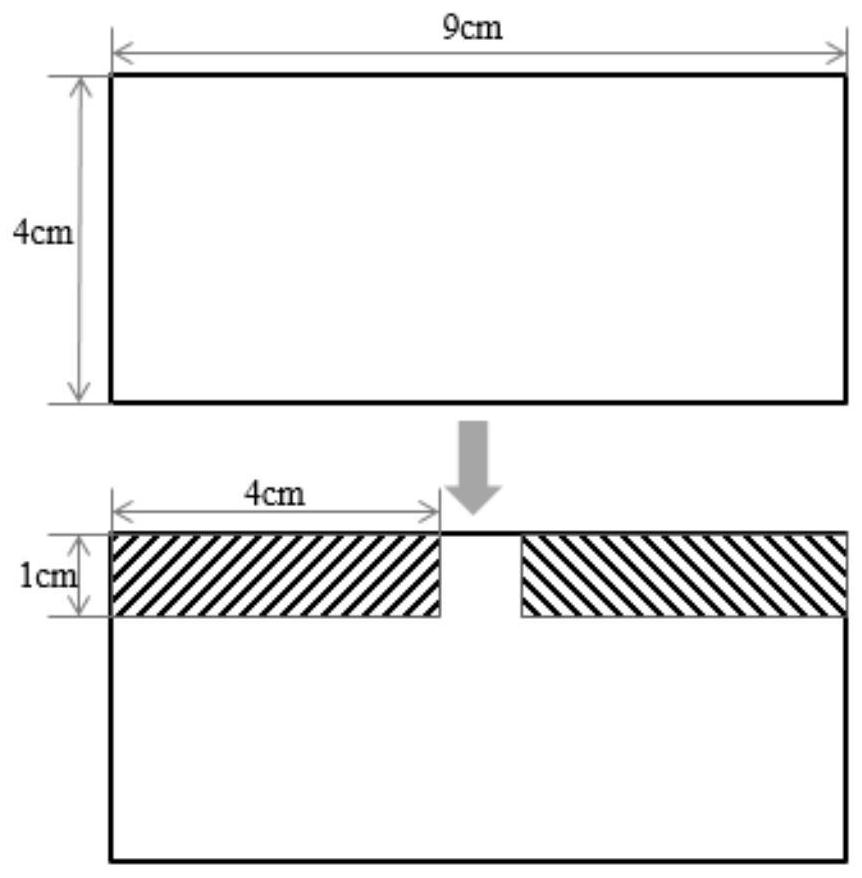

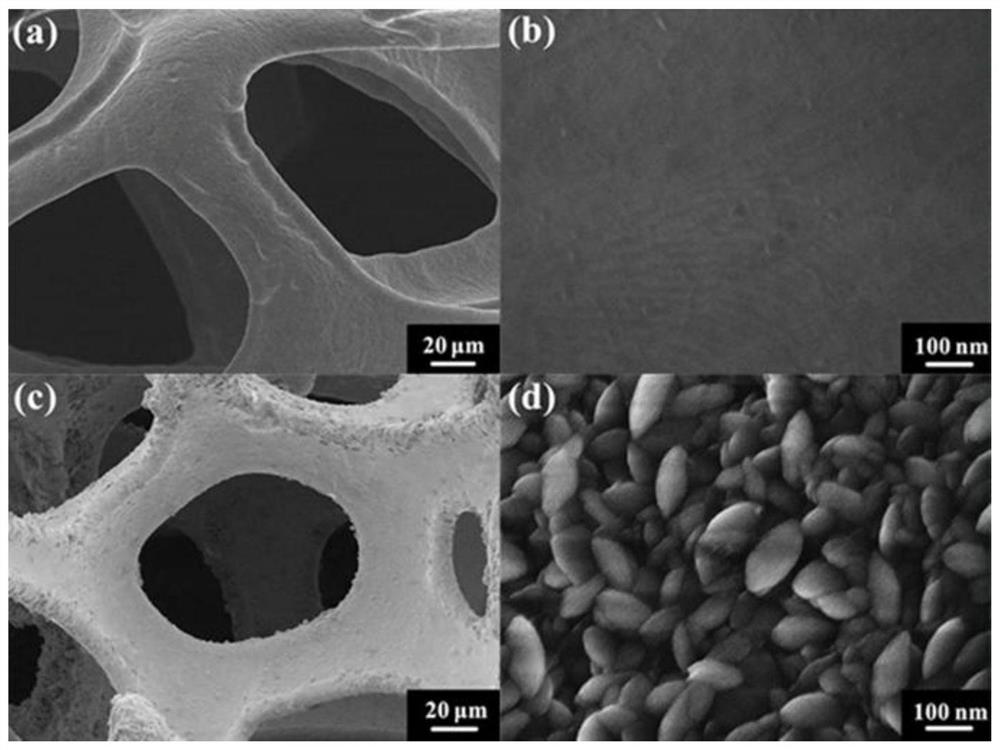

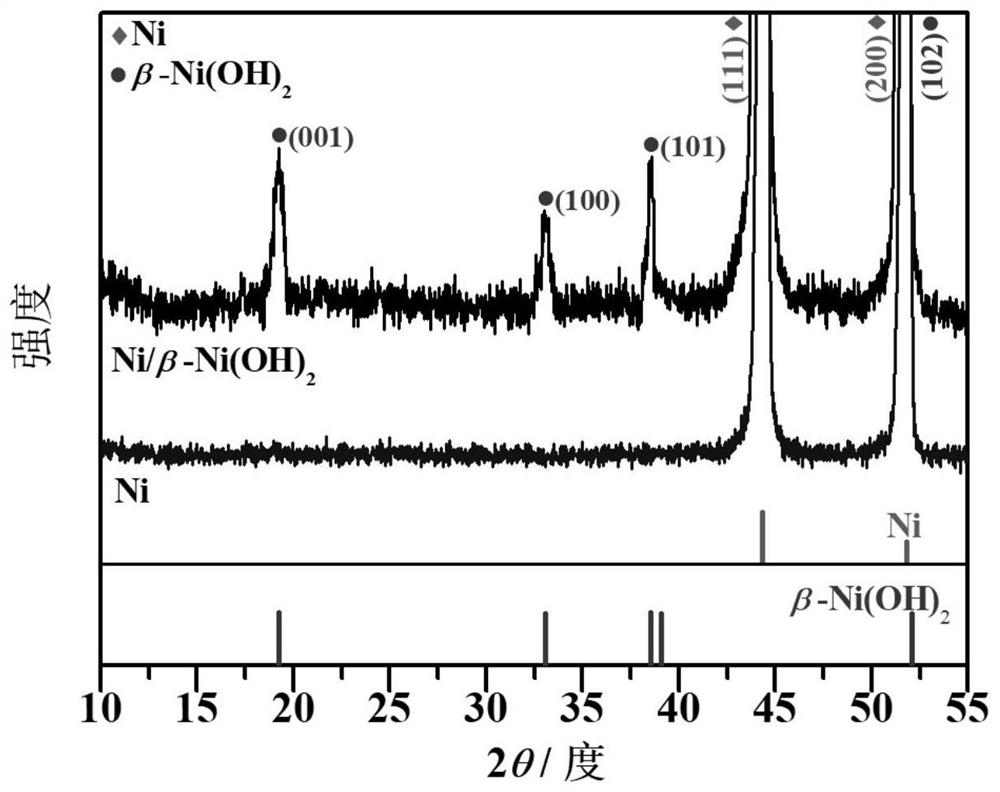

[0029] The nickel substrate is nickel foam with a porosity of 110ppi and a thickness of 1.7mm. figure 1 The schematic in the clipping nickel foam. Such as figure 1 The upper picture shown above is the initially cut rectangular nickel foam with an area of 4cm×9cm, and then cut off the shaded part (two pieces of 1cm×4cm) as shown in the picture below to obtain the desired shape of nickel foam (corresponding to figure 1 The white part below), rolled into a cylinder from left to right to ensure a larger area when placed in a reactor for growth, ultrasonically cleaned with acetone, ethanol, and high-purity water for 10 minutes, and dried in an oven at 60°C. Weighing and obtaining quality is 1.4g nickel substrate, then puts into polytetrafluoroethylene reactor; Theoretically, 1.4g nickel is completely oxidized to divalent nickel and needs the volume of the hydrogen peroxide solution of 30% (mass percentage concentration) at least 2.4ml, the present embodiment measures 35ml mass ...

Embodiment 2

[0035] A nickel foil with a thickness of 0.8mm was selected as the nickel substrate. The sample preparation and clipping methods were the same as in Example 1. The cylindrical nickel foil sample was clipped, ultrasonically cleaned with acetone, ethanol, and high-purity water for 10 minutes, and placed in an oven at 60°C. Internal drying, weighed to obtain a mass of 1.0g, and then put it into a polytetrafluoroethylene reactor; in theory, completely oxidizing 1.0g of nickel to divalent nickel requires a volume of at least 5.2ml of 10wt.% hydrogen peroxide solution , measure 35ml of hydrogen peroxide with a mass concentration of 10% and transfer it to the reaction kettle to ensure that the hydrogen peroxide solution is excessive and completely submerge the nickel substrate. to room temperature; the obtained solid product was ultrasonically cleaned in high-purity water for 10 minutes, and dried in an oven at 60°C to obtain nickel foil / nickel hydroxide (Ni / Ni(OH) 2 ) composite elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com