Preparation method of polylactic acid based hydrophobic thin film

A hydrophobic film, polylactic acid-based technology, which is applied in the field of preparation of polylactic acid-based hydrophobic films, can solve the problems of expensive production equipment, non-biodegradability, and non-hydrophobicity of the film, and achieves easy control of process conditions and simple and efficient preparation method. , the effect of large practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

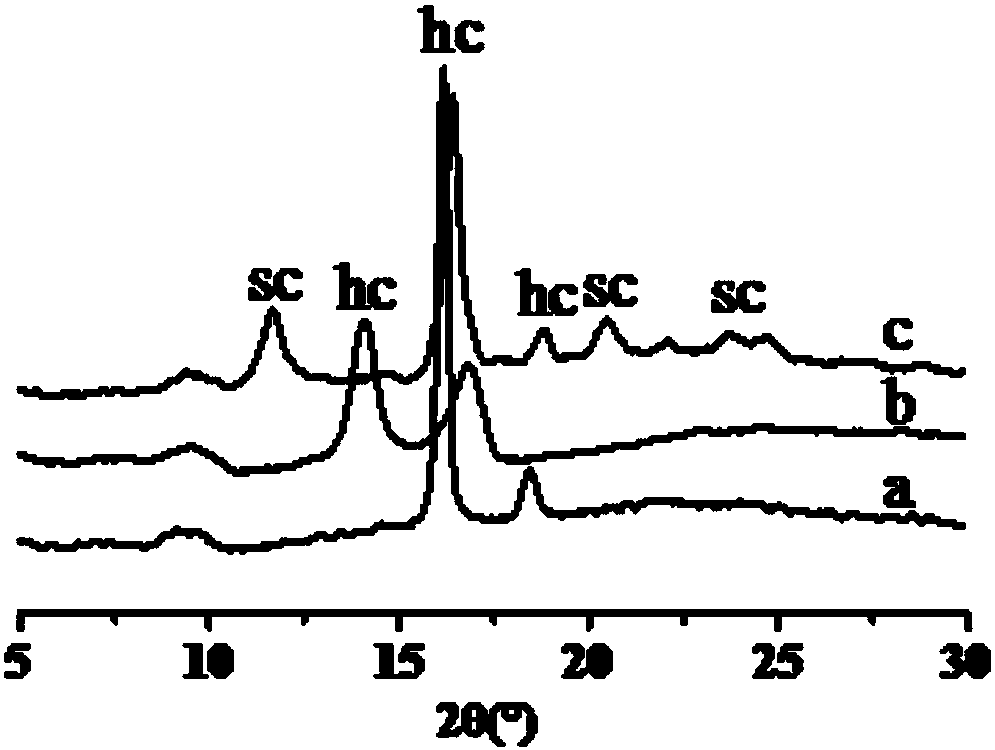

[0063] The preparation method of the polylactic acid-based hydrophobic film of the present invention firstly synthesizes a triblock copolymer (PDLA-PDMS-PDLA) of left-handed polylactic acid (PLLA), right-handed polylactic acid and polydimethylsiloxane. Dissolve PLLA in an organic solvent, spin-coat it on a glass slide to prepare a PLLA polymer film, and after a certain annealing treatment, then spin-coat the organic solvent of the triblock copolymer PDLA-PDMS-PDLA on the PLLA polymer film, After a certain annealing treatment, the polylactic acid-based hydrophobic film was prepared.

[0064] The preparation method of the polylactic acid-based hydrophobic film of the present invention adopts the isomer PDLA of the PLLA polymer and PDMS with certain hydrophobicity to form a three-block copolymer PDLA-PDMS-PDLA, and then the three-block copolymer PDLA -PDMS-PDLA film is prepared on the surface of PLLA polymer film substrate with relatively high molecular weight. The polylactic ac...

Embodiment 1

[0067] Synthesis of PLLA polymer

[0068] Purification of L-lactide: Purify the raw material L-lactide 3 times with ethyl acetate, mix 200g of L-lactide with ethyl acetate with a mass ratio of 75%, and make L-lactide in a water bath at 60°C. -Lactide is completely dissolved, cooled at room temperature and placed in the refrigerator overnight, and the ethyl acetate that has dissolved impurities is suction-filtered, purified three times according to the above method, and finally the purified L-lactide is placed in a cold trap device to vacuum for 24 hours , to remove all solvent.

[0069] Weigh the materials in the glove box, add 10g L-lactide, 260ul methyl lactate, 1ml stannous octoate, and 30ml solvent toluene into the three-necked flask, take it out from the glove box and place it in an oil bath at 130°C for reaction 3 ~5h. Add 100ml of anhydrous diethyl ether stored in the refrigerator for precipitation, and finally place the reaction solution in a cold trap device to vacu...

Embodiment 2

[0085] Synthesis of PLLA polymer

[0086] Purification of L-lactide: Purify the raw material L-lactide 3 times with ethyl acetate, mix 200g of L-lactide with ethyl acetate with a mass ratio of 75%, and make L-lactide in a water bath at 60°C. -Lactide is completely dissolved, cooled at room temperature and placed in the refrigerator overnight, and the ethyl acetate that has dissolved impurities is suction-filtered, purified three times according to the above method, and finally the purified L-lactide is placed in a cold trap device to vacuum for 24 hours , to remove all solvent.

[0087] Weigh the materials in the glove box, add 10g L-lactide, 260ul methyl lactate, 1ml stannous octoate, and 30ml solvent toluene into the three-necked flask, take it out from the glove box and place it in an oil bath at 130°C for reaction 3 ~5h. Add 100ml of anhydrous diethyl ether stored in the refrigerator for precipitation, and finally place the reaction solution in a cold trap device to vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com