Anti-radiation water-based paint

A water-based coating, radiation protection technology, applied in the direction of coating, can solve the problem of not being able to play radiation protection, and achieve the effects of excellent scrub resistance, good film-forming performance and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

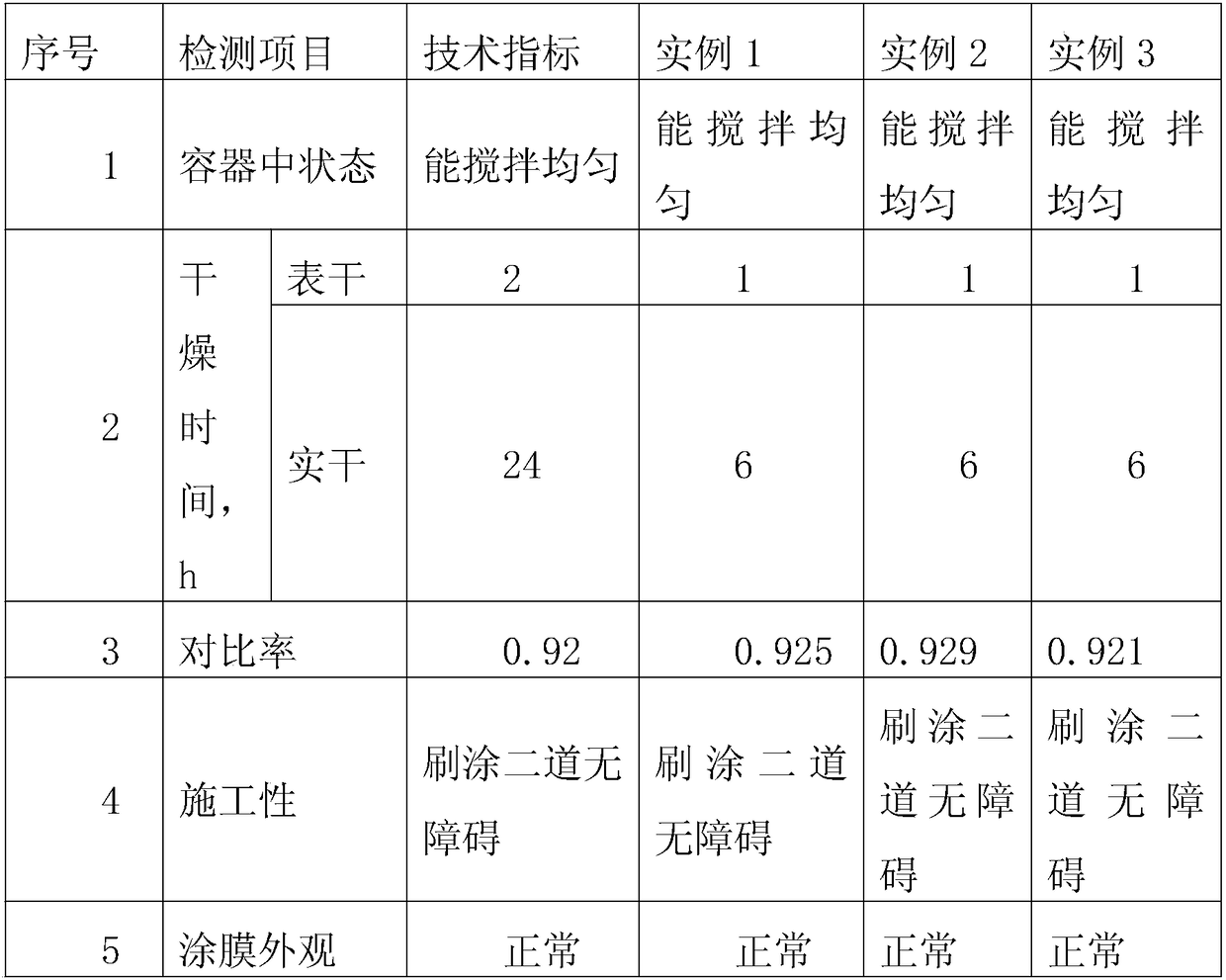

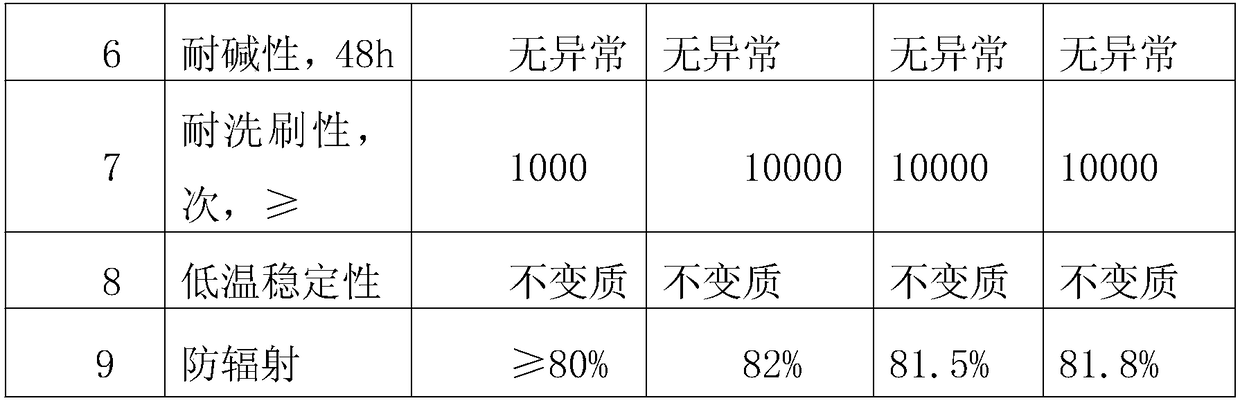

Examples

Embodiment 1

[0035] A kind of anti-radiation water-based paint, according to parts by weight, the components included are: 60 parts of water-based anti-radiation emulsion, 15 parts of deionized water, 0.3 part of French Sipson chemical S150, 0.3 part of wetting agent, Nopco SN- 0.2 parts of 154 silica-type defoamer, 0.4 parts of DOW731A polyphosphate, 0.3 parts of Digao TEGO450 leveling agent, 10 parts of antifreeze, 20 parts of Eastman TEXANOL film-forming aids, 25 parts of pigments and fillers (including titanium dioxide 15 parts, 10 parts of barium sulfate powder), 5 parts of diatomaceous earth and 5 parts of TT-935 thickener.

[0036] Its preparation method is as follows:

[0037] (1) Add deionized water to reactor A, heat up to 80°C, stir at a speed of 100-200rpm, add water-based odor-cleaning emulsion, the pressure of the reactor is 7.8MPa, and slowly add flavanol under the catalyst of nickel, Through the polycondensation reaction, the water-based clean taste radiation protection em...

Embodiment 2

[0042] A kind of anti-radiation water-based paint of the present embodiment 2: by weight, the components included are: 55 parts of water-based anti-radiation emulsion, 0.3 parts of wetting agent, 20 parts of deionized water, 0.3 part of French Sipson chemical S150, 0.4 parts of BASF A10 water-based mineral oil defoamer, 0.3 parts of DOW731A polyphosphate, 0.5 parts of Tego TEGO450 leveling agent, 12 parts of antifreeze, 17 parts of Eastman TEXANOL film-forming aid, 30 parts of pigments and fillers (of which Long 15 parts of python R-996 titanium dioxide, 15 parts of barium sulfate powder), 5 parts of diatomaceous earth and hydroxyethyl cellulose are HS 30000YP2 of Shin-Etsu Japan.

[0043] Its preparation method is as follows:

[0044] (1), 1.1, add deionized water to reaction tank A, heat up to 50°C, stir at a speed of 100-200rpm, slowly add Bard Fujing emulsion 959W, and the pressure of the reaction tank is 7.8MPa;

[0045] 1.2. By extracting one or more of tea polyphenols (a...

Embodiment 3

[0051] A kind of anti-radiation water-based paint of this embodiment 3: by weight, the components included are: 50 parts of water-based anti-radiation emulsion, 0.15 parts of wetting agent, 10 parts of deionized water, 0.1 part of French Sipson Chemical S150, 0.2 parts of BASF A10 water-based mineral oil defoamer, 0.2 parts of DOW731A polyphosphate, 0.3 parts of TEGO450 leveling agent, 10 parts of antifreeze, 15 parts of Eastman TEXANOL film-forming aid, 35 parts of pigments and fillers (wherein Lomon R-996 titanium dioxide 15 parts, barium sulfate powder 20 parts), diatomaceous earth 3 parts, Dow TT935 thickener 5 parts.

[0052] The novel anti-radiation coating of present embodiment 3, preparation method is as follows:

[0053] (1), 1.1. Add deionized water to reaction tank A, raise the temperature to 50°C, stir at a speed of 100-200rpm, slowly add Bard Fujing Emulsion 959W, and the pressure of the reaction tank is 7.8MPa.

[0054] 1.2. By extracting one or more of tea poly...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap