Method for regenerating mine filling wastewater

A mine filling and wastewater technology, applied in mining wastewater treatment, chemical instruments and methods, water pollutants, etc., can solve the problems of high operating cost, need for evaporation and concentration, large investment, etc., and achieve the effect of low cost and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

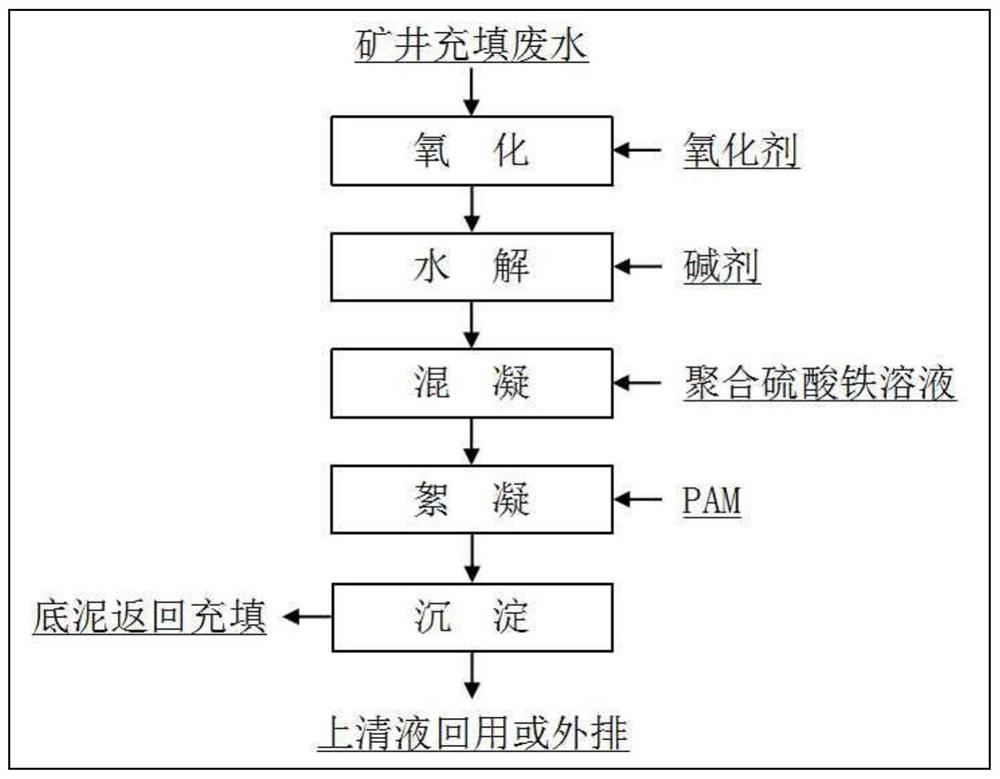

Method used

Image

Examples

Embodiment 1

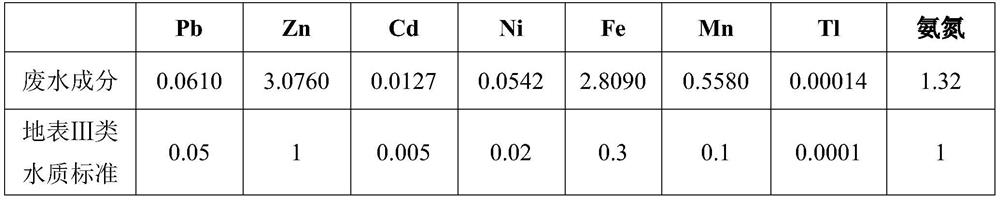

[0031] Table 1 Mine filling wastewater composition (mg / L)

[0032]

[0033] Take 1000mL of mine filling wastewater into a beaker, add 0.1g of trichloroisocyanuric acid, potential +710mv, stir for 5 minutes, add lime 0.2g, adjust the pH of the solution to 10.24, stir for 10 minutes, then add 30% polyferric sulfate solution 0.5mL, adjust the pH of the solution to 6.46, stir and react for 10 minutes, add 0.1% polyacrylamide solution 0.5mL, reduce the stirring speed, stir for 3 minutes and let it settle, the supernatant is the regeneration solution, and the regeneration solution is tested analyze. From the analysis results of the regeneration fluid in Table 2, it can be seen that the regeneration method of mine filling wastewater has a good effect, and all indicators after treatment can reach the surface water quality standard of Class III, the process is simple, and the effect is superior.

[0034] Table 2 Analysis results of regeneration solution (mg / L)

[0035]

Embodiment 2

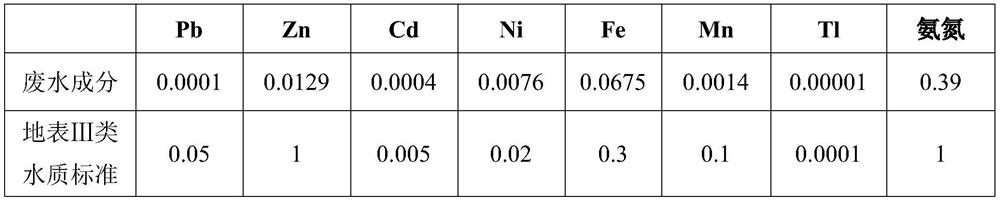

[0037] Table 3 Mine Filling Wastewater Components (mg / L)

[0038]

[0039] Take 1000mL of mine filling wastewater into a beaker, add 0.05g of sodium dichloroisocyanurate, the potential is +622mv, stir for 5 minutes, add caustic soda 0.2g, adjust the pH of the solution to 10.07, add 30% polymeric sulfuric acid after stirring for 10 minutes 0.4mL of iron solution, adjust the pH of the solution to 7.80, stir and react for 10 minutes, add 0.5mL of 0.1% polyacrylamide solution, reduce the stirring speed, let it settle after stirring for 5 minutes, the supernatant is the regeneration solution, and the regeneration solution Perform assay analysis. From the analysis results of the regeneration fluid in Table 4, it can be seen that the regeneration method of mine filling wastewater has a good effect, and all indicators after treatment can reach the surface water quality standard of Class III, the process is simple, and the effect is superior.

[0040] Table 4 Analysis results of re...

Embodiment 3

[0043] Table 5 Mine Filling Wastewater Components (mg / L)

[0044]

[0045]Take 1000mL of mine filling wastewater into a beaker, add 0.08g of sodium dichloroisocyanurate, potential +683mv, stir for 5 minutes, add lime 0.3g, adjust the pH of the solution to 10.33, stir for 10 minutes, then add 30% polyferric sulfate Solution 0.4mL, adjust the pH of the solution to 7.93, stir and react for 10 minutes, add 0.1% polyacrylamide solution 0.5mL, reduce the stirring speed, stir for 5 minutes and let it settle, the supernatant is the regeneration solution, and the regeneration solution is Laboratory analysis. From the analysis results of the regeneration fluid in Table 6, it can be seen that the regeneration method of mine filling wastewater has a good effect, and all indicators after treatment can reach the surface water quality standard of Class III. The process is simple and the effect is superior.

[0046] Table 6 Analysis results of regeneration solution (mg / L)

[0047]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap