A boron-containing low-carbon steel oxide film layer and preparation method thereof

A technology of oxide film layer and low carbon steel, which is applied in the direction of anodic oxidation, coating, electrolytic inorganic material coating, etc., can solve the problem that magnesium alloy can replace alloy special steel, coating strength, wear resistance and corrosion resistance can not meet the demand , complex process and other issues, to achieve the effect of suppressing the electronic flow circuit, avoiding galvanic corrosion, and having a dense and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

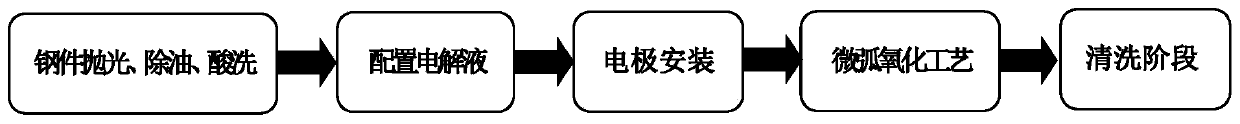

[0028] The invention provides a method for preparing a boron-containing low-carbon steel oxide film layer, comprising the following steps:

[0029] Using boron-containing low-carbon steel as an anode, micro-arc oxidation is carried out in an electrolyte to obtain an oxide film layer of boron-containing low-carbon steel; the electrolyte includes 5-25 g / L of sodium metaaluminate and 2-10 g of sodium dihydrogen phosphate / L, sodium carbonate 2~15g / L and glycerol 2~8g / L.

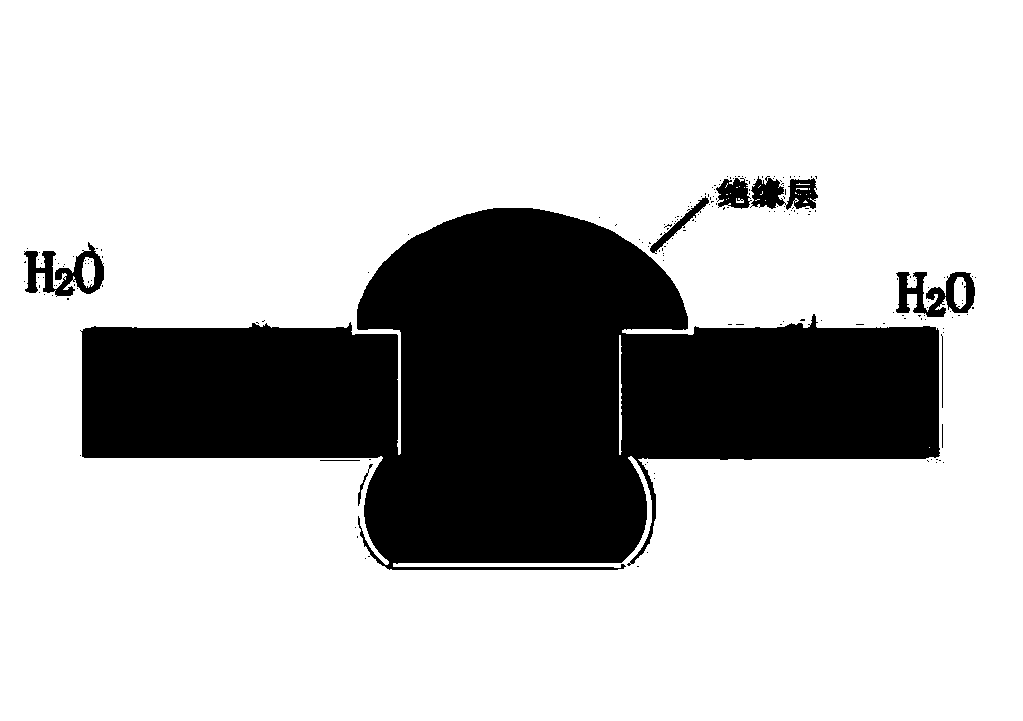

[0030] In the invention, the boron-containing low-carbon steel is used as an anode, and micro-arc oxidation is carried out in an electrolytic solution to obtain an oxide film layer of the boron-containing low-carbon steel. In the present invention, the model of the boron-containing low-carbon steel is preferably 10B21. The boron-containing low-carbon steel selected in the present invention is different from non-ferrous metals such as Ti, Al, Mg in micro-arc oxidation to form their own oxide ceramic coatings, con...

Embodiment 1

[0058] 1) Pretreatment

[0059] After the crude 10B21 boron-containing low-carbon steel is mechanically polished, it is degreased in a sodium hydroxide solution at a temperature of 70°C, and then pickled in a mixed solution of hydrochloric acid and sulfuric acid (volume ratio: 3:1) for 3 minutes. The temperature is 70°C, and finally the pickled product is put into flowing clear water to remove the pickling solution involved in the surface to obtain 10B21 boron-containing low-carbon steel.

[0060] 2) Configure the electrolyte system; sodium metaaluminate 5g / L, sodium dihydrogen phosphate 2g / L, sodium carbonate 2g / L, glycerin 2g / L. Stir and dissolve in water according to the above ratio, and keep the pH value of the electrolyte solution at 8-12.

[0061] 3) Electrode installation: clamp the 10B21 boron-containing low-carbon steel into the electrolyte; select a hanging fixture with good conductivity, clamp the 10B21 boron-containing low-carbon steel to be treated by the micro-a...

Embodiment 2

[0065] 1) Pretreatment

[0066]After the crude 10B21 boron-containing low-carbon steel is mechanically polished, it is degreased in a sodium hydroxide solution at a temperature of 90°C, and then pickled in a mixed solution of hydrochloric acid and sulfuric acid (volume ratio: 3:1) for 20 minutes. The temperature is 30°C, and finally the pickled product is put into flowing clear water to remove the pickling solution involved in the surface to obtain 10B21 boron-containing low-carbon steel.

[0067] 2) Configure the electrolyte system; sodium metaaluminate 25g / L, sodium dihydrogen phosphate 10g / L, sodium carbonate 15g / L, glycerol 8g / L. Stir and dissolve in water according to the above ratio, and keep the pH value of the electrolyte solution at 8-12.

[0068] 3) Electrode installation: clamp the 10B21 boron-containing low-carbon steel into the electrolyte; select a hanging fixture with good conductivity, clamp the 10B21 boron-containing low-carbon steel to be treated by the micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com