Colored ceramic body capable of enhancing coloring performance

A technology of performance and ceramic blanks, applied in the field of colored ceramic blanks, can solve the problems of pigment color change, oxidative peeling, difficult coloring, etc., and achieve the effects of enhanced coloring rate, long maintenance life and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

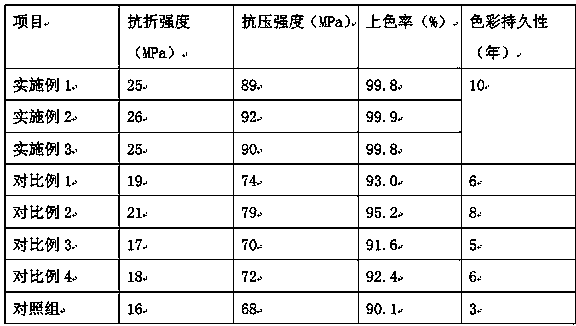

Examples

Embodiment 1

[0019] A colored ceramic billet capable of enhancing the coloring performance is made of the following components in parts by weight: 100 parts of black soil, 25 parts of fly ash, 4.5 parts of ammonium dihydrogen phosphate, 3.0 parts of magnesium oxide, 1.0 parts of sodium silicate, 0.4 parts of hydroxypropyl methylcellulose, 8 parts of sucrose solution, 0.3 parts of calcium nitrite rust inhibitor, 80 parts of absolute ethanol, 2.0 parts of triethanolamine sodium oleate, 40 parts of boric acid aqueous solution, 55 parts of deionized water, including The following steps:

[0020] (1) Put the black soil and fly ash in absolute ethanol, heat to 50°C, stir at 400 rpm for 30 minutes, then add triethanolamine sodium oleate and boric acid aqueous solution, and continue to stir at 900 rpm Stir for 45 minutes, seal and maintain at 40°C for 2 days, and place the obtained mixed slurry in a rotary evaporator to evaporate ethanol;

[0021] (2) Put the evaporated black soil mixture in deio...

Embodiment 2

[0029] A colored ceramic blank capable of enhancing the coloring performance is made of the following components in parts by weight: 105 parts of black soil, 30 parts of fly ash, 4.8 parts of ammonium dihydrogen phosphate, 3.3 parts of magnesium oxide, 1.2 parts of sodium silicate, 0.45 parts of hydroxypropyl methylcellulose, 9 parts of sucrose solution, 0.35 parts of calcium nitrite rust inhibitor, 85 parts of absolute ethanol, 2.5 parts of triethanolamine sodium oleate, 45 parts of boric acid aqueous solution, 60 parts of deionized water, including The following steps:

[0030] (1) Put black soil and fly ash in absolute ethanol, heat to 55°C, stir at 450 rpm for 35 minutes, then add triethanolamine sodium oleate and boric acid aqueous solution, continue to stir at 950 rpm Stir for 50 minutes, seal and maintain at 45°C for 2 days, and place the obtained mixed slurry in a rotary evaporator to evaporate ethanol;

[0031] (2) Put the evaporated black soil mixture in deionized w...

Embodiment 3

[0039] A colored ceramic blank capable of enhancing the coloring performance is made of the following components in parts by weight: 110 parts of black soil, 35 parts of fly ash, 5.0 parts of ammonium dihydrogen phosphate, 3.5 parts of magnesium oxide, 1.5 parts of sodium silicate, 0.5 parts of hydroxypropyl methylcellulose, 10 parts of sucrose solution, 0.4 parts of calcium nitrite rust inhibitor, 90 parts of absolute ethanol, 3.0 parts of triethanolamine sodium oleate, 50 parts of boric acid aqueous solution, 65 parts of deionized water, including The following steps:

[0040] (1) Put black soil and fly ash in absolute ethanol, heat to 60°C, stir at 500 rpm for 40 minutes, then add triethanolamine sodium oleate and boric acid aqueous solution, and continue to stir at 1000 rpm Stir for 55 minutes, seal and maintain at 50°C for 3 days, and place the obtained mixed slurry in a rotary evaporator to evaporate ethanol;

[0041](2) Put the evaporated black soil mixture in deionize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com