Preparation method of alpha-trifluoromethylthio substituted acetophenone compound

A technology of trifluoromethylthio and acetophenone, which is applied in the preparation of thioether, the formation/introduction of thiol/thioether, organic chemistry, etc. , the use of expensive and other problems, to achieve the effect of simple and convenient preparation method, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The present invention is a kind of preparation method of α-trifluoromethylthio substituted acetophenone compound, and the steps comprise:

[0061] Aryl methyl ketone as substrate, sodium trifluoromethanesulfinate as trifluoromethylthio reagent, triphosgene as reaction additive, pyridine as catalyst, dichloroethane as solvent, nitrogen protection mode, 60°C Stir for 12 hours, TLC tracking reaction, after the reaction is fully completed, column chromatography separation to obtain α-trifluoromethylthio substituted acetophenone products, the yield is between 61-85%, its reaction formula is as follows (1):

[0062]

[0063] Wherein, the proportion of aryl methyl ketone, sodium trifluoromethanesulfinate and triphosgene is 1:1.5:1 according to the molar concentration.

[0064] The outstanding innovation of the method of the present invention is that only cheap and green triphosgene is used as a reaction additive and pyridine is used as a catalyst, avoiding the use of trans...

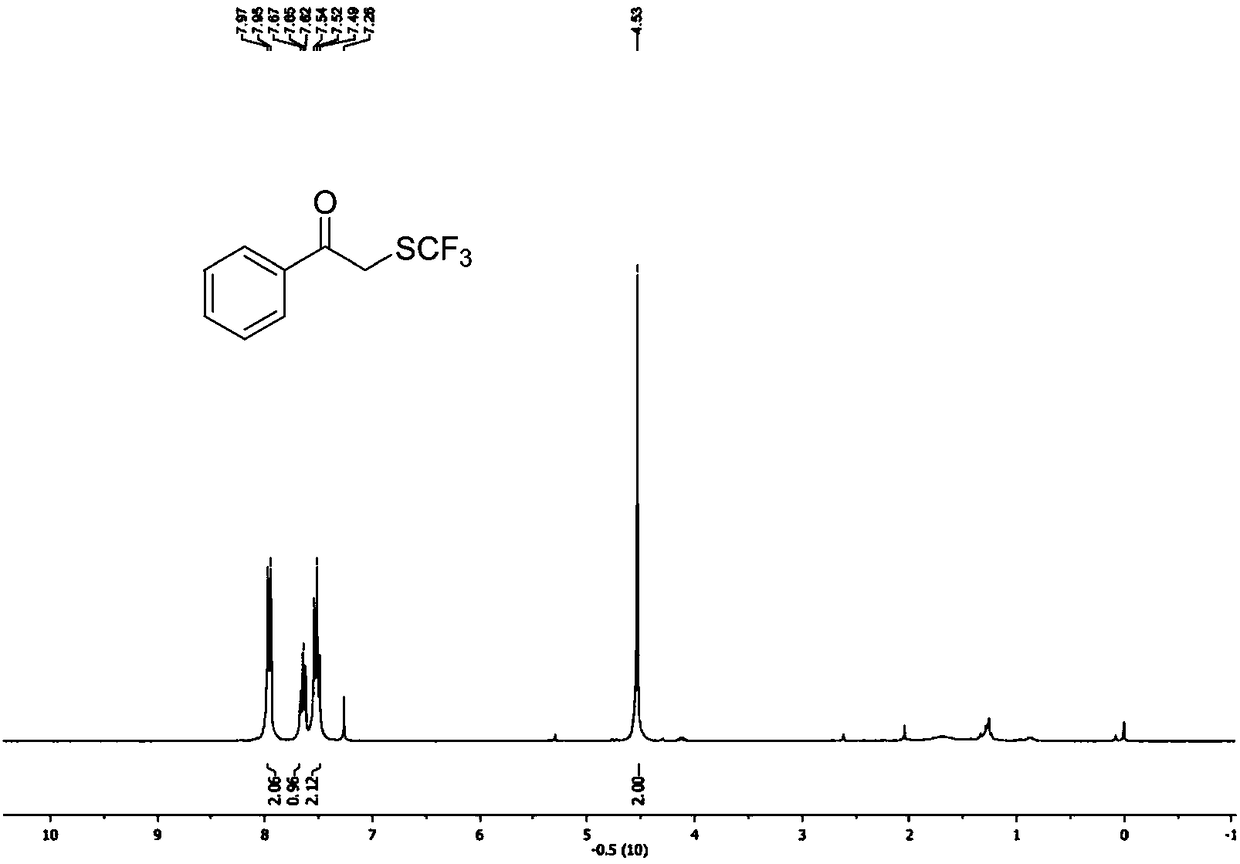

Embodiment 1

[0066] The preparation method of α-trifluoromethylthioacetophenone, its synthetic route is as follows formula (3), carries out according to the following steps:

[0067]

[0068] (1) Add 1.0 mmol of acetophenone, 1.5 mmol of sodium trifluoromethanesulfinate, 1.0 mmol of triphosgene, and 0.1 mmol of pyridine into 3 mL of DCE, under nitrogen protection, and react at 60° C. for 12 hours.

[0069] (2) After the reaction was completed, 5 mL of 5% HCl aqueous solution was added to quench the reaction. Extracted twice with ethyl acetate (10 mL×2), washed once with saturated brine, and evaporated under reduced pressure to remove ethyl acetate. The oily target product was obtained by column chromatography with a yield of 82%.

[0070] The NMR data are as follows:

[0071] Such as figure 1 as shown, 1 H NMR (400MHz, CDCl 3 ):δ=8.08-7.91(m,2H),7.67(t,J=7.3Hz,1H),7.53(t,J=7.9Hz,2H),4.54(s,2H).

[0072] Such as figure 2 as shown, 13 C NMR (101MHz, CDCl 3 ): δ=192.0(s), 134.7(s...

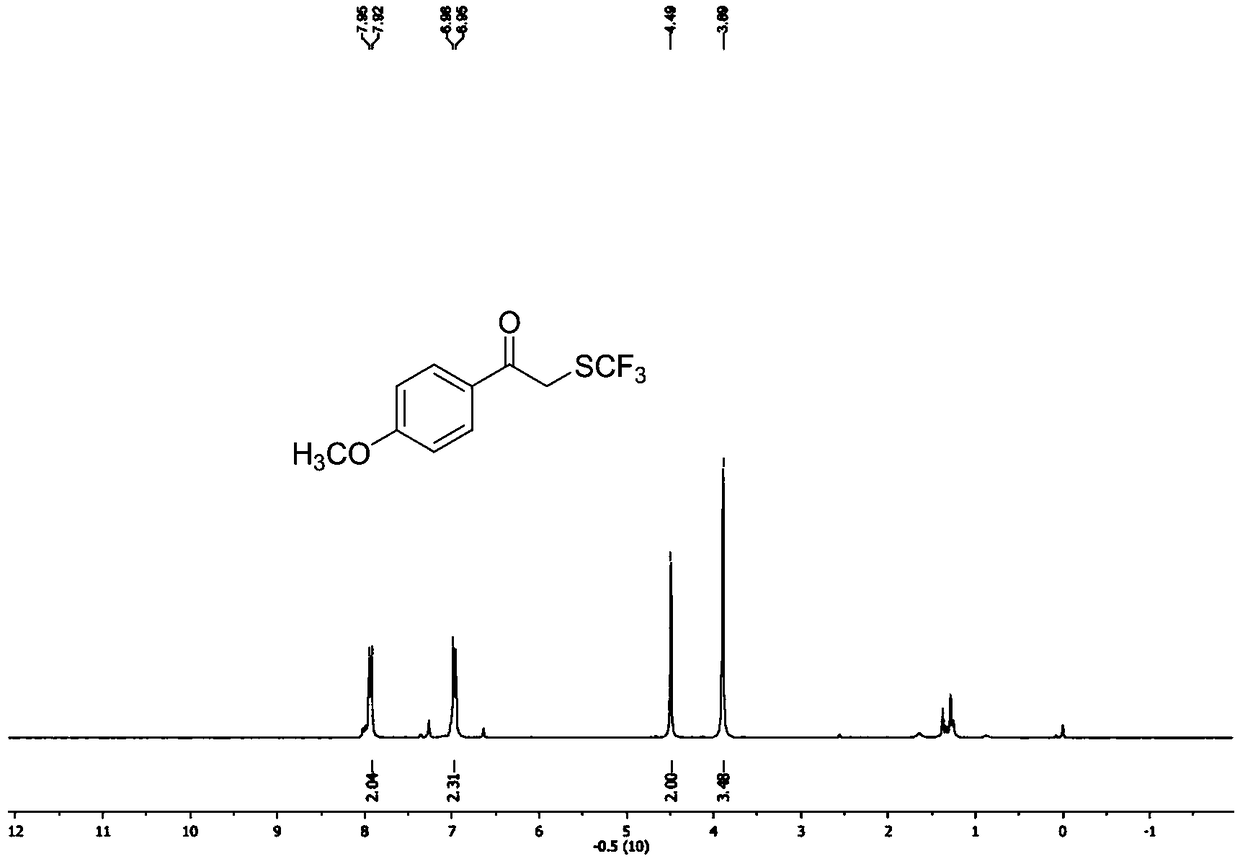

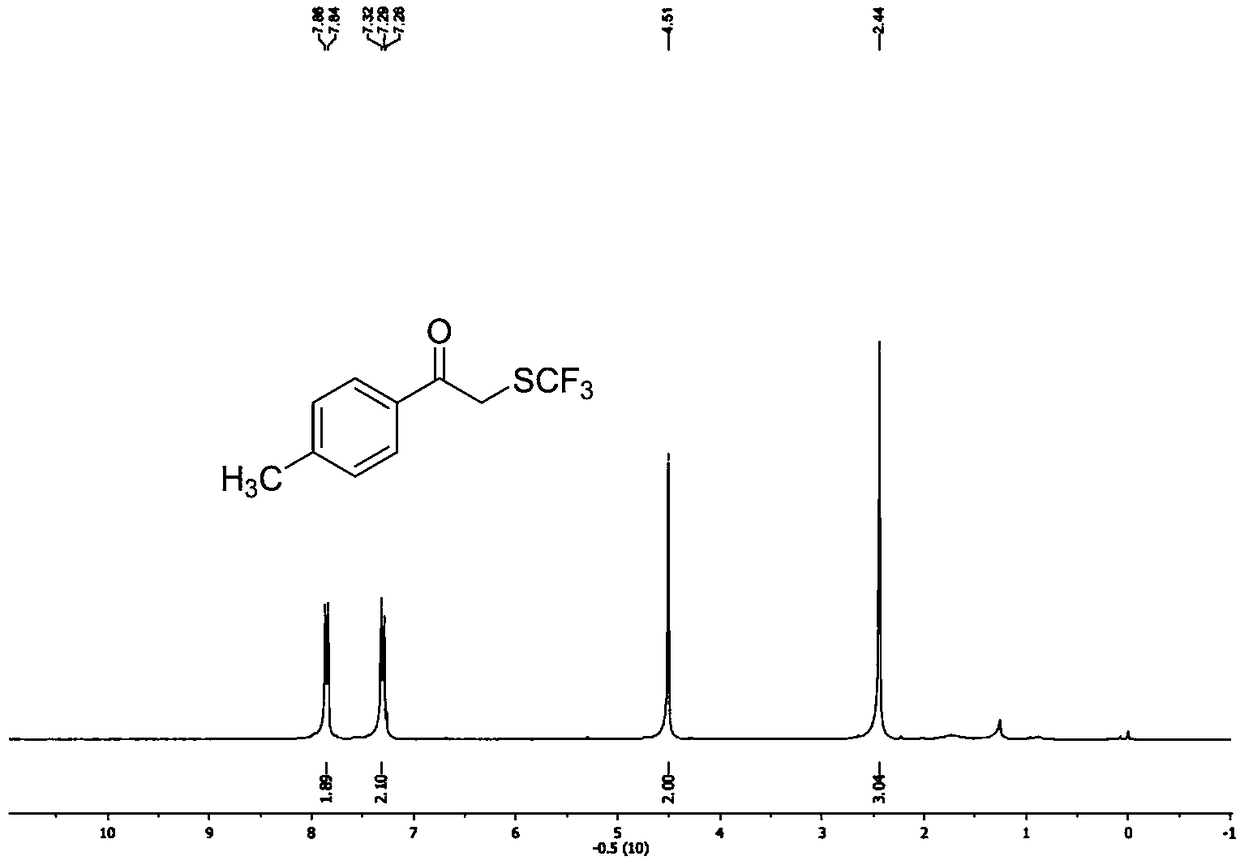

Embodiment 2

[0076] The preparation method of α-trifluoromethylthio-4-methylacetophenone, its synthetic route is as follows formula (4), carries out according to the following steps:

[0077]

[0078] (1) Add 1.0mmol of 4-methylacetophenone, 1.5mmol of sodium trifluoromethanesulfinate, 1.0mmol of triphosgene, and 0.1mmol of pyridine into 3mL of DCE, under nitrogen protection, and react at 60°C for 12 hours .

[0079] (2) After the reaction was completed, 5 mL of 5% HCl aqueous solution was added to quench the reaction. Extracted twice with ethyl acetate (10 mL×2), washed once with saturated brine, and evaporated under reduced pressure to remove ethyl acetate. The oily target product was obtained by column chromatography with a yield of 83%.

[0080] The NMR data are as follows:

[0081] Such as image 3 shown, 1 H NMR (400MHz, CDCl 3 ):δ=7.87(d, J=8.2Hz, 2H), 7.33(d, J=8.2Hz, 2H), 4.52(s, 2H), 2.46(s, 3H).

[0082] Such as Figure 4 shown, 13 C NMR (101MHz, CDCl 3 ):δ=191.6(s)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com