High-yield and energy-saving production method of peach distilled liquor

A production method and technology for distilled wine, applied in the field of food and beverage processing, can solve problems such as being unsuitable for small and medium-scale distilled wine production, low utilization rate of peach pulp filtration raw materials, affecting the quality of peach fermented wine, etc. Improve the effect of clarification and separation, and avoid the effect of clarification and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

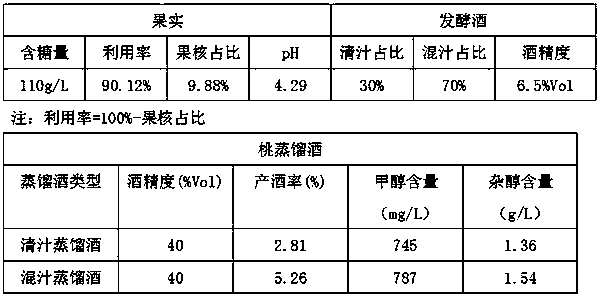

Embodiment 1

[0045] In June 2017, Mengyin peaches were used to brew peach distilled wine. The steps are as follows:

[0046] Material selection: choose moderately overripe fruits, pick out rotten and diseased fruits and leaves and other sundries, and remove the core and crush the fruits as soon as possible after the selection is over, so as to avoid fruit rupture caused by long-term extrusion of fruits, thus infecting miscellaneous plants. bacteria.

[0047] Beating: Wash and remove the core of the screened fruit, and use a mixer with a rotating blade to beat the fruit into a homogenate by secondary crushing. The particle size in the homogenate is less than 0.5cm. Put the homogenate into the fermenter that has been filled with carbon dioxide in advance. And calculate the proportion and utilization rate of the fruit stone, and measure the sugar content and pH of the peach pulp.

[0048] Sulfur adjustment: adjust sulfur to 80mg / L to prevent oxidation of peach homogenate and inhibit the act...

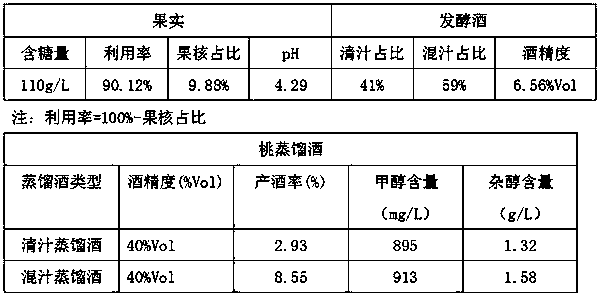

Embodiment 2

[0060] In June 2017, Mengyin peaches were used to brew peach distilled wine. The steps are as follows:

[0061] Material selection: Choose moderately overripe fruits, pick out rotten and diseased fruits and leaves and other sundries, and remove the core and crush the fruits as soon as possible after the selection is over, so as to avoid fruit rupture caused by long-term extrusion between fruits, which will cause infection Miscellaneous bacteria.

[0062] Beating: Wash and remove the core of the screened fruit, and use a mixer with a rotating blade to beat the fruit into a homogenate by secondary crushing. The particle size in the homogenate is less than 0.5cm. Put the homogenate into the fermenter that has been filled with nitrogen in advance. And calculate the proportion and utilization rate of the fruit stone, and measure the sugar content and pH of the peach pulp.

[0063] Sulfur adjustment: adjust sulfur to 70mg / L to prevent oxidation of peach homogenate and inhibit the ...

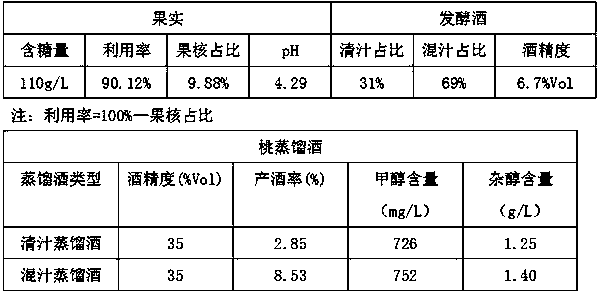

Embodiment 3

[0075] Prepare peach distilled wine according to the method of embodiment 1, difference is: used peach is the mature Feicheng peach of Tai'an City, Shandong.

[0076] Present embodiment raw material and product technical parameter are as follows:

[0077]

[0078] Note: Liquor production rate=volume of 40% Vol distilled liquor / volume of fermented liquor; test method for methanol content: gas chromatography; test method for fusel alcohol content: gas chromatography-mass spectrometry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com