A kind of preparation method of sustained-release anthocyanin microcapsules

A technology of microcapsules and anthocyanins, which is applied in the forming of food, the function of food ingredients, and food ingredients containing natural extracts, etc. It can solve the problems of anthocyanins being easily damaged, poor slow-release effect, and low embedding rate, etc. problem, to achieve enhanced bioavailability, accelerated dehydration, and reduced enzymatic browning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

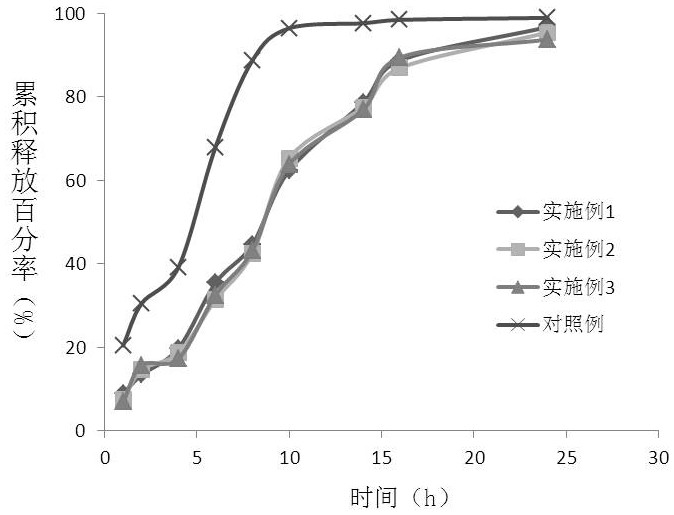

Image

Examples

Embodiment 1

[0028] A preparation method of slow-release anthocyanin microcapsules, the specific operation steps are as follows:

[0029] Step 1: Take peony petals at the flower bud stage, remove impurities and wash them, dry the surface moisture, and set aside; 700MHz microwave for 5 minutes to obtain pretreated materials.

[0030] Step 2, add 60 DEG C of distilled water in the pretreatment material, heat preservation treatment 10min, get the primary material; Add 2% phenylalanine, 3% salt and 1.7% citric acid of its mass in the primary material, stir Dissolving phenylalanine, salt and citric acid, beating to obtain a slurry; hydraulically filtering the slurry at a pressure of 30MP to obtain a filtrate; wherein, the amount of distilled water added is 1 / 3 of the mass of the pretreated material.

[0031] Step 3: Add modified starch, casein and maltodextrin to the filtrate, treat in a water bath at 55-60°C and stir until fully dissolved to obtain a mixed solution; wherein, the amount of modi...

Embodiment 2

[0038] A preparation method of slow-release anthocyanin microcapsules, the specific operation steps are as follows:

[0039] Step 1: Take peony petals at the flower bud stage, remove impurities and wash them, dry the surface moisture, and set aside; 710MHz microwave for 6 minutes to obtain pretreated materials.

[0040] Step 2, add 65 DEG C of distilled water in the pretreatment material, heat preservation treatment 8min, get the primary material; Add its mass fraction in the primary material to be 3% phenylalanine, 3.5% salt and 1.8% citric acid, Stir to dissolve and make an oar to obtain a slurry; hydraulically filter the slurry at a pressure of 35MP to obtain a filtrate; wherein the amount of distilled water added is 1 / 3 of the mass of the pretreated material.

[0041] Step 3: Add modified starch, casein and maltodextrin to the filtrate, treat in a water bath at 55-60°C and stir until fully dissolved to obtain a mixed solution; wherein, the amount of modified starch, casein...

Embodiment 3

[0048] A preparation method of slow-release anthocyanin microcapsules, the specific operation steps are as follows:

[0049] Step 1. Take peony petals at the flower bud stage, remove impurities and wash them, dry the surface moisture, and set aside; microwave at 720 MHz for 5 minutes to obtain pretreated materials.

[0050] Step 2, add 63 DEG C of distilled water in the pretreatment material, heat preservation treatment 10min, get the primary material; Add its mass fraction in the primary material to be 2.5% phenylalanine, 3.2% salt and 1.5% citric acid, Stir to dissolve, beating to obtain a slurry; hydraulically filter the slurry at a pressure of 40MP to obtain a filtrate; wherein, the amount of distilled water added is 1 / 2 of the mass of the pretreated material.

[0051] Step 3: Add modified starch, casein and maltodextrin to the filtrate, treat in a water bath at 55-60°C and stir until fully dissolved to obtain a mixed solution; wherein, the amount of modified starch, casei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com