A kind of preparation SIO from low-grade kaolin 2 / al 2 o 3 Composite Methods

A composite material, kaolin technology, applied in chemical instruments and methods, water/sludge/sewage treatment, silicon compounds, etc., to avoid waste of resources, promote the construction of ecological civilization, and achieve good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

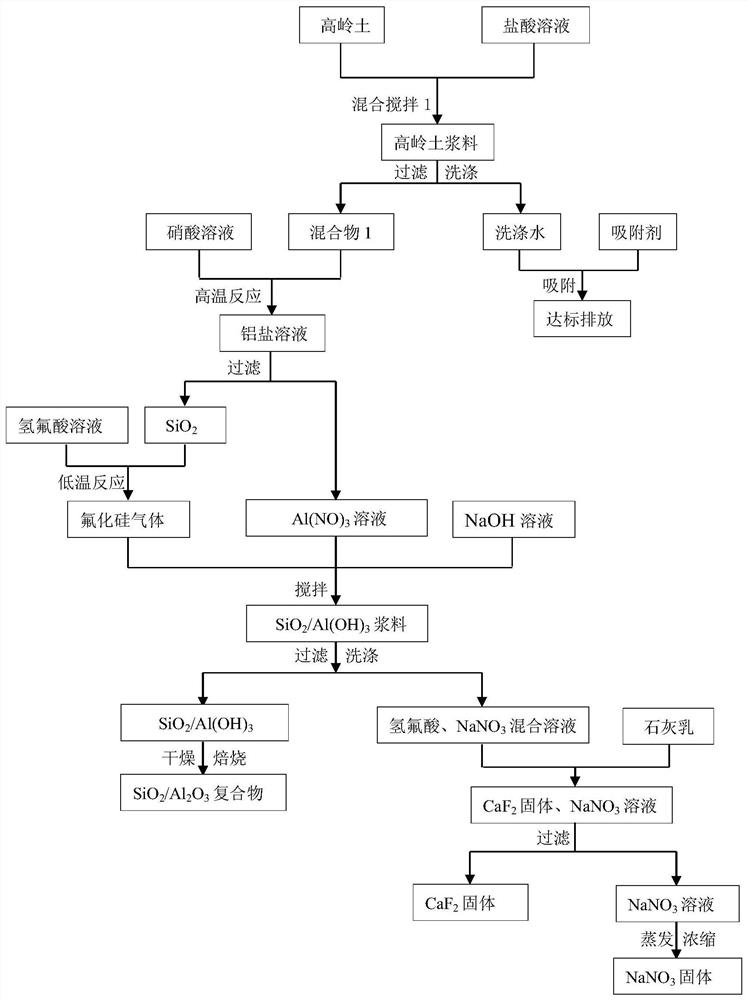

[0031] Weigh 100g of kaolin and add it into a stirred tank filled with 300ml of 5% dilute hydrochloric acid solution by mass fraction, stir for 30min, pour the mixed solution in the stirred tank into the filter residue obtained by filtering in a separator and about 400ml of washing water. Pass the above-mentioned washing water into the sedimentation tank, add 4g of adsorbent and keep stirring for 60 minutes, then stop stirring, and discharge the solution after reaching the standard. The filter residue is then reacted with 200ml mass fraction of 30% nitric acid solution in a reaction kettle at 150° C. After reacting for 2 hours, filter to obtain aluminum salt solution and solid SiO 2 , mix the solid with 200ml of hydrofluoric acid and collect the silicon fluoride gas with a gas collection bag; mix and stir the aluminum salt solution with 40g of sodium hydroxide in the reactor for 20 minutes, and then pass the silicon fluoride gas collected above into the reactor middle. After ...

Embodiment 2

[0033] Weigh 100g of kaolin and add it into a stirred tank filled with 200ml of 10% dilute hydrochloric acid solution by mass fraction, stir for 30min, pour the mixed solution in the stirred tank into the filter residue obtained by filtering in a separator and about 400ml of washing water. Pass the above-mentioned washing water into the sedimentation tank, add 4g of adsorbent and keep stirring for 60 minutes, then stop stirring, and discharge the solution after reaching the standard. The filter residue is then reacted with 150ml mass fraction of 40% nitric acid solution in a reaction kettle at 150° C. After reacting for 2 hours, filter to obtain aluminum salt solution and solid SiO 2 , mix the solid with 200ml of hydrofluoric acid and collect the silicon fluoride gas with a gas collection bag; mix and stir the aluminum salt solution with 40g of sodium hydroxide in the reactor for 20 minutes, and then pass the silicon fluoride gas collected above into the reactor middle. After...

Embodiment 3

[0035] Weigh 100g of kaolin and add it into a stirred tank filled with 200ml of dilute hydrochloric acid solution with a mass fraction of 20%, stir for 30min, pour the mixed solution in the stirred tank into the filter residue obtained by filtering in a separator and about 400ml of washing water. Pass the above-mentioned washing water into the sedimentation tank, add 4g of adsorbent and keep stirring for 60 minutes, then stop stirring, and discharge the solution after reaching the standard. The filter residue is then reacted with 150ml mass fraction of 40% nitric acid solution in a reaction kettle at 150° C. After reacting for 2 hours, filter to obtain aluminum salt solution and solid SiO 2 , mix the solid with 200ml of hydrofluoric acid and collect the silicon fluoride gas with a gas collection bag; mix and stir the aluminum salt solution with 40g of sodium hydroxide in the reactor for 20 minutes, and then pass the silicon fluoride gas collected above into the reactor middle....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com