Hemihydrate gypsum aerated concrete board and preparation method thereof

A technology of aerated concrete slabs and hemihydrate gypsum, applied in the field of concrete, can solve the problems of gypsum products such as water resistance, strength decline, and variability, and achieve the effects of lowering procurement standards, improving strength, and enhancing frost resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The raw material components are: 50kg of hemihydrate gypsum, 120kg of lime, 100kg of cement, 650kg of sand, 80kg of waste slurry, and 0.7kg of aluminum powder paste;

[0028] Preparation method: (1) Mix sand and waste slurry and pour them into a ball mill, add water and mix them evenly, and grind until the sieve residue through a 0.08mm square hole sieve is 22%, the water content is 40%, the specific gravity is 1.6, and the diffusivity is 38cm slurry;

[0029] (2) mixing aluminum paste powder with water to obtain aluminum powder paste;

[0030] (3) Add the slurry, cement, lime, and hemihydrate gypsum into the pouring mixing tank. After the addition, control the diffusion degree to 27 cm. After stirring for 2.5 minutes, add the aluminum powder paste in step (2), and stir for 40 seconds;

[0031] (4) pouring the mortar obtained in step (3), the pouring temperature is 43°C;

[0032] (5) After the pouring is completed, send it to the inserting position, insert the prepare...

Embodiment 2

[0036] The raw material components are: 6kg of hemihydrate gypsum, 11kg of lime, 11kg of cement, 44kg of sand, 20kg of fly ash, 8kg of waste slurry, and 0.07kg of aluminum powder paste; the preparation method is the same as in Example 1;

Embodiment 3

[0038] The raw material components are: 60kg of hemihydrate gypsum, 100kg of lime, 100kg of cement, 300kg of sand, 200kg of fly ash, 160kg of phosphorus slag, 80kg of waste in waste slurry, and 0.7kg of aluminum powder paste; the preparation method is the same as in Example 1;

[0039] In the embodiment of the present invention: the sand is silica sand with a mud content of ≤15% and a silicon dioxide content of ≥75%.

[0040] The lime is quicklime, and its effective calcium oxide content is more than or equal to 70%.

[0041] The cement is P.042.5 ordinary Portland cement.

[0042] The hemihydrate gypsum is prepared by heating raw gypsum to 150-170° C. to lose water.

[0043] The raw materials also include fly ash or phosphorus slag; the fly ash is solid waste after coal combustion in a thermal power plant; Silicon oxide 40-43%;

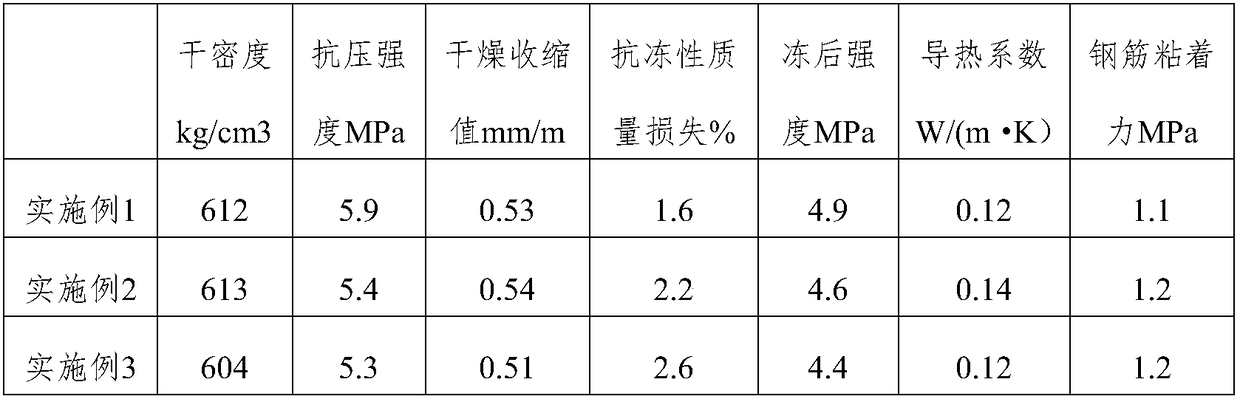

[0044] The finished products prepared by the schemes of Examples 1 to 3 were tested respectively, and the dry density, compressive strength, dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com