High-intensity and super-sulphur ardealite slag cement concrete and preparation method thereof

A slag cement and concrete technology, applied in the field of building materials, can solve the problems of concrete strength reduction, early strength reduction, delaying ettringite, etc., and achieve the effect of shortening the setting time, improving early strength, and easy mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

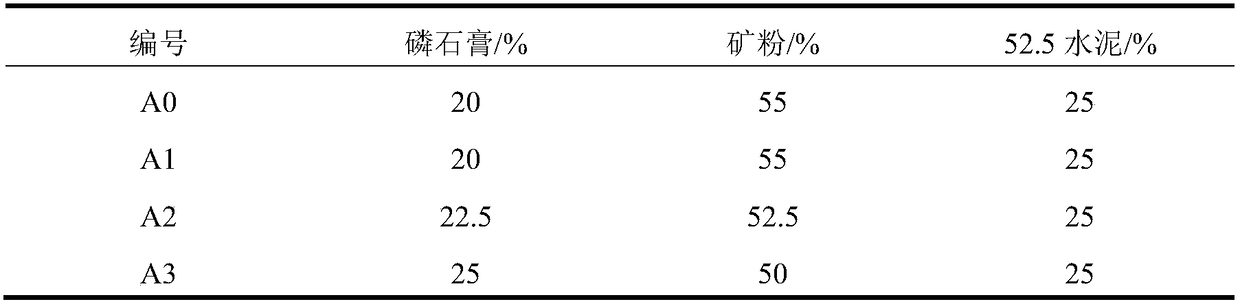

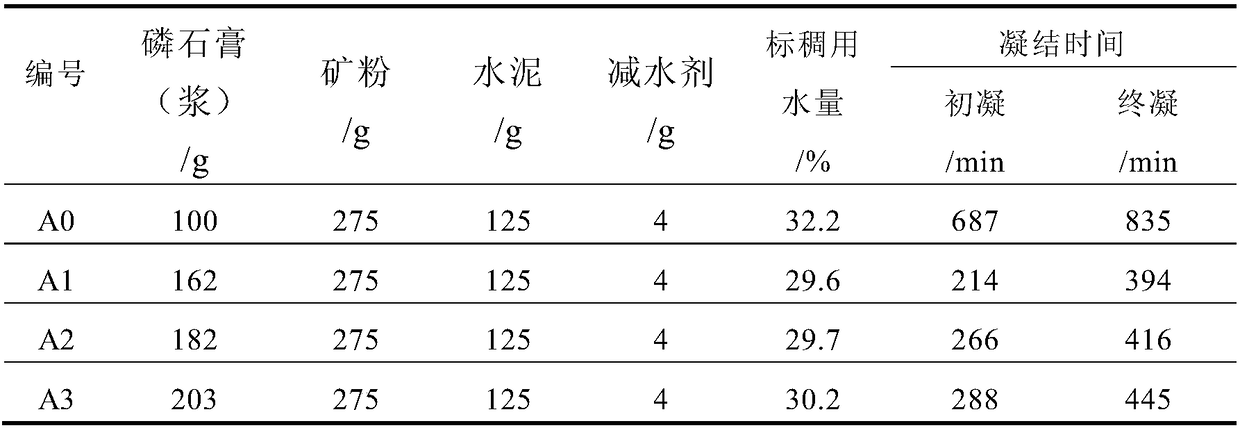

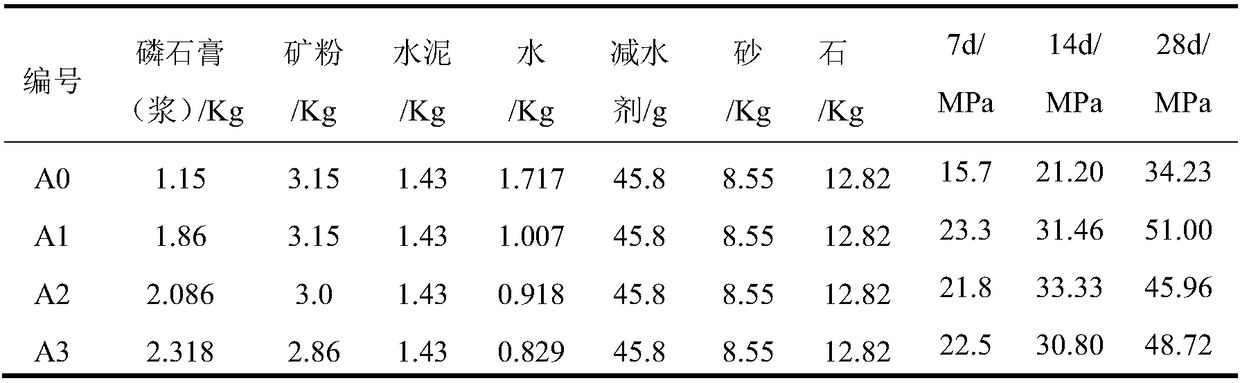

Method used

Image

Examples

Embodiment 1

[0038] To prepare a high-strength ultra-sulfur phosphogypsum slag cement concrete, the raw materials used are: phosphogypsum (average particle size 0.5mm) dried in an oven at 40°C until the moisture content is less than 0.1%, S95 grade slag powder, first-grade pulverized coal Ash (average particle size about 20 μm), P.O.42.5 cement produced by Huaxin Cement Factory, polycarboxylate water reducer (solid content 20%), sand with a particle size of less than 5 mm, stones with a particle size of 5 to 25 mm, and water. Concrete preparation method steps are as follows:

[0039] 1) Phosphogypsum ball milling pretreatment: put 3000g of phosphogypsum, 20g of fly ash, 40g of cement, 18.36g of water reducer and 1683g of water in a ball mill tank for wet grinding for 20min, then sieve out and perform aging treatment for 8h to obtain phosphorus gypsum slurry;

[0040] 2) Preparation of supersulfophosphogypsum slag cement concrete: Add 8.55Kg sand, 12.8Kg stone and 0.43Kg water into the con...

Embodiment 2

[0042] To prepare a high-strength ultra-sulfur phosphogypsum slag cement concrete, the raw materials used are: phosphogypsum (average particle size 0.5mm) dried in an oven at 40°C until the moisture content is less than 0.1%, S95 grade slag powder, first-grade pulverized coal Ash (average particle size about 20 μm), P.O.42.5 cement produced by Huaxin Cement Factory, polycarboxylate water reducer (solid content 20%), sand with a particle size of less than 5 mm, stones with a particle size of 5 to 25 mm, and water. Concrete preparation method steps are as follows:

[0043] 1) Phosphogypsum ball milling pretreatment: put 3000g of phosphogypsum, 20g of fly ash, 40g of cement, 18.36g of water reducer and 1683g of water in a ball mill tank for wet grinding for 20min, then sieve out and perform aging treatment for 8h to obtain phosphorus gypsum slurry;

[0044] 2) Preparation of supersulfophosphogypsum slag cement concrete: Add 8.55Kg sand, 12.8Kg stone and 0.43Kg water into the con...

Embodiment 3

[0046] To prepare a high-strength ultra-sulfur phosphogypsum slag cement concrete, the raw materials used are: phosphogypsum (average particle size 0.5mm) dried in an oven at 40°C until the moisture content is less than 0.1%, S95 grade slag powder, first-grade pulverized coal Ash (average particle size about 20 μm), P.O.42.5 cement produced by Huaxin Cement Factory, polycarboxylate water reducer (solid content 20%), sand with a particle size of less than 5 mm, stones with a particle size of 5 to 25 mm, and water. Concrete preparation method steps are as follows:

[0047] 1) Phosphogypsum ball milling pretreatment: put 3000g of phosphogypsum, 20g of fly ash, 40g of cement, 18.36g of water reducer and 1683g of water in a ball mill tank for wet grinding for 20min, then sieve out and perform aging treatment for 8h to obtain phosphorus gypsum slurry;

[0048] 2) Preparation of supersulfophosphogypsum slag cement concrete: Add 8.55Kg sand, 12.8Kg stone and 0.43Kg water into the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com