Preparation method of neopentyl glycol dimethacrylate

A technology of neopentyl glycol dimethacrylate and methacrylic acid, which is applied to the preparation of carboxylic acid esters, the preparation of organic compounds, chemical instruments and methods, etc., and can solve the problem of large amounts of by-products and waste water and serious environmental impacts , low yield and low chroma, and achieve the effects of high yield, simple operation and low chroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

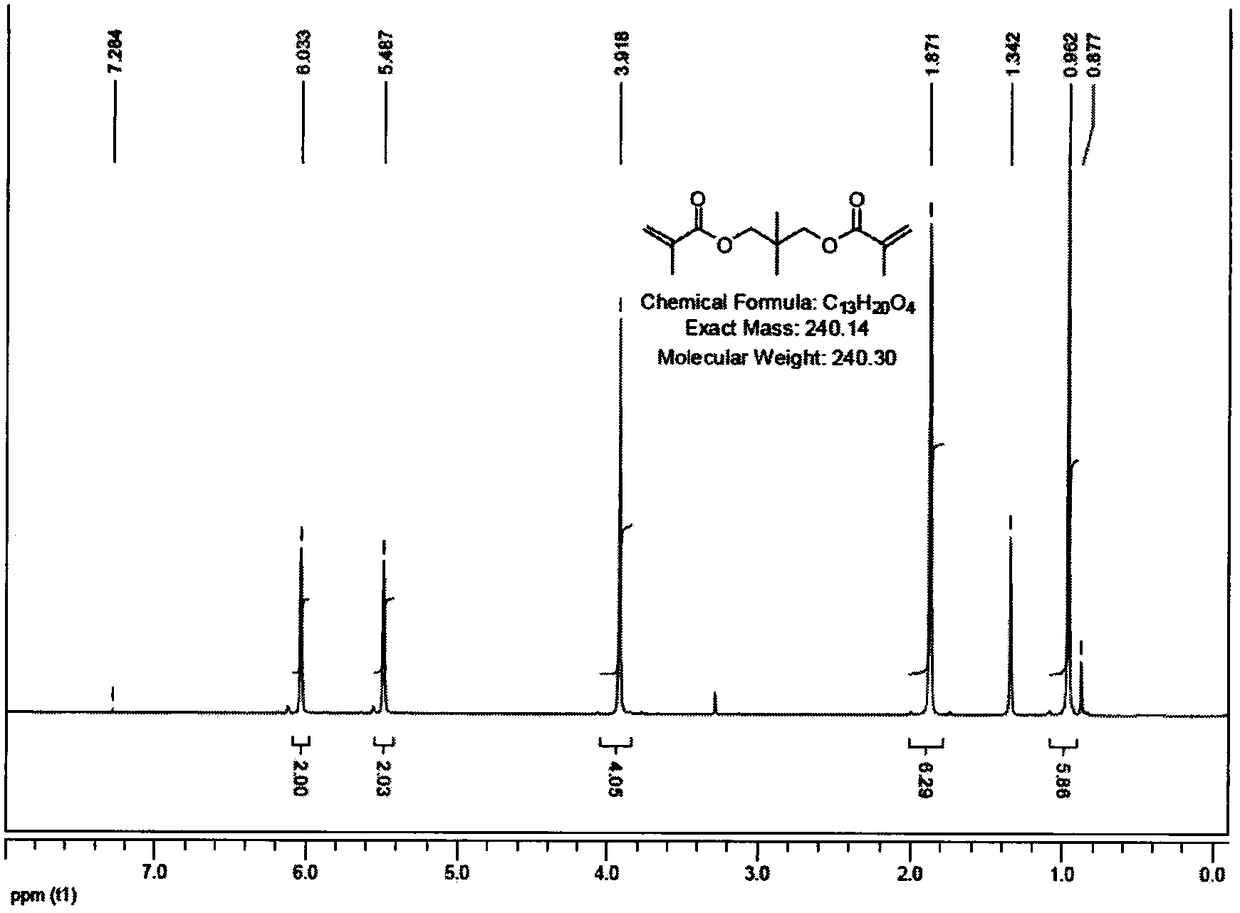

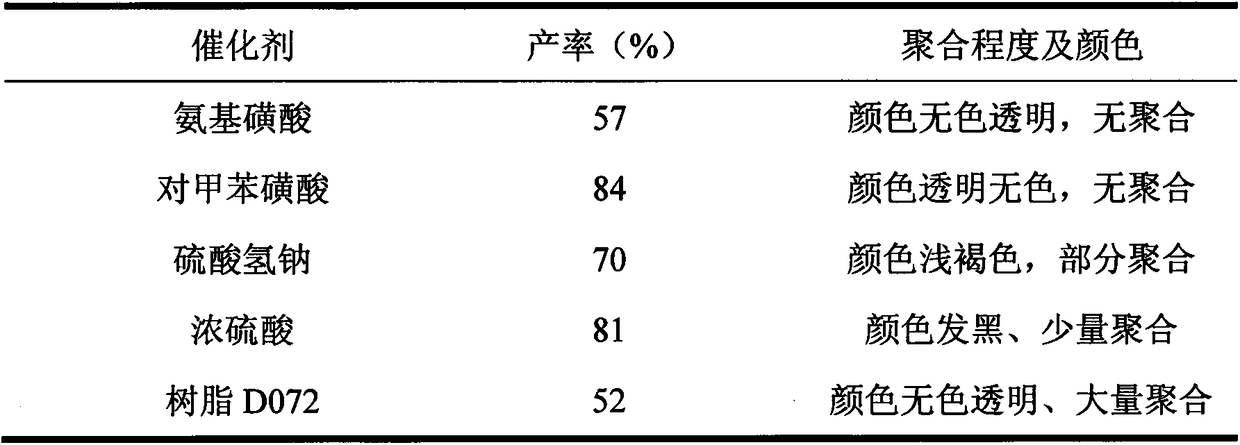

[0018] This embodiment provides a kind of preparation method of neopentyl glycol dimethacrylate. Take by weighing 92.54g methacrylic acid, 52.07g neopentyl glycol (the mol ratio of methacrylic acid and neopentyl glycol is 2.15: 1.0), 5.78g p-toluenesulfonic acid catalyst (4% of reactant gross weight) respectively, 0.144g phenothiazine polymerization inhibitor (0.1% of reactant gross weight) and 65.07g hexanaphthene (45% of reactant gross weight) join in the 500mL there-necked flask, adorn thermometer, reflux condenser and oil-water separator , turn on magnetic stirring and heating, control the reaction temperature at 84-86° C., and react for 5 hours to obtain neopentyl glycol dimethacrylate. Cool to room temperature, filter, decolorize with activated carbon, add saturated sodium bicarbonate solvent to the mixed solution to wash, then wash with distilled water for 1-2 times, let stand to separate layers, take the upper organic phase, and distill off the organic solvent under re...

Embodiment 2

[0020] This embodiment provides a kind of preparation method of neopentyl glycol dimethacrylate. Take by weighing 88.24g methacrylic acid, 52.07g neopentyl glycol (the mol ratio of methacrylic acid and neopentyl glycol is 2.05: 1.0), 4.21g p-toluenesulfonic acid catalyst (3% of reactant gross weight) respectively, 0.070g phenothiazine polymerization inhibitor (0.05% of reactant gross weight) and 70.16g hexanaphthene (50% of reactant gross weight) join in the 500mL there-necked flask, adorn thermometer, reflux condenser and oil-water separator , start magnetic stirring and heating, control the reaction temperature at 84-86° C., and react for 4 hours to obtain neopentyl glycol dimethacrylate. Cool to room temperature, filter, decolorize with activated carbon, add saturated sodium bicarbonate solvent to the mixed solution to wash, then wash with distilled water for 1-2 times, let stand to separate layers, take the upper organic phase, and distill off the organic solvent under red...

Embodiment 3

[0022] This embodiment provides a kind of preparation method of neopentyl glycol dimethacrylate. Take by weighing 94.64g methacrylic acid, 52.07g neopentyl glycol (the mol ratio of methacrylic acid and neopentyl glycol is 2.20: 1.0), 5.86g p-toluenesulfonic acid catalyst (3% of reactant gross weight) respectively, 0.073g phenothiazine polymerization inhibitor (0.05% of reactant gross weight) and 58.68g hexanaphthene (50% of reactant gross weight) join in the 500mL there-necked flask, adorn thermometer, reflux condenser and oil-water separator , turn on magnetic stirring and heating, control the reaction temperature at 78-80° C., and react for 7 hours to obtain neopentyl glycol dimethacrylate. Cool to room temperature, filter, decolorize with activated carbon, add saturated sodium bicarbonate solvent to the mixed solution to wash, then wash with distilled water for 1-2 times, let stand to separate layers, take the upper organic phase, and distill off the organic solvent under r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com