High-strength nano composite hydrogel and preparation method thereof

A nanocomposite, hydrogel technology, applied in the field of polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

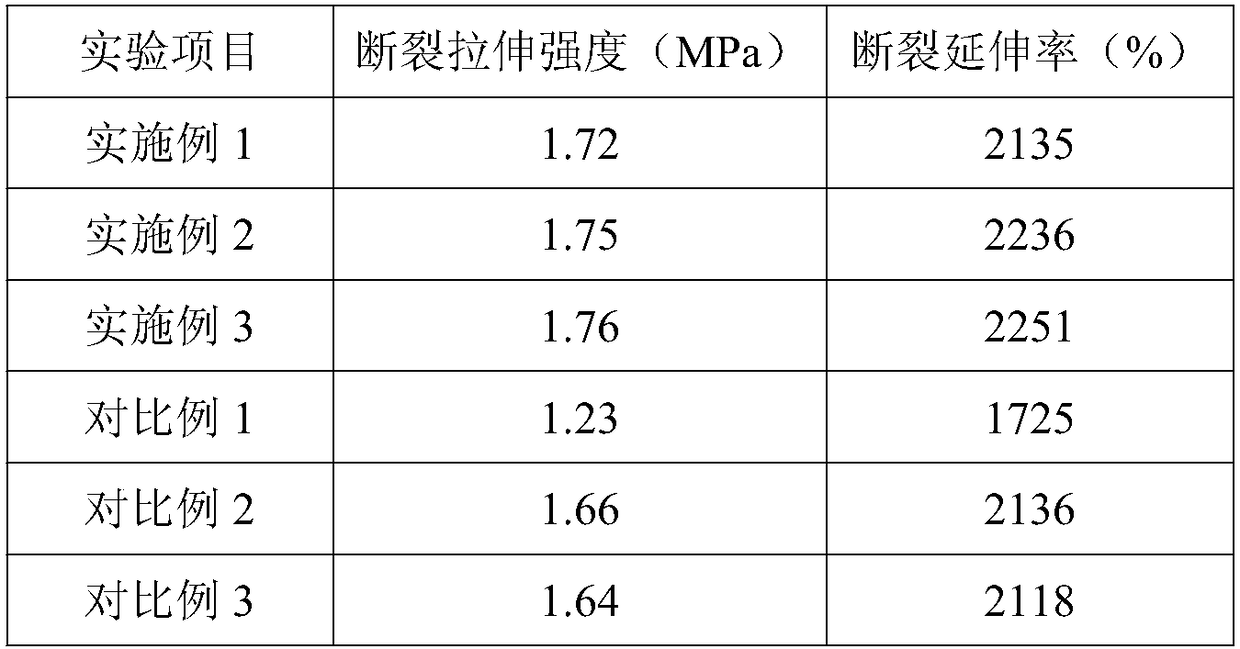

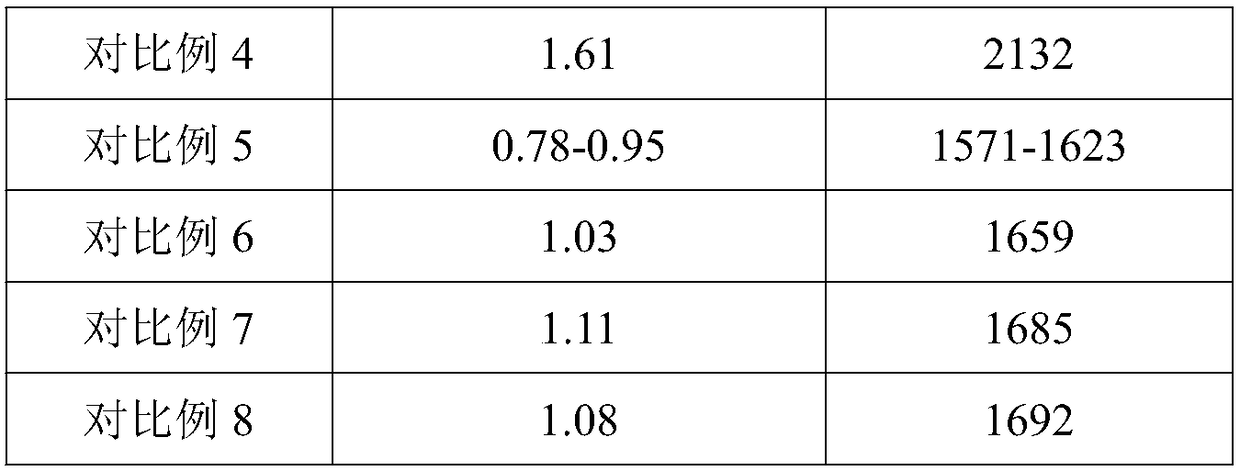

Examples

preparation example Construction

[0029] The preparation method of described high-strength nanocomposite hydrogel comprises the following steps:

[0030] S1: add graphite oxide into deionized water and ultrasonically peel for 20-30 minutes to obtain a graphene oxide aqueous solution, then add styrene, and process graphene oxide and styrene by ball milling to prepare a styrene / graphene oxide nanocomposite material;

[0031] S2: Take 10-20 parts of shredded eucalyptus wood pulp, add 90-110ml of sodium hydroxide with a concentration of 4wt%, and fully react at 70-90°C for 2 hours to obtain a cellulose pre-reactant; add 65wt to the cellulose pre-reactant % concentrated sulfuric acid solution, mixed evenly, placed in a water bath at 50-60°C for 2 hours, then centrifuged and precipitated to obtain a cellulose suspension, and then the cellulose suspension was centrifuged to remove larger-sized precipitates, crystallized, and prepared Obtain nanocellulose crystals; the particle size of the nanocellulose crystals is 22...

Embodiment 1

[0036] A high-strength nanocomposite hydrogel, in parts by weight, comprising the following components: 45 parts of polyvinyl alcohol, 55 parts of carboxymethyl chitosan, 14 parts of modified graphene oxide, 10 parts of sodium alginate, 8 parts of oxidized hydroxypropyl starch, 3 parts of citric acid, 1.5 parts of tetramethylethylenediamine, 10 parts of nanocellulose crystals, 3 parts of hydrogen peroxide, and 5 parts of sodium benzenesulfonate.

[0037] The preparation method of described high-strength nanocomposite hydrogel comprises the following steps:

[0038] S1: adding graphite oxide into deionized water and ultrasonically stripping for 30 minutes to obtain a graphene oxide aqueous solution, then adding styrene, and treating graphene oxide and styrene with a ball milling method to prepare a styrene / graphene oxide nanocomposite material;

[0039] S2: Take 15 parts of crushed eucalyptus pulp, add 90ml of sodium hydroxide with a concentration of 4wt%, and fully react at 90...

Embodiment 2

[0044] A high-strength nanocomposite hydrogel, in parts by weight, comprising the following components: 65 parts of polyvinyl alcohol, 45 parts of carboxymethyl chitosan, 12 parts of modified graphene oxide, 8 parts of sodium alginate, 5 parts of oxidized hydroxypropyl starch, 2 parts of citric acid, 0.5 parts of tetramethylethylenediamine, 20 parts of nanocellulose crystals, 7 parts of hydrogen peroxide, and 8 parts of sodium benzenesulfonate.

[0045] The preparation method of described high-strength nanocomposite hydrogel comprises the following steps:

[0046] S1: Add graphite oxide into deionized water and ultrasonically peel for 25 minutes to obtain a graphene oxide aqueous solution, then add styrene, and process graphene oxide and styrene by ball milling to prepare a styrene / graphene oxide nanocomposite material;

[0047] S2: Take 10 parts of crushed eucalyptus wood pulp and add 110ml of sodium hydroxide with a concentration of 4wt%, and fully react at 80°C for 2 hours ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com