Mud cake hardening enhancer for drilling fluid

A technology of reinforcing agent and drilling fluid, which is applied in the field of drilling fluid additives to achieve stable product performance, improved cementing quality, and improved cementing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 32g of bishydroxyethoxypropyl polydimethylsiloxane, 48g of silicon whisker, fiber length of silicon whisker of 300μm, diameter of 5μm, 3-aminopropylmethyldiethoxysilane The weight is 6g, the layered crystalline sodium disilicate is 10g, the acrylic acid-hydroxypropyl acrylate copolymer T-225 is 4g, and they are mixed uniformly to prepare a mud cake hardening enhancer product for drilling fluid.

Embodiment 2

[0033] Weigh 35g of bishydroxyethoxypropyl polydimethylsiloxane, 42g of silicon whisker, fiber length of silicon whisker of 150μm, diameter of 10μm, 3-aminopropylmethyldiethoxysilane The weight is 8g, the layered crystalline sodium disilicate is 12g, the acrylic acid-hydroxypropyl acrylate copolymer T-225 is 3g, and they are mixed uniformly to prepare a mud cake hardening enhancer product for drilling fluid.

Embodiment 3

[0035] Weigh 38g of bishydroxyethoxypropyl polydimethylsiloxane, 36g of silicon whisker, fiber length of silicon whisker of 500μm, diameter of 10μm, 3-aminopropylmethyldiethoxysilane The weight is 10g, the layered crystalline sodium disilicate is 14g, the acrylic acid-hydroxypropyl acrylate copolymer T-225 is 2g, and they are mixed uniformly to prepare a mud cake hardening enhancer product for drilling fluid.

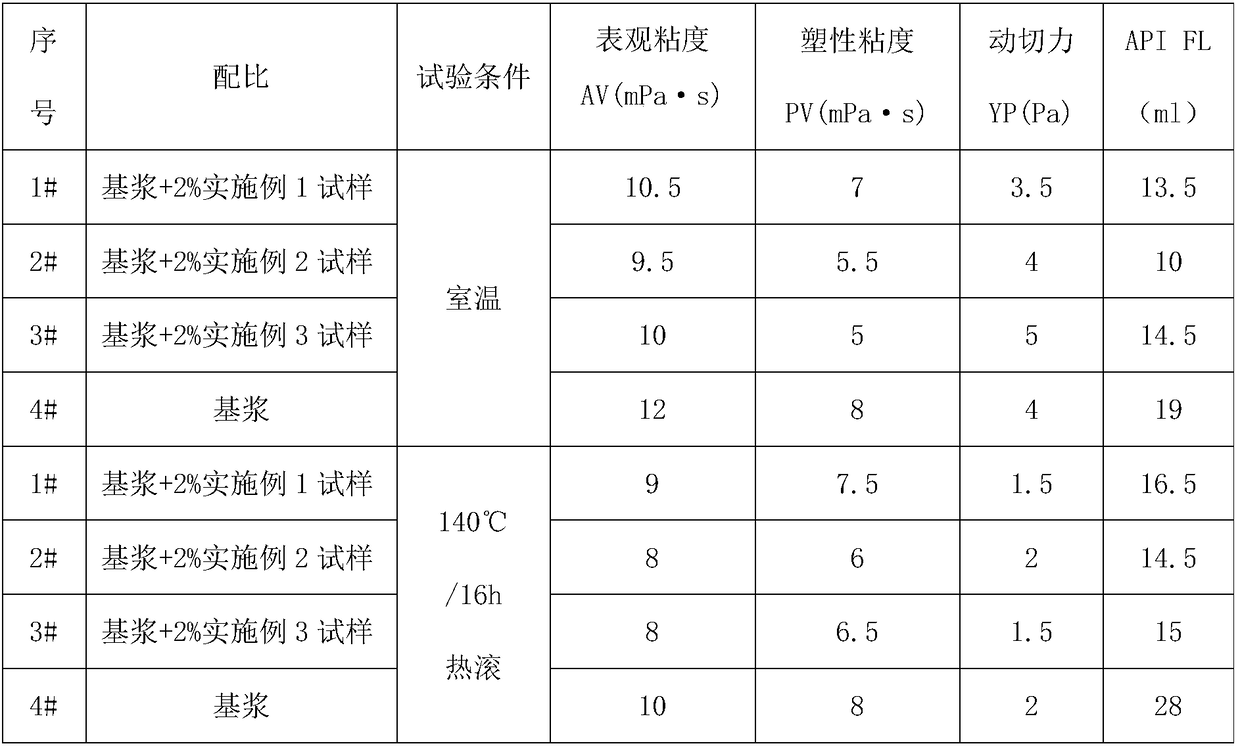

[0036] The performance evaluation of the mud cake hardening enhancer for drilling fluids of the above examples was performed by the following methods.

[0037] (1) The evaluation methods of compatibility with drilling fluid and high temperature resistance are as follows:

[0038] The drilling fluid used is a 4% base slurry, which is to add 4 g of sodium bentonite per 100 mL of water to fully stir it evenly, seal it and let it stand, and cure it at room temperature for 24 hours to obtain a base slurry.

[0039] (1.1) Room temperature performance evaluation: prepare 4 slurry cups...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com