Flame-retarded resin finishing agent for water-based coating and preparation method of flame-retarded resin finishing agent

A technology of flame-retardant resin and water-based coating, applied in the direction of flame-retardant fiber, fiber treatment, fiber type, etc., can solve the problems of high process stability requirements, lengthy process, and insufficient effect stability in production plants, etc., and achieve reduction Emission of VOC, reduction of multiple processes, and improvement of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

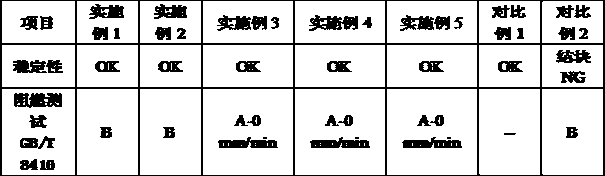

Examples

Embodiment 1

[0021] A flame-retardant resin finishing agent for water-based coatings. The parts by weight of the raw materials are: 40 parts of polyester polyurethane, 5 parts of modified ammonium polyphosphate, 10 parts of cyclic phosphate, alkali-swellable 2 parts of thickening agent, 1 part of nano-sized titanium dioxide rutile type, 1.5 parts of cellulose ether, 4 parts of blocked isocyanate bridging agent and 36.5 parts of water.

[0022] According to the proportion, add water and cellulose ether into the reaction kettle, put in nano-sized titanium dioxide rutile, stir at high speed, stir evenly, put in modified ammonium polyphosphate and cyclic phosphate and continue stirring, then put in polyester polyurethane, stir evenly Finally, adjust the pH value of the system to 6-8, add an alkali-swellable thickener to adjust the viscosity, and finally put in a blocked isocyanate bridging agent and stir evenly.

[0023] A method for using a flame-retardant resin finishing agent for water-base...

Embodiment 2

[0025] A flame-retardant resin finishing agent for water-based coatings. The parts by weight of the raw materials are: 50 parts of polyether polyurethane, 5 parts of modified ammonium polyphosphate, 5 parts of cyclic phosphate, alkali-swellable 2 parts of thickening agent, 1 part of nano-sized titanium dioxide rutile type, 1.5 parts of lignin sulfonate, 4 parts of blocked aziridine bridging agent and 30 parts of water.

[0026] According to the proportion, add water and lignin sulfonate into the reaction kettle, put in nano-sized titanium dioxide rutile, stir at high speed, stir evenly, put in modified ammonium polyphosphate and cyclic phosphate and keep stirring, then put in polyether polyurethane, stir After uniformity, adjust the pH value of the system, add an alkali swelling thickener to adjust the viscosity, and finally put in a closed aziridine bridging agent and stir evenly.

[0027] A method for using a flame-retardant resin finishing agent for water-based coatings. Af...

Embodiment 3

[0029] A flame-retardant resin finishing agent for water-based coatings, the parts by weight of each raw material are: 15 parts of polyester polyurethane, 15 parts of polyether polyurethane, 10 parts of cyclic phosphate, and 10 parts of pentaerythritol phosphate emulsion , 2 parts of polyurethane associative thickener, 1 part of nano titanium dioxide rutile type, 1.5 parts of cellulose ether, 3 parts of blocked isocyanate bridging agent and 50 parts of water.

[0030] According to the proportion, add water and cellulose ether into the reaction kettle, put in nano-sized titanium dioxide rutile type, stir at high speed, stir evenly, put in cyclic phosphate and pentaerythritol phosphate emulsion and keep stirring, then put in polyester polyurethane and polyether For polyurethane, adjust the pH value of the system after stirring evenly, add polyurethane associative thickener to adjust the viscosity, and finally put in blocked isocyanate bridging agent and stir evenly.

[0031] A m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com