Ethylene-octene copolymer tarpaulin and processing technology thereof

An octene copolymer and ethylene technology is applied in the field of ethylene-octene copolymer tarpaulin and its processing technology. Good, good chemical stability, good chemical stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose of the invention, technical solutions and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods;

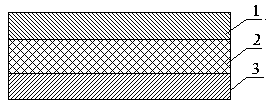

[0031] In the accompanying drawings: An ethylene-octene copolymer tarpaulin is characterized in that: it comprises a polypropylene woven fabric 2, a smooth POE coating layer 1 is arranged on the polypropylene woven fabric 2, and a polypropylene woven fabric 2 There is a matte POE coating layer 3 below; the thickness of the smooth POE coating layer 1 is 0.13~0.15mm, and the weight is 115~136g / m 2 ; The thickness of the matte POE coating layer 2 is 0.10~0.13mm; the weight is 90~115g / m 2 ; The weight of 2 grams of polypropylene woven fabric is 170g / m2 .

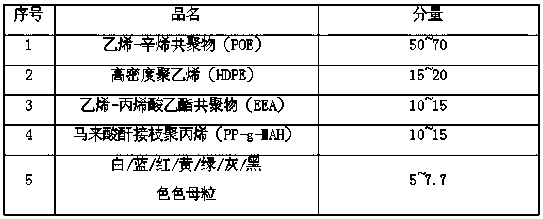

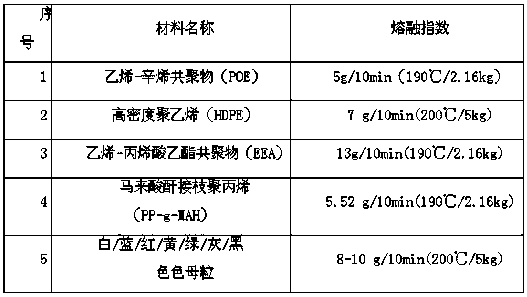

[0032] The composition ratio of the smooth POE coating layer 1 and the matte POE coating layer 3 is the same, and the composition ratio is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com