Light low-friction-coefficient high-abrasion-resistance sliding bearing and preparation method thereof

A low friction coefficient, sliding bearing technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve the problems of poor creep resistance and thermal conductivity, low friction coefficient, poor wear resistance, etc., to achieve matrix stability, The effect of excellent performance and good lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

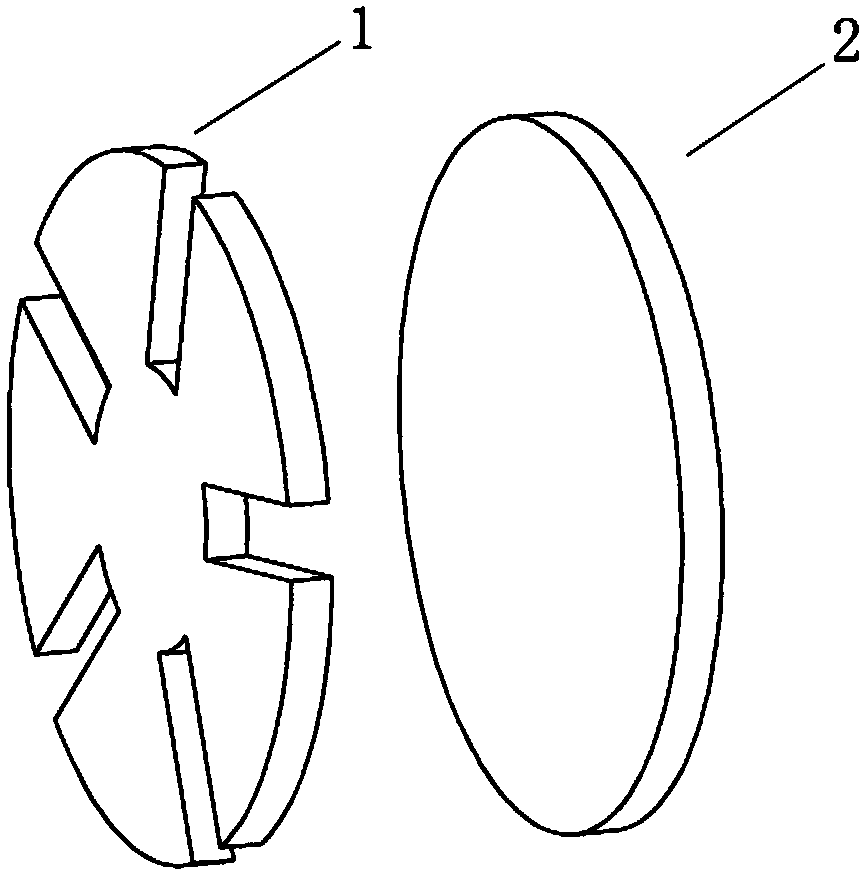

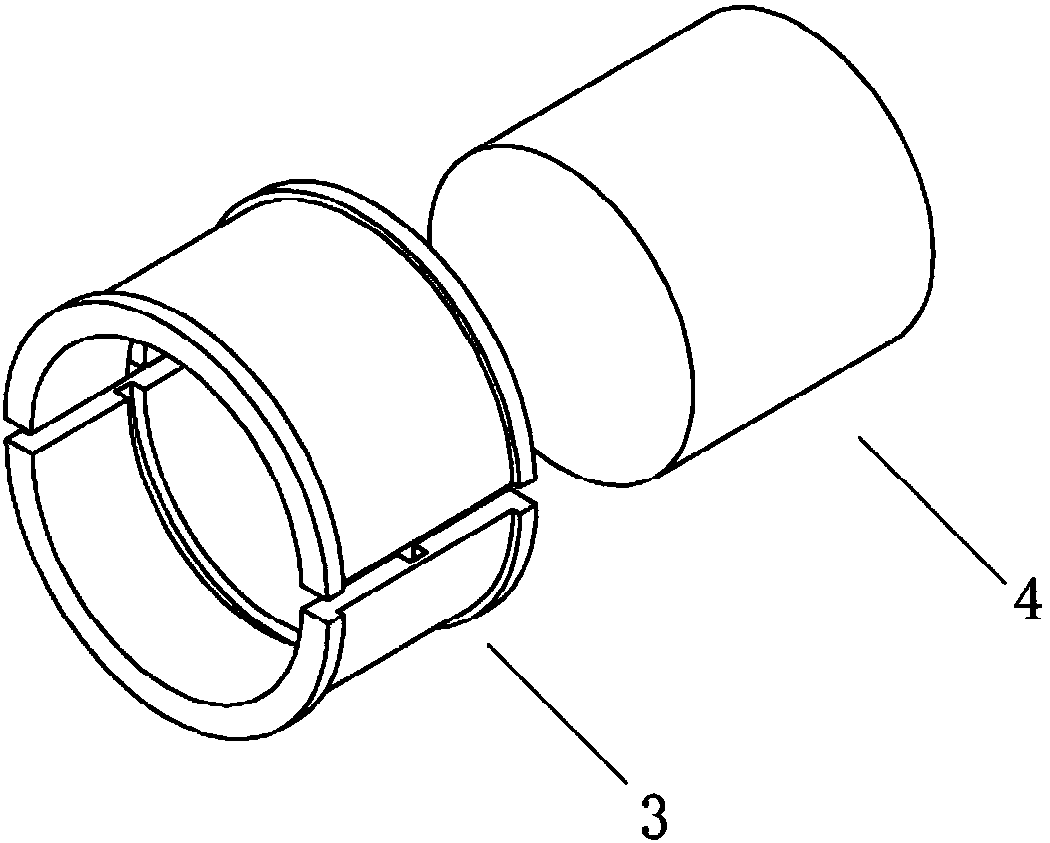

Image

Examples

Embodiment 1

[0033] To prepare a light-weight, low-friction coefficient and high wear-resistant sliding bearing, the steps are as follows:

[0034] Step 1. Weigh micron-sized hard ceramic particle silicon carbide, short carbon fiber and PTFE material, wherein the proportion of filler is 5wt% by weight of silicon carbide, 15wt% by weight of short carbon fiber, and the balance is polytetrafluoroethylene vinyl. The particle size range of micron-sized hard ceramic particles silicon carbide is 0.1-0.4 microns, the short carbon fiber is passed through a 400-mesh sieve, and the polytetrafluoroethylene is PTFE powder with an average particle size of 10-30 microns. When stirring and mixing, weigh 7.5 g of silicon carbide, 22.5 g of short carbon fiber, and 120 g of PTFE.

[0035] Step 2: Mix the micron-sized hard ceramic particles, short carbon fibers and PTFE powder weighed in Step 1, and perform mechanical stirring.

[0036] Step 3. Evenly spread the mixture stirred in Step 2 into a mold, and pe...

Embodiment 2

[0040] Example 2: Preparation of a light-weight, low-friction, high-wear-resistant sliding bearing. The preparation steps are basically the same as in Example 1. The only difference is that the composition ratio of raw materials in step 1 is different, that is, the micron-sized hard ceramic particles of silicon carbide The weight percentage is 10 wt%, the weight percentage of the short carbon fiber is 10 wt%, and the balance is polytetrafluoroethylene. When stirring and mixing, weigh 15 g of silicon carbide, 15 g of short carbon fiber, and 120 g of PTFE.

Embodiment 3

[0041] Example 3: Preparation of a light-weight, low-friction, high-wear-resistant sliding bearing, the preparation steps of which are basically the same as in Example 1, the only difference being: the composition ratio of raw materials in step 1 is different, that is, the micron-sized hard ceramic particles of silicon carbide The weight percent is 15wt%, the short carbon fiber is 5wt%, and the balance is polytetrafluoroethylene. When stirring and mixing, weigh 22.5 g of silicon carbide, 7.5 g of short carbon fiber, and 120 g of PTFE.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com