Label color band for detecting hydrogen and preparation method thereof

A label and ribbon technology, used in measuring devices, material analysis, instruments, etc. by observing the impact on chemical indicators, can solve the problems of inconvenience of carrying hydrogen sensors, distorted output signals, low safety factor, etc., to improve uniformity. Sensitivity and sensitivity, improved response speed, fast adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The invention provides a method for preparing a label ribbon for detecting hydrogen, comprising the steps of:

[0060] The hydrogen-sensitive label ribbon is obtained by modifying the noble metal quantum dots on the surface of the hydrogen-sensitive material substrate by ultraviolet light reduction method.

[0061] The invention detects the corresponding concentration of hydrogen in the environment by utilizing changes in the reaction structure of the hydrogen-sensitive material and hydrogen to cause changes in optical signals such as emissivity, transmittance, and wavelength. And by using the ultraviolet light reduction method to modify the surface of the hydrogen-sensitive material with precious metals, while increasing the specific surface area of the sensitive layer, the sensitivity of the label ribbon to hydrogen can be improved, and the hydrogen can be absorbed and responded faster.

[0062] In a preferred embodiment of the present invention, the noble metal inc...

Embodiment 1

[0082] The preparation method of the label ribbon for detecting hydrogen described in this embodiment is as follows:

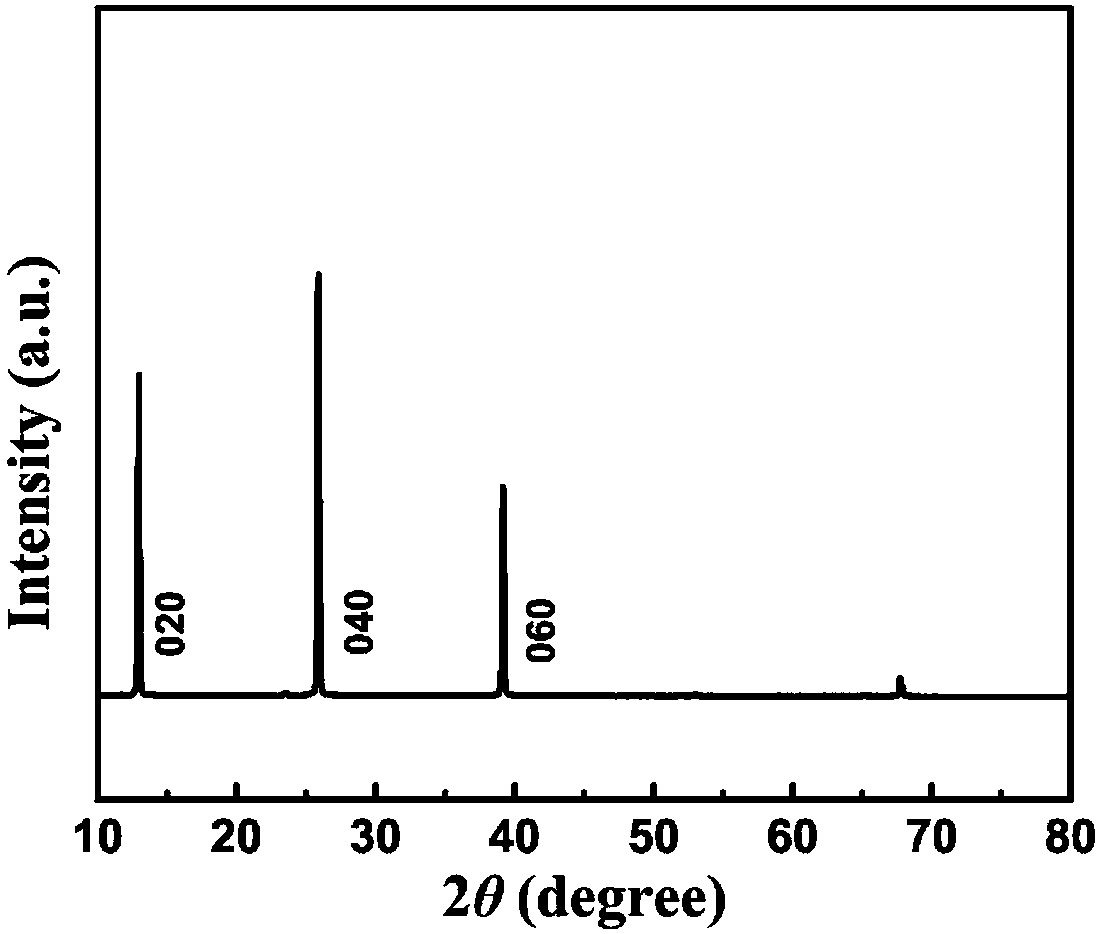

[0083] (1) Dissolve 2.42g of sodium molybdate dihydrate in 30mL of deionized water, then drop into it 6.25mL of concentrated nitric acid (mass concentration is 70±2%), and keep stirring for 30min to obtain precursor solution A; The bulk solution A was transferred to a clean reaction kettle, placed in a constant temperature reaction box at 260°C, and after continuous reaction for 96 hours, it was naturally cooled to room temperature to obtain material B;

[0084] (2) Wash material B with deionized water until neutral to remove MoO 3 After other impurities, the MoO in the solution 3 The nanowires were mechanically stirred for 24 hours to obtain a slurry C; the slurry C was poured into a mold, and dried at a constant temperature of 50°C for 24 hours to obtain a molybdenum oxide nanowire paper substrate;

[0085] (4) 0.003g of PdCl 2 Pour the powder into a clea...

Embodiment 2

[0089] The preparation method of the label ribbon for detecting hydrogen described in this embodiment is as follows:

[0090] (1) Dissolve 2.42g of sodium molybdate dihydrate in 30mL of deionized water, then drop into it 6.25mL of concentrated nitric acid (mass concentration is 70±2%), and keep stirring for 30min to obtain precursor solution A; The bulk solution A was transferred to a clean reaction kettle, placed in a constant temperature reaction box at 260°C, and after continuous reaction for 96 hours, it was naturally cooled to room temperature to obtain material B;

[0091] (2) Wash material B with deionized water until neutral to remove MoO 3 After other impurities, the MoO in the solution 3The nanowires were mechanically stirred for 24 hours to obtain a slurry C; the slurry C was poured into a mold, and dried at a constant temperature of 50°C for 24 hours to obtain a molybdenum oxide nanowire paper substrate;

[0092] (4) Pour the chloroplatinic acid powder of 0.006g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com