Method for detecting content of sulphobetaine surfactant in oil well injection-production fluid through high performance liquid chromatography

A high-performance liquid chromatography and sulfobetaine technology, which is applied in the field of oilfield chemical analysis, can solve the problems of unsatisfactory determination of sulfobetaine surfactant content, cumbersome operation steps, and low sensitivity, and achieve an excellent detection method , good repeatability and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Sample preparation for sultaine surfactant analysis:

[0020] Preparation of standard solution: Weigh 100 mg of sulfobetaine surfactant standard, weigh it accurately, put it in a 1000 ml volumetric flask, add blank oil well injection fluid and dilute to the mark, shake well to obtain a standard solution.

[0021] Preparation of the test solution: Measure 50 mL of the oil well injection fluid sample, measure it precisely, place it in a 1000 ml volumetric flask, add an appropriate amount of blank oil well injection fluid, dissolve it and set the volume to the mark, shake well to obtain the test solution .

[0022] Five copies of each of the standard solution and the test solution were prepared.

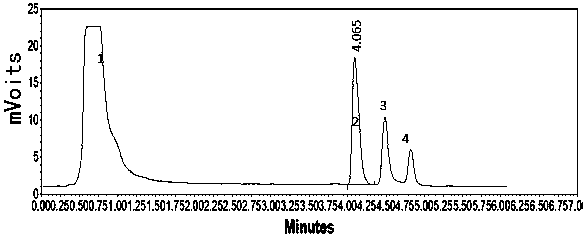

[0023] Chromatographic analysis conditions: Agilent 1100 high performance liquid chromatography, Waters C18 column (50 mm × 4.6mm I.D., 5 μm); mobile phase: methanol, water as mobile phase, gradient elution, 0~2 min 70% methanol , 100% methanol after 2.01 min; injection volume:...

Embodiment 2

[0046] The preparation of standard solution is the same as in Example 1.

[0047] Preparation of the test solution: take 5 mL of the oil well production fluid and shake well to obtain the test solution.

[0048] Five copies of each of the standard solution and the test solution were prepared.

[0049] Chromatographic analysis conditions: Agilent 1100 HPLC, Agilent C18 column (50 mm × 4.6 mm I.D., 5 μm); mobile phase: methanol, water as mobile phase, gradient elution, 0-2 min is 70% methanol , 100% methanol after 2.01 min; injection volume: 20 µL; detector: ELSD; gas flow rate: 2.4 mL / min; evaporation temperature: 118 °C; column temperature: 25 °C.

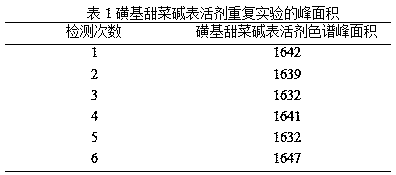

[0050] According to the above-mentioned chromatographic conditions, all standard products and need testing samples were sampled respectively, and the peak area obtained by sample injection of 5 samples of standard solution was 4429 respectively, and the RSD was 0.29%; the average value of the peak areas obtained by 5 samples of te...

Embodiment 3

[0054] The preparation of sample and standard solution is the same as in Example 1.

[0055] Chromatographic analysis conditions: Agilent 1100 high performance liquid chromatography, Agilent C18 column (50 mm × 4.6 mm I.D., 5 μm); mobile phase: methanol, water as mobile phase, gradient elution, 0-2 min is 70% methanol , 100% methanol after 2.01 min; injection volume: 20 µL; detector: ELSD; gas flow rate: 2.2 mL / min; evaporation temperature: 113 ℃; column temperature: 25 ℃.

[0056] According to the above-mentioned chromatographic conditions, all standard products and need testing samples were sampled respectively, and the peak area obtained by sample injection of 5 samples of standard solution was 4420 respectively, and the RSD was 0.25%; the average value of peak areas obtained by 5 samples of test solution was 4464 with an RSD of 0.29%.

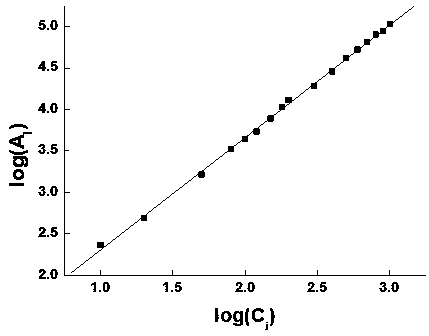

[0057] The concentration of sulfobetaine in the test solution: logM 样 =logM 标 / logA 标 ×logA 样

[0058] Adopt the external standard m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com