Titanium nitride-polypyrrole nano composite material and preparation and application thereof

A polypyrrole nanometer and composite material technology, applied in nanotechnology, nanotechnology, hybrid/electric double layer capacitor manufacturing and other directions, can solve the problems of titanium nitride nanomaterials falling off and unstable, and increase the deposition amount and specific surface area. , The effect of preventing shedding and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

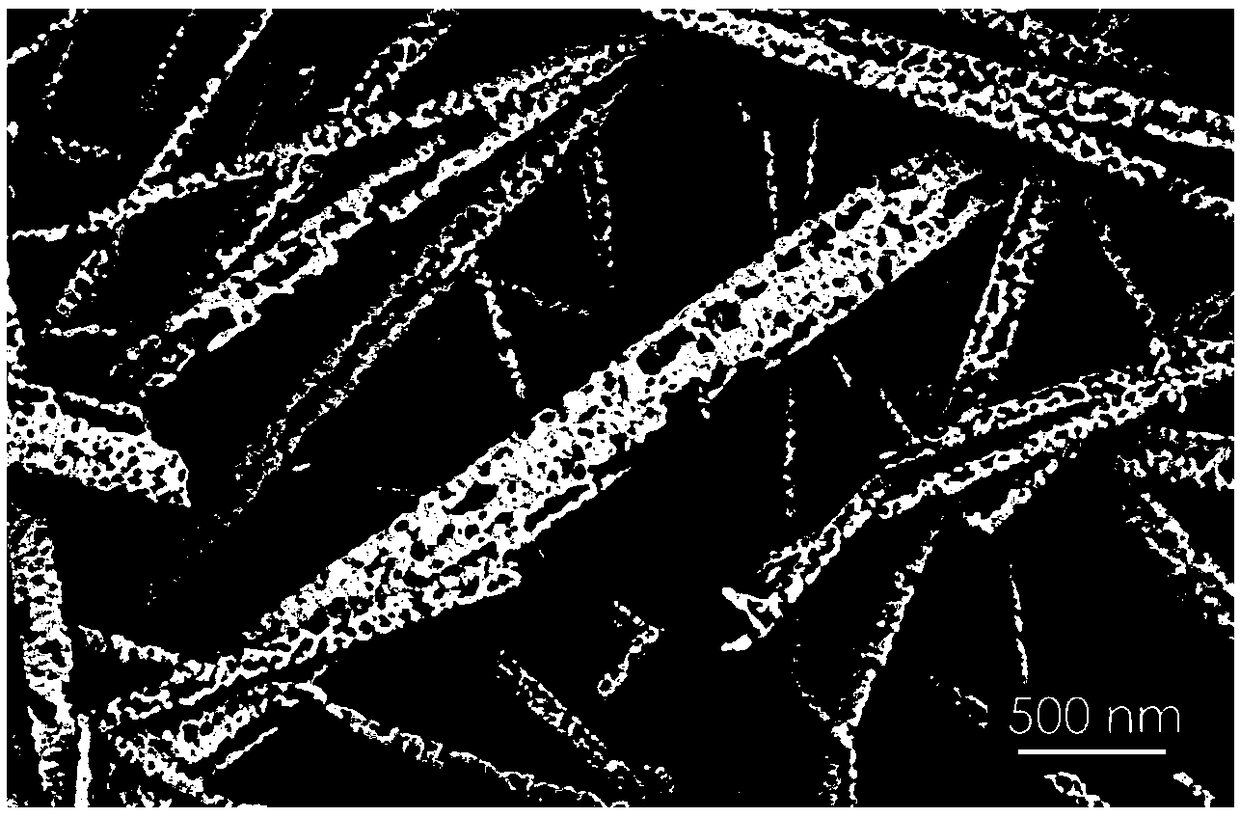

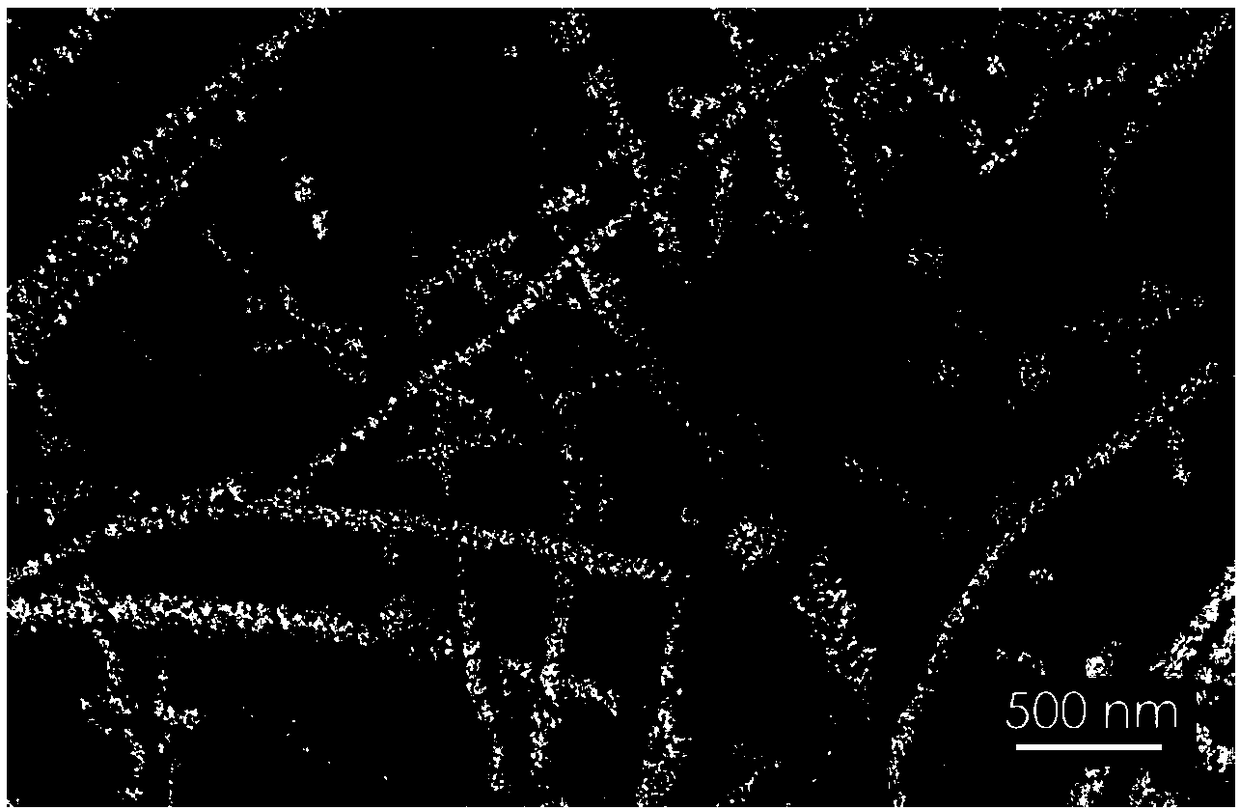

[0059] This embodiment provides a preparation method of titanium nitride-polypyrrole nanocomposite material, comprising the following steps:

[0060] S1. Using carbon paper as a base material, growing a titanium dioxide nanofiber film on its surface to obtain carbon paper loaded with a titanium dioxide nanofiber film;

[0061] Said step S1 comprises the following steps:

[0062] S101. cutting the carbon paper into small pieces of 50mm×20mm×0.20mm, then ultrasonically washing with acetone and water for 10 minutes, and then drying at 80°C to obtain the pretreated carbon paper;

[0063] S102. Take 20 mL of tetrabutyl titanate in a 200 mL beaker, slowly add 100 mL of absolute ethanol while stirring, then add 0.2 mL of glacial acetic acid, and keep stirring at room temperature until the reaction solution is milky white to obtain a titanium dioxide sol;

[0064] S103. immersing the pretreated carbon paper in the titanium dioxide sol, and adsorbing titanium dioxide nanoparticles on ...

Embodiment 2

[0087] In this example, the carbon paper loaded with titanium dioxide nanofiber membrane, the carbon paper loaded with titanium nitride nanofiber membrane, and the titanium nitride-polypyrrole nanocomposite prepared in Example 1 were respectively used as the working electrode, and the platinum sheet was used as the counter electrode. With saturated calomel electrode as reference electrode, with 1mol L -1 Sulfuric acid was used as the test solution, and its electrochemical performance was tested by cyclic voltammetry and galvanostatic charge-discharge method.

[0088] Figure 6 It is the cyclic voltammetry curve figure of the carbon paper supporting titanium dioxide nanofiber film in the present invention under different scan rates, Figure 7 It is the cyclic voltammetry curve figure of the carbon paper supporting titanium nitride nanofiber film in the present invention at different scan rates; the scan rates corresponding to the different curves in the figure are as follows: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com